One of the hazards in industrial production is combustible dust, which creates a potentially explosive environment. People may underestimate its hazards until it leads to an explosion with loss of life and destruction.

Let's find out what combustible dust is and how to protect industrial equipment and personnel from its negative effects. Let's look at its explosion hazard parameters.

What is combustible dust

The international standard IEC 60079-10-2:2015 separates three terms:

- Combustible dust - solid particles with a nominal size of 500 micrometres or less. Combined with air at atmospheric pressure and normal temperature they can form an explosive mixture. Examples: rice and wheat flour, spices, ascorbic acid, aluminium.

- Combustible flyings and fibres with the same properties as combustible dust but larger than 500 mkm in size. Examples: cotton and cotton pulp, hemp, rayon. Combustible flyings and fibres are also classified as 'dust'.

- An explosive dust environment is a mixture of combustible dust and/or combustible flyings and fibres with air under atmospheric conditions in which, after ignition, a self-sustaining flame spreads.

Problems of product explosion in production

Dust itself is an unavoidable by-product of various technological processes. It is generated during the processing and transport of wood, metals or plant material; the production of pharmaceuticals from powdered ingredients. Dust-air mixtures can explode.

Examples of potentially explosive products:

- starch

- cotton

- sugar

- flour

- milk powder

- garlic

- maize

- charcoal

- lactose

- ascorbic acid

- aluminium

- zinc

- carbon black

- polypropylene

Dust becomes dangerous if it forms a cloud with a concentration of combustible particles sufficient to create an explosive atmosphere. This problem is particularly acute in confined spaces.

Layers of combustible dust are dangerous without creating a cloud when in contact with a heated surface or heat source. They can self-ignite and cause ignition on equipment.

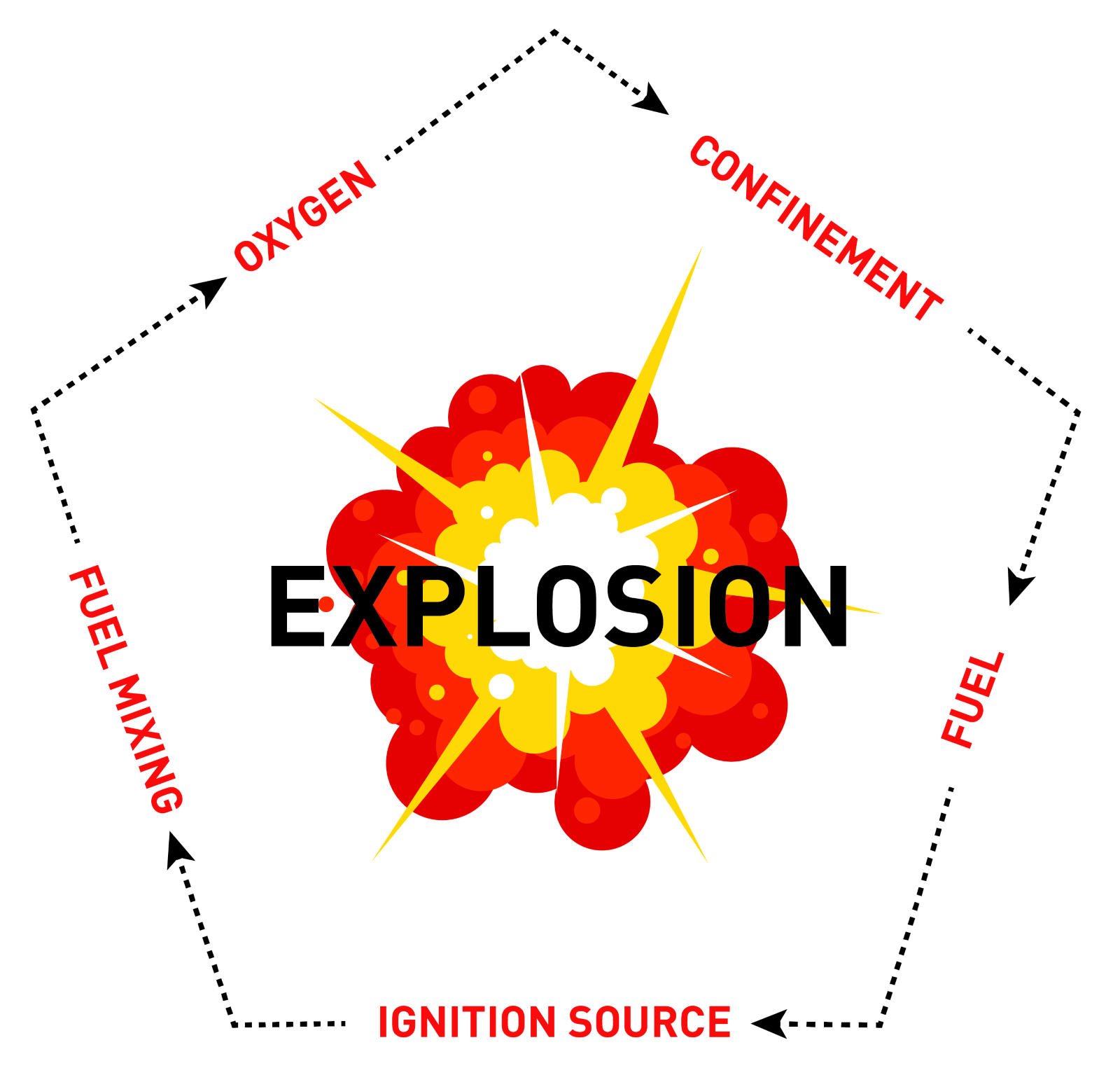

Explosion conditions (pentagon)

Dust always creates a hazard. If an explosive atmosphere (mixture of combustive dust or combustible flyings and fibres with oxidising gases) and a source of initiation (flame, electric discharge, spark) meet in a confined space, an explosion will occur.

A dust/air mixture explodes when several conditions are met:

- Its concentration has fallen into the explosive range, e.g. a cloud has formed when the equipment is switched on after a long interruption;

- There is sufficient oxygen or other oxidising agent;

- It has come into contact with an ignition source.

Primary and secondary explosions often occur. The initial one arises from a small amount of combustible powder or fibres and displaces other solid particles into space. These in turn come into contact with the oxidizer and flame, causing a second explosion, more destructive and powerful. The process happens quickly, so the sequence is not always visible.

Product explosiveness parameters

The flammability of a dust indicates the probability of ignition, but not the probability of an explosion. The probability of an explosion depends on the production technology of the particular product.

The choice of dust explosion protection depends on the parameters of dust explosiveness. These, in turn, are determined by several characteristics, including dispersibility and concentration. Their correlation determines the explosiveness of a combustible dust.

Dispersibility is the degree to which the product is ground. The smaller the particles, the greater the total surface area of the substance. This in turn affects the chemical and physical activity of the dust and its dispersion in the air. Smaller particles react faster with oxidising agents and are less likely to deposit on surfaces.

Concentration is the ratio of the mass of powder to the volume of air (g/m3). The ignition temperature is related to this parameter. Each type of a combustible dust has its own explosive concentration range, with an upper and lower limit.

The smaller the combustible particles, the lower their content can cause an explosion. There is also a dependence on the shape of the combustible dust. Spherical particles oxidise more slowly than irregular ones.

The explosiveness of combustible dust depends on:

- dispersion;

- particle shape;

- moisture content of combustible dust;

- explosive concentration range;

- content of anti-ignition substances.

There are no ready-made guides to the explosion hazard of powders in a particular production facility, so it depends on several conditions. Professional laboratory tests are needed to find out the risks. In ATEX.CENTER tests, combustible dust samples are ignited and explode under controlled conditions. The entire process is measured and analysed.

Product explosion risk assessment

In order to know the risks of individual production, two procedures are carried out:

- dust testing.

- explosion safety audits of premises and equipment.

The explosion risk class of the combustible dusts generated in the plant can be determined by testing the explosion protection system in the laboratory. This will determine the choice of explosion protection for the equipment. It is possible to select an explosion protection system without performing an explosion test on the basis of the available reference data, but in the event of a large volume of dust explosion protection needs, the choice of explosion protection system will be inaccurate. It is like selecting a treatment from a doctor without an examination.

Specialists measure and calculate the following key indicators to determine the parameters of the explosion hazard:

The LEL — is the Lower Concentration Limit of Flame Propagation of an Aerosol Mixture. Indicates the minimum concentration of a dust/air mixture for combustion.

UEL — upper explosive limit of flame propagation through the air suspension. The wider the range of the LEL and UEL, the more explosive the dust/air mixture is.

Pmax — maximum explosion pressure.

(dP/dt)max - maximum rate of rise of explosion pressure.

Kst — Combustion explosion severity index (explosion index).

See table for explosion hazard classes of combustible dusts.

| The explosion hazard class | Kst value, bar*m/s | Explosive power | Examples of substances |

|---|---|---|---|

| St0 | 0 | No | Welding dust |

| St1 | 0-200 | Weak | Milk powder; sugar; zinc |

| St2 | 200-300 | Strong | Cellulose, PMA |

| St3 | от 300 | Very strong | Titanium, magnesium powders |

To determine Kst and Pmax, a 'controlled explosion' is needed. This can only be done safely under laboratory conditions. We do this with our partners, the leading European institutes for explosion protection.

Audits help to identify and mark areas in the workplace where there are accumulations of combustive dusts; to clarify the volume and nature of the dust/air mixture formation - permanent or temporary. Such areas are classified according to their hazard level. This is used to identify areas where explosion protection is to be installed.

It is best to commission an audit from an expert organisation, e.g. ATEX.CENTER. Dust accumulations cannot always be found visually, because they can also be inside the equipment. This is why explosion protection specialists, together with the customer's technical personnel responsible for the specific process, carry out the audit.

Actions to be taken if there is a possibility of product explosion

The process owner must design and implement measures to protect people and equipment:

- avoid, if possible, the formation of layers and accumulations of product;

- remove sources of ignition;

- issue flame-retardant clothing to personnel, if necessary;

- install explosion protection systems where it is not possible to get rid of combustible dust completely.

ATEX.CENTER offers a complete explosion protection service. We will test the explosion protection system for you, conduct audits, develop protection measures and, if necessary, propose solutions and deliver the right equipment. Our expert centre is an official partner of the leading European manufacturer of explosion protection systems RSBP spol. s r.o.

You can order a turnkey dust-air mixture explosion protection project or individual works.