Explosion hazard in dust extraction systems

Ventilation is a mandatory part of the production process in industries where combustible dust is present: grain dust, coal dust, metal dust, wood dust. Dust extraction is needed to improve fire and explosion protection of facilities.

Grain dust, on the other hand, is a class 3 dust in terms of toxicity and explosion hazards. Its Low Explosion Limit (LEL) depends on particle size and humidity and varies from 40 to 20 g/m3. Particularly dangerous are fine dusts for which the LEL can be even lower.

In the storage and processing facilities of the former Soviet republics cyclones developed more than 50 years ago are often used for ventilation. They practically do not capture dust with dispersion less than 10 μm, which is the most explosive.

More modern bag filters show a higher efficiency, but may not provide the desired residual dust content either. The reason can be design errors, incorrect installation or the fact that the actual operating conditions were not taken into account.

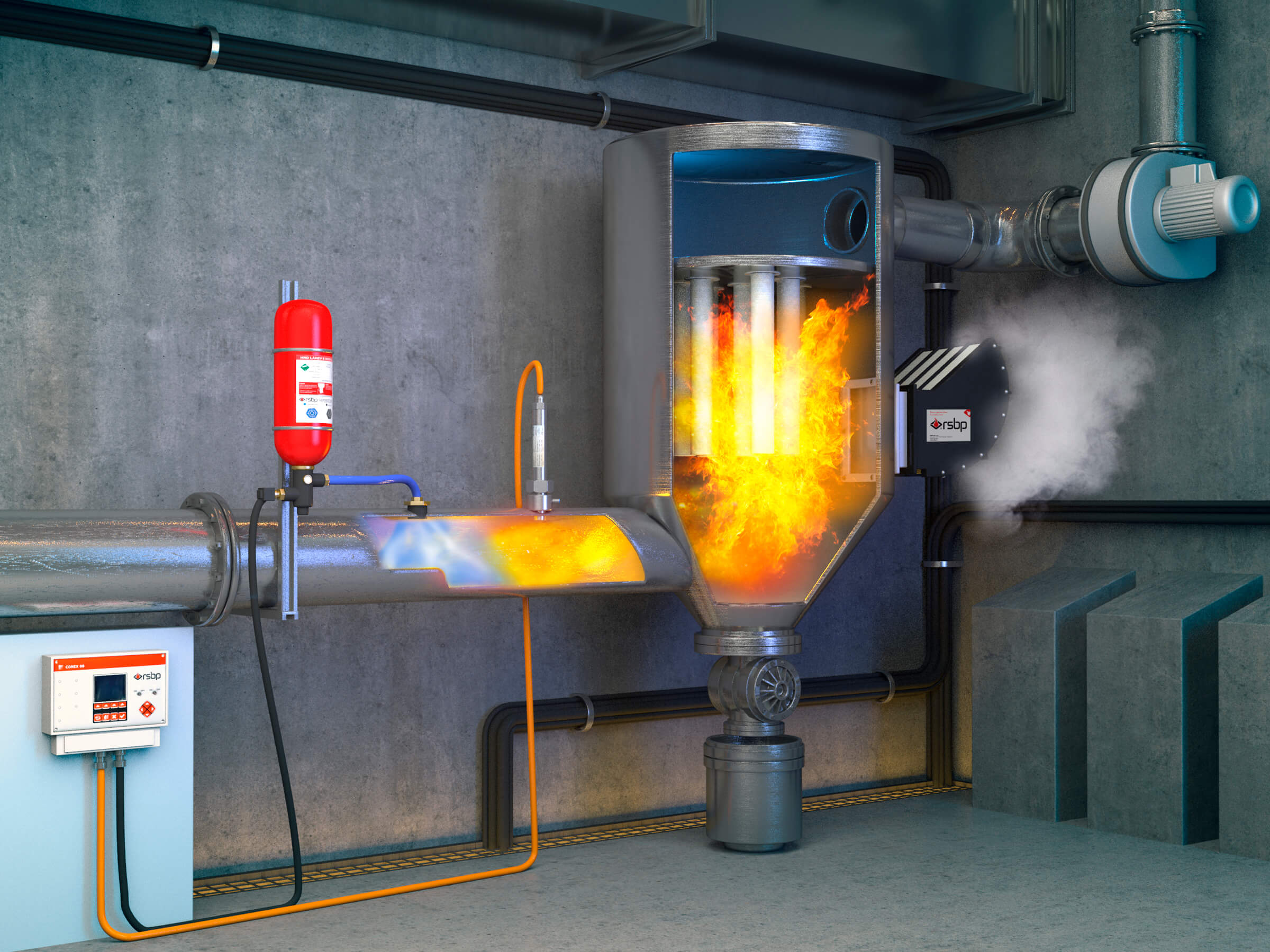

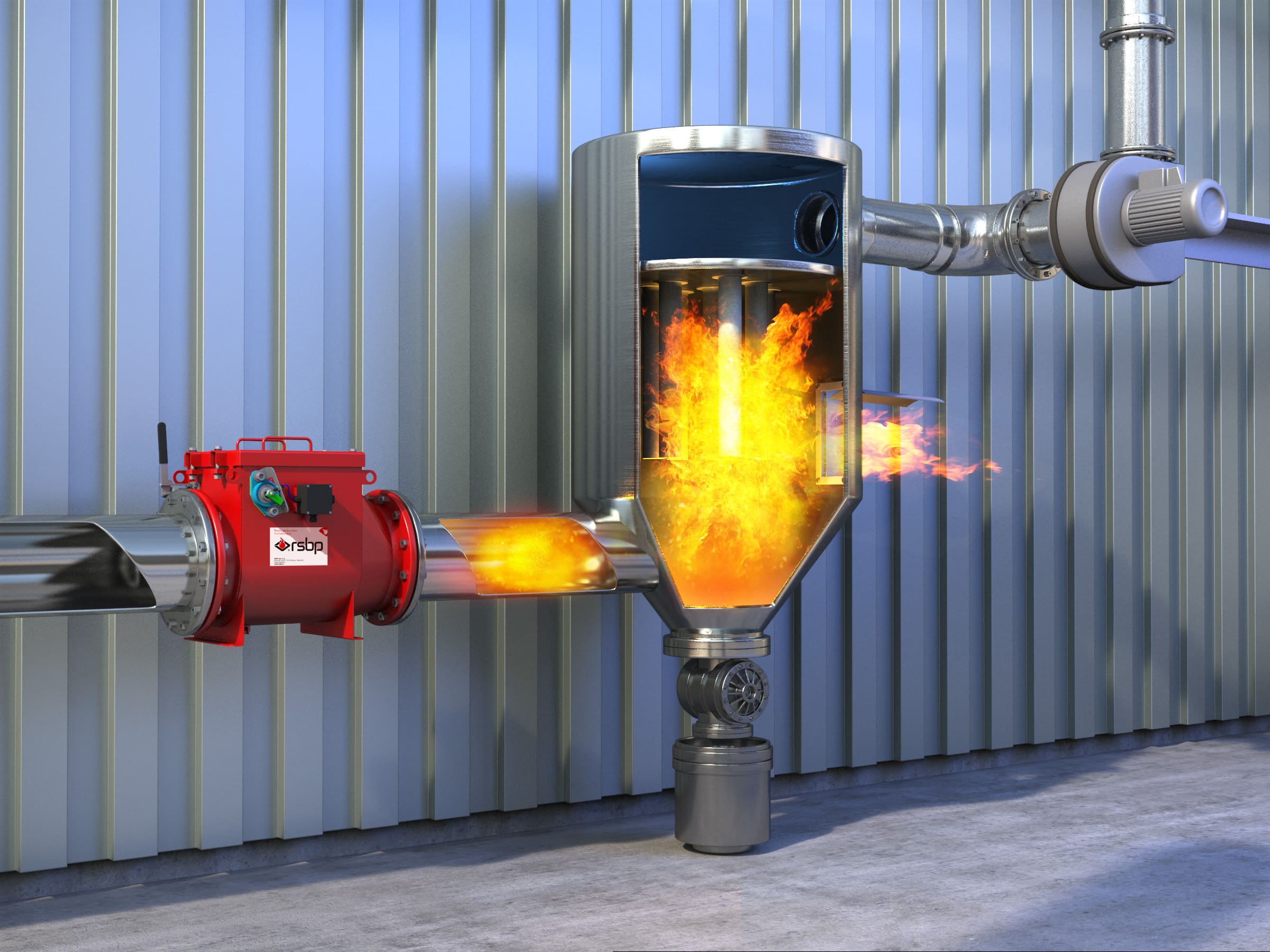

The filters and ducts themselves can become contaminated with combustible dust if they are used incorrectly or if they are installed incorrectly. In contact with the air and the ignition source it causes a primary explosion. The shockwave and flame rapidly travel through the ducts to the unburned dust/air mixture, causing a series of secondary explosions. Accidents in an aspiration system can damage adjacent equipment and rooms where it is installed.

Sources of ignition initiation

EN 1127-1-2014 classifies 13 active ignition sources which, when in contact with a combustible dust/air mixture, may lead to an accident.

What can initiate an explosion in aspiration systems:

- Mechanical sparks from friction;

- Sparks from an electric motor;

- Static electricity;

- Electromagnetic waves;

- Sparks from faulty electrical wiring;

- Fire particles from the external environment entering the air ducts;

- Self-ignition of dust accumulations.

An aspiration system that does not comply with the operating conditions of the site only adds to the explosion hazard problems of the plant. It becomes an additional safety factor.

But a fully functioning, efficient aspiration system also does not prevent an explosion, because combustible dust is always present. Therefore, when planning a ventilation system, Ex-examination should already be considered at 10 % of the NEQ. In the case of grain dust, for example, explosion protection systems are required for dust concentrations from 2 g/m3.

Safety standards for the owner of a hazardous industrial facility

Due to the presence of combustible dusts, storage and processing facilities for raw plant material are classified as hazardous areas. The minimum requirements for their explosion protection are specified in Directive 99/92/EC.

the necessary actions to be taken when operating a hazardous facility:

- Assess the risks taking into account the likelihood of explosive atmospheres;

- Classify and mark hazardous areas;

- Install explosion protection devices on the equipment.

The general requirements of Directive 99/92/EC are specified in national legislation.

ATEX standards provide for explosion-protected versions of aspiration systems:

- The filter housing is reinforced for explosion pressure.

- The overpressure is relieved by means of explosion-proof deflectors and flame arresters.

- Check valves are installed in the intake air duct to cut off the explosion and prevent the propagation of explosion products back to the aspirated points.

The explosion protection systems are selected on the basis of the operating conditions and the characteristics of the materials to be aspirated.

Technical solutions

We first carry out a risk analysis to determine the hazardous area class and the equipment's protection level in accordance with IEC 60079-10-2-2011.

We carry out investigations, including by means of an accredited laboratory. Based on the results, our experts determine the explosion protection parameters of the plant:

- Low Explosion Level / LEL

- Maximum rate of explosion pressure rise / (dp/dt)max

- explosion class / Kst

- Minimum explosion temperature / MIT

- Minimum ignition temperature / GT

- Minimum explosion energy / MIE

- Oxygen concentration limit / LOC

This data makes it possible to select specific explosion protection equipment to suit the operating conditions.

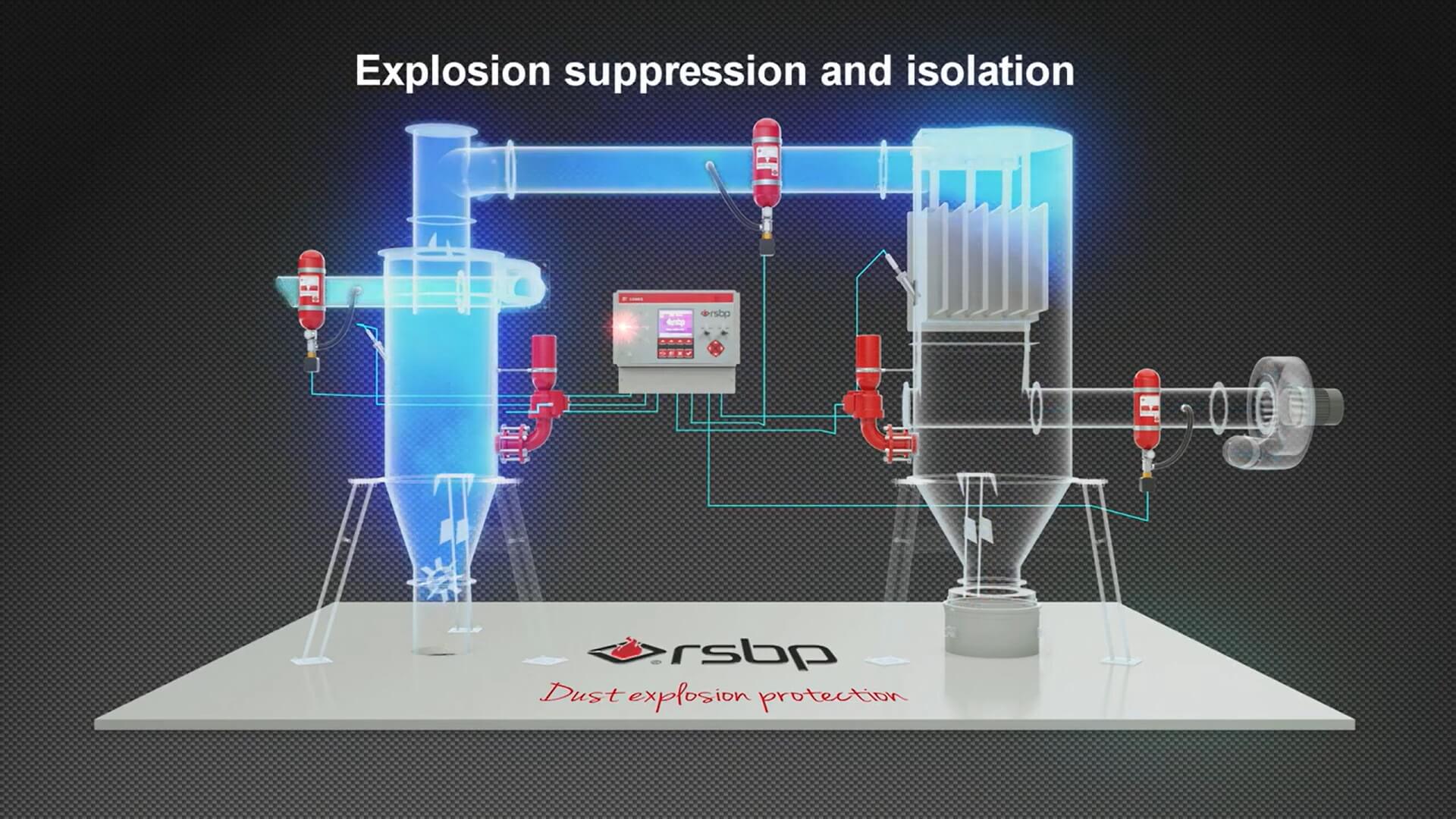

Together with RSBP, we offer four standardised technical solutions for the protection of aspiration systems: explosion suppression and cut-off; release of excess explosion pressure (explosion dischargers); flameless explosion release; explosion cut-off. We adapt them individually to the customer's site.