Nevertheless, dryers burn and explode. Every year 400-500 explosions occur in grain processing facilities worldwide. The most frequent accidents occur in equipment: elevators, dryers, crushers, conveyors and fans (about 50%).

The main source of explosion hazard in storage and processing facilities is combustible dust. Its explosiveness depends directly on the type of plant material and the presence of fine combustible impurities in it.

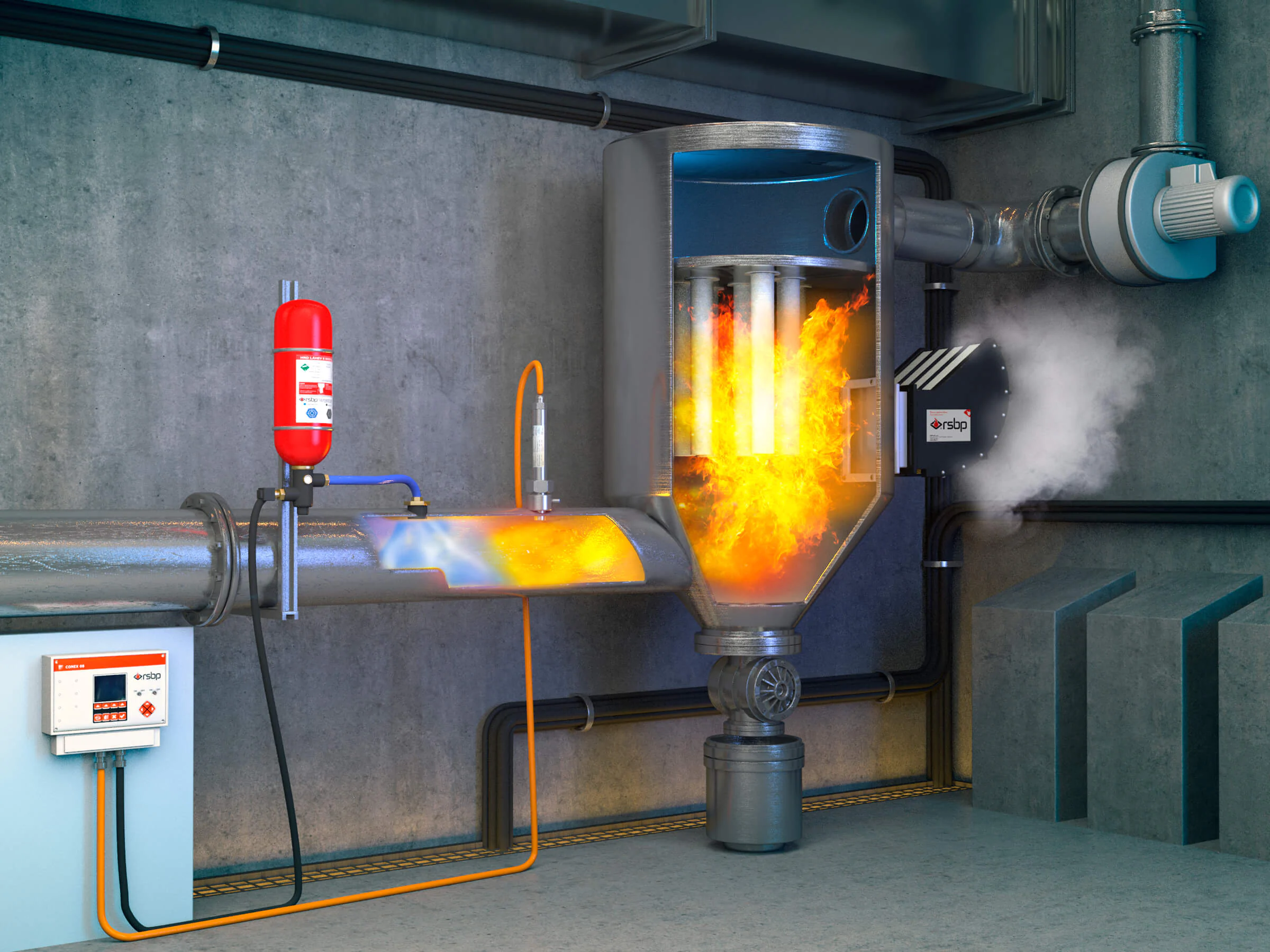

A primary explosion occurs, from which the shock wave propagates the flame and dust-air mixture further. This is followed by a secondary explosion, or even a much more destructive series of explosions.

The storage and processing facilities for plant materials are classified as hazardous industrial facilities (HIFs).

Sources of explosion initiation

In Europe, Russia and Ukraine, the EN 1127-1-2014 standard is in force. It lists 13 active ignition sources which, in contact with a combustible dust/air mixture, can initiate an explosion.

In dryers, ignition may be caused by:

- electrical sparks, e.g. caused by friction between the dirty fan blades and the cover;

- static electricity;

- overheated coolant or surfaces;

- spontaneous combustion of grain;

- sparks from burning fuel;

- short-circuiting;

- sparks during engine start-up;

- sparks from a cigarette when personnel do not follow the safety instructions.

Very often fires and explosions occur due to worn equipment, "human error" and failure to enclose hazardous areas.

Explosion and fire hazards in dryers are virtually unrelated to their design if the equipment is operated correctly and timely maintenance is carried out. It is the drying process in which combustible dust meets the source of initiation that poses the risk.

Safety standards for the owner of a HIF

The minimum explosion protection requirements for hazardous areas, including grain dryers, are laid down in Directive 99/92/EC. This defines an "explosive environment" as a mixture of air under atmospheric conditions with flammable substances in the form of gases, vapours, mists or dusts in which, after ignition, combustion spreads to the entire unburned mixture.

The owner of a HIF must:

- carry out a risk assessment taking into account the probability of occurrence of explosive atmospheres;

- classify and mark hazardous areas with combustible dusts;

- install explosion protection devices on equipment.

The general requirements of Directive 99/92/EC are specified in national legislation.

Technical solutions

We will carry out a risk analysis to select a suitable explosion protection option. We will take combustible dusts for laboratory tests under "controlled explosion" conditions to determine their explosion hazard parameters:

- Low Explosion Level / LEL

- Maximum rate of explosion pressure rise / (dp/dt)max

- explosion class / Kst

- Minimum explosion temperature / MIT

- Minimum ignition temperature / GT

- Minimum explosion energy / MIE

- Oxygen concentration limit / LOC

Knowing these parameters and the location of the dryer, we will design an explosion protection system and select suitable equipment.