This is despite the fact that such facilities are classified as hazardous, so there are increased requirements in different countries to prevent accidents. Nevertheless, elevators do explode.

The main cause is combustible dust that forms when transporting grain and other bulk materials. Combined with air it forms an explosive mixture. A single spark causes it to ignite with detonation. Due to the design of the elevator, a primary explosion is usually followed by a series of secondary explosions - devastating in effect and dangerous to people.

According to research data, each batch of harvested grain is moved by bucket elevators an average of 4-5 times. And already after the third lift the content of traumatised grains of dry wheat, barley, oats increases almost by 2,5 times. The concentration of combustible dust increases proportionally.

Sources of ignition initiation

EN 1127-1-2014 classifies 13 active ignition sources which, in contact with a combustible dust/air mixture, may lead to an accident.

In elevators, the cause of the fire may be

- Sparks from a broken elevator belt;

- Heating of individual pipe sections due to friction of the bucket;

- Hot particles in the material to be conveyed;

- Sparks from contact between the edges of the metal bucket and the pipe;

- Static electricity;

- Sparks from the elevator drive;

- Bearing friction, etc.

The list of hazardous situations in nories is quite long. And an explosion cannot be completely ruled out in them - the risk is related to the very process of transporting bulk goods. When the same grain is lifted and dumped, combustible dust is released into the air and forms a dangerous mixture. If it comes into contact with mechanical sparks or static electricity, it causes an accident.

Safety standards for the owner of a hazardous industrial facility

The minimum explosion protection requirements for hazardous areas can be found in Directive 99/92/EC. According to this document, elevators are classified as a hazardous industrial facility as they contain an explosive environment - a mixture of air under atmospheric conditions with flammable substances in the form of dust, in which, after ignition, combustion spreads to the entire unburned mixture.

When operating hazardous facilities, it is necessary to:

- Assess the risks taking into account the likelihood of explosive atmospheres;

- Classify and mark hazardous areas with combustible dusts;

- Install explosion protection devices for the equipment.

General requirements of Directive 99/92/EC are specified in national legislation.

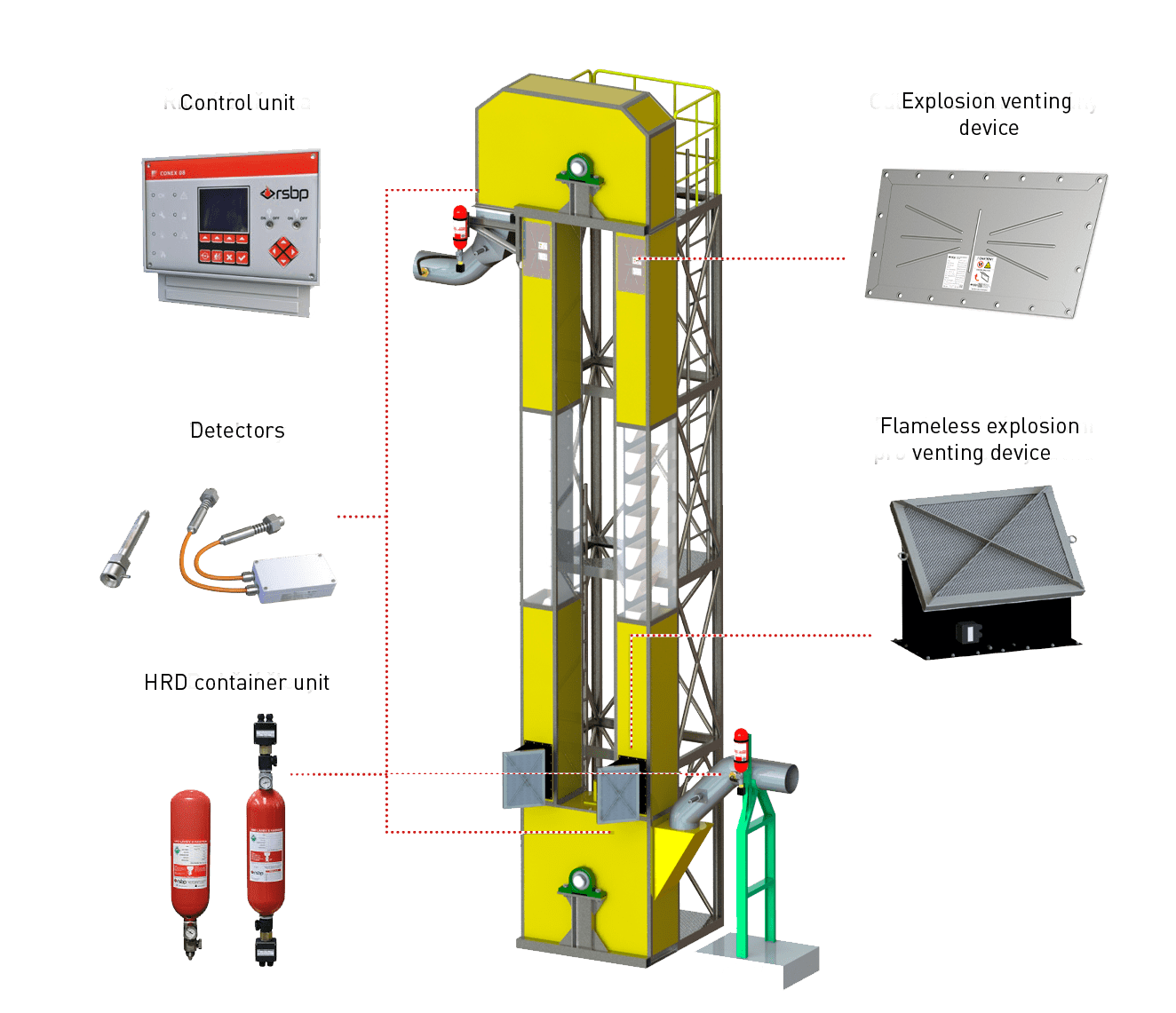

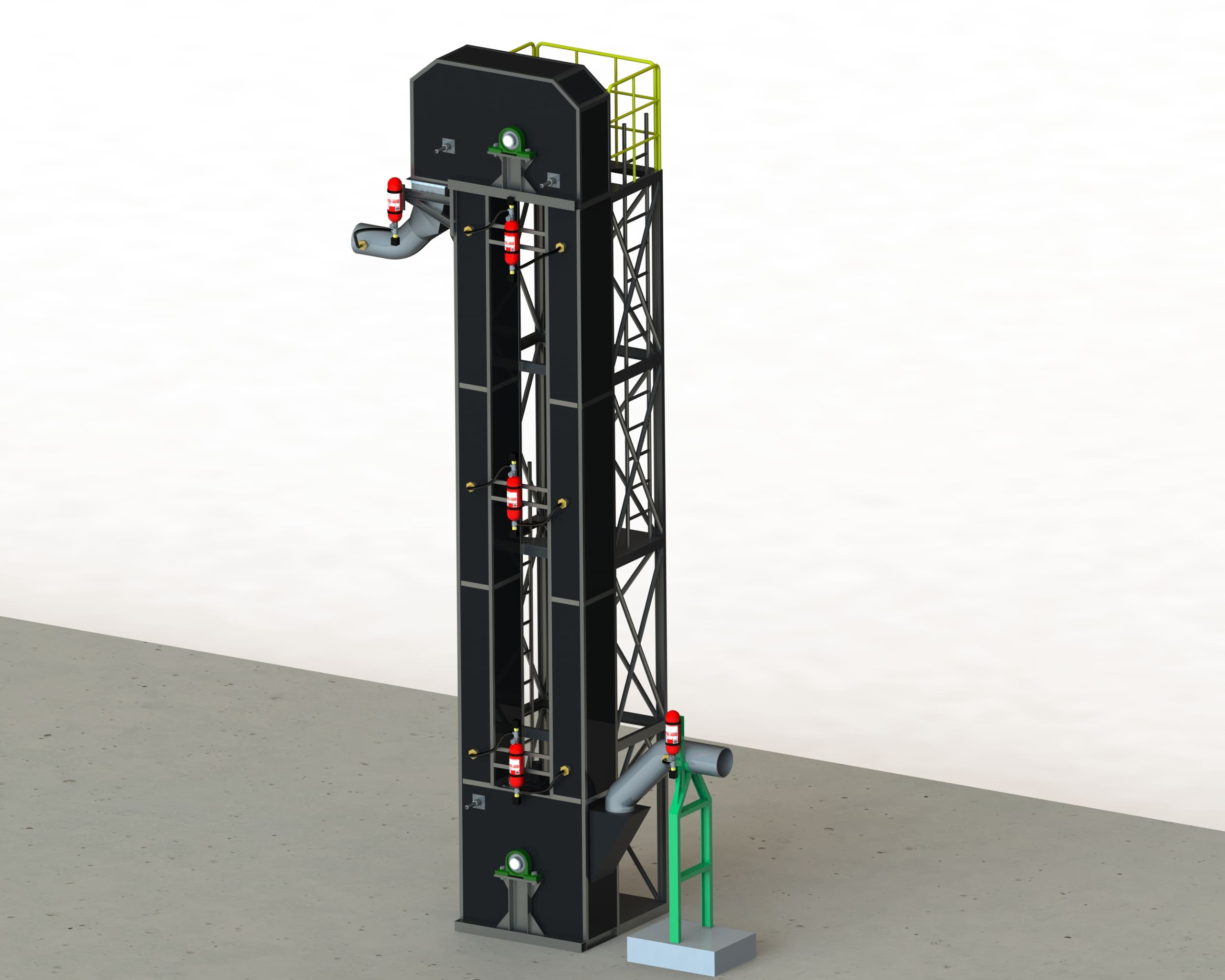

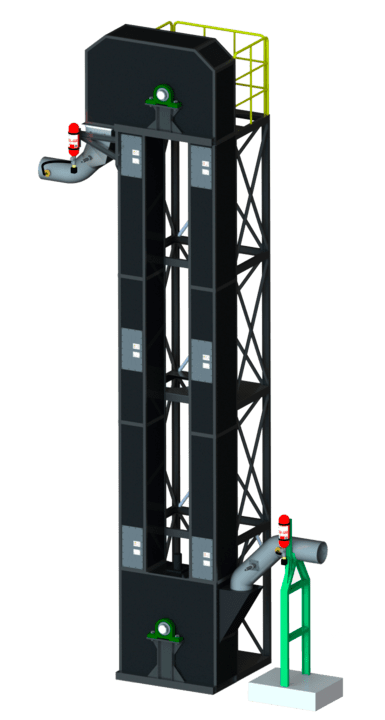

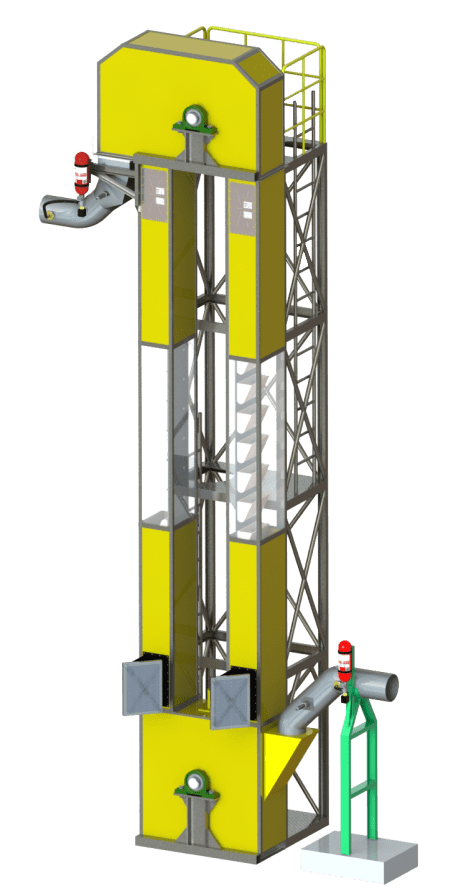

Technical solutions

Explosion protection systems are selected on the basis of the operating conditions and the nature of the material to be conveyed. We therefore first carry out a risk analysis in order to determine the explosion protection class and level of protection in accordance with IEC 60079-10-2-2011.

For this purpose, we take combustible dusts for laboratory tests under "controlled explosion conditions". As a result, we determine the explosion hazard parameters of the production facility:

- Low Explosion Level / LEL

- Maximum rate of explosion pressure rise / (dp/dt)max

- Explosion class / Kst

- Minimum explosion temperature / MIT

- Minimum ignition temperature / GT

- Minimum explosion energy / MIE

- Oxygen concentration limit / LOC.