We care about your safety

ATEX.CENTER is an expert center for explosion protection of production facilities with explosive dust/air mixtures and risks of explosion due to overpressure of flammable liquids and gases in equipment. Our specialists provide a range of services on a turnkey basis, from design to commissioning.

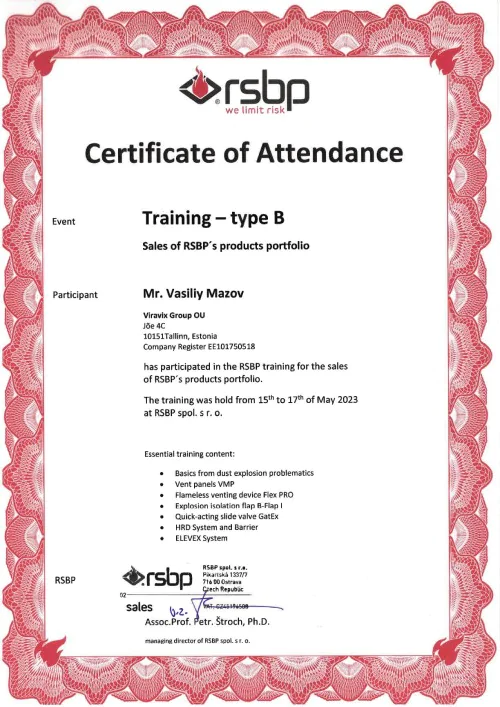

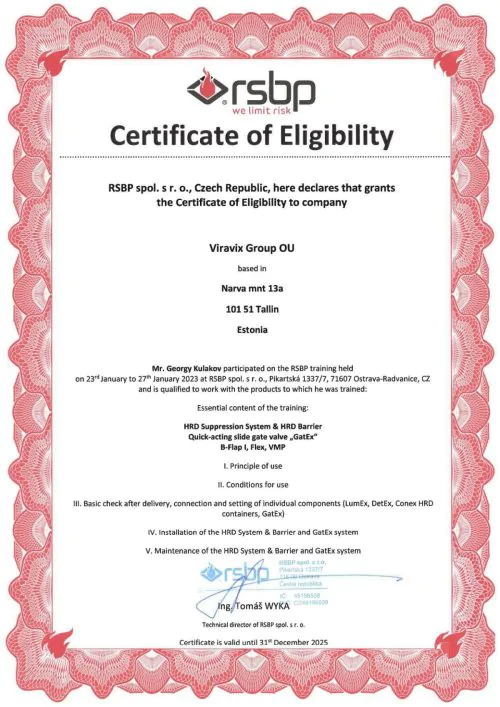

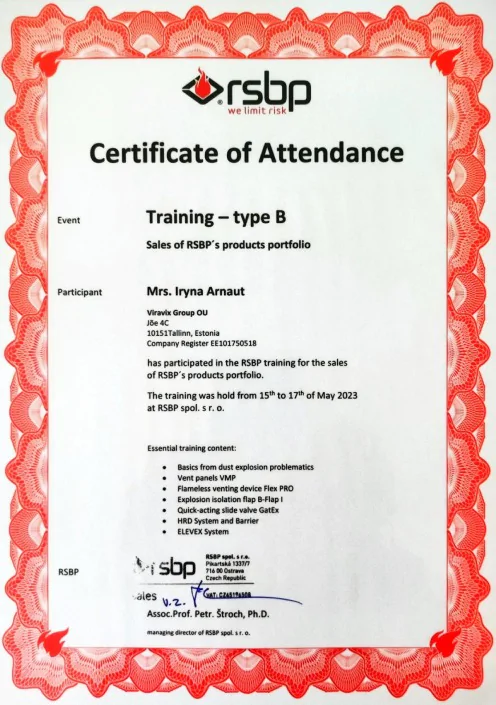

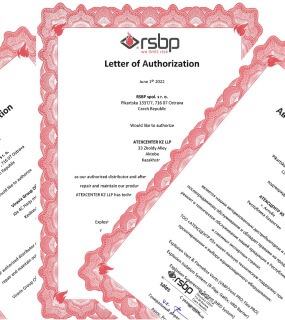

Since 2019, ATEX.CENTER has been an official partner of RSBP spol. s.r.o., a European manufacturer of explosion protection systems.

Since 2024, ATEX.CENTER has been an official partner of FDC Co., Ltd., a South Korean manufacturer of bursting discs.

ATEX.CENTER is an integrator of European explosion protection systems, which provides a full range of work on the explosion safety of the turnkey object: from risk analysis to service maintenance.

For whom we work

ATEX.CENTER specializes in complete solutions for combustible dust explosion protection. For us, the safety of people in production comes first, so we are open to cooperation with industrial companies as well as their suppliers and contractors.

"The company's core value is confident and inspired employees."

Vasily Mazov,

CEO of ATEX.CENTER

Our services will be useful for:

Large owners of hazardous production facilities (HPF) of woodworking, metallurgical, food, agrarian, energy, pharmaceutical, chemical industries. Their technological processes often contain combustible dust, which in contact with oxygen and ignition sources leads to explosions.

ATEX.CENTER experts will assess the risks in production, design and organize the installation of systems for protection against explosion of dust-air mixtures. We save the customer's stuff’s lives and material assets.

General contracting organizations that build hazardous industrial facilities.

ATEX.CENTER engineers will offer explosion protection design solutions, ensure explosion protection at any stage of construction, analyze the existing project for compliance with regulatory requirements. We will coordinate technical solutions with the supervisory authorities ourselves.

Manufacturers of aspiration systems, filters, where explosion protection is required.

ATEX.CENTER's explosion protection solutions ensure the safe operation of your devices. We keep aspiration systems and filters economically attractive for our customers.

What you get in cooperation

with ATEX.CENTER

You can choose one service or order a complex, depending on your production protection needs.

ATEX audit (Explosion Risk Assessment)

- LEL | lower explosion limit of flame propagation through air suspension

- Pmax | maximum explosion pressure

- (dp/dt)max | maximum rate of explosion pressure rise

- Kst | Dust Explosion Description Number

- MIT | minimum ignition temperature

- GT Minimum Combustion Temperature

- MIE | minimum explosion energy

- LOC | limiting oxygen concentration rate

A “controlled explosion” is needed to establish these values. It can only be done safely under laboratory conditions.

Implementation of turnkey explosion protection systems

The customer gets the whole complex of works:

- Explosion safety analysis

- Design of explosion protection systems

- Recommendations for explosion prevention

- Equipment delivery

- Installation and commissioning

We work according to the requirements of the ATEX 153 99/92/EC, ATEX 114 2014/34/EU directives and the European standards EN 1127-1, EN 14373, EN 14491, EN 14797-2017, EN 15089, EN 16447, EN 16009-10-2, EN 50281-3, EN 12779, CEN/TR 16829.

Maintenance of explosion protection systems

We do not leave the customer after the work is done. ATEX.CENTER engineers will help to keep the explosion protection system working to prevent catastrophic consequences in case of an accident in production.

ATEX consulting

The experts at ATEX.CENTER support the direct manufacturer of the equipment. This gives us the right to advise you on all ATEX issues and help you manage the explosion safety of your plant.

What technical solutions we offer

ATEX.CENTER is an official distributor of RSBP spol. s r.o. We supply products from the manufacturer of explosion protection systems with 30 years of experience.

What RSBP is known for:

- The company tests a variety of industrial equipment for safety at its own research facility. Its engineers will blow up the unit themselves to come up with a way to protect it. But RSBP customers will be assured that this device will not blow up at their facility.

- In addition to the polygon, RSBP spol. s r.o. has its own experimental site for testing and demonstrating solutions to customers and partners, a research laboratory for current developments and a training center for staff development.

RSPB is one of the few companies in the world that gives a 100% warranty on its dust-air mixture explosion protection systems.

Explosion protection solutions from RSBP table

If the operating pressure inside the equipment is exceeded, a panel on its surface opens and relieves the pressure from the danger zone.

When the pressure in the tanks rises above Pstat 0.05 bar, the explosion door opens and the excess pressure is released into the environment. Can be used repeatedly.

They consist of an explosion vent panel and an outer casing with a scattering surface. When triggered, the released products (burning dust, shock wave) pass through the grid system in the scattering surface. As a result they are cooled down and decelerated to values that are safe for personnel and nearby equipment

Registers an accident in equipment at the nucleation stage with highly sensitive sensors and effectively extinguishes it by introducing an explosive suppressant

Consists of the same components as the HRD-system, but a comprehensive approach in the selection and arrangement of cylinders allows to localize the accident, suppress ignition and explosion, and block the shock wave

Prevents an explosion from spreading between connected pieces of equipment by closing and locking the gate by the air shock wave

It closes the pipeline in case of an emergency. An activation signal is sent from the CONEX controller to the gate valve. The gate is activated in the shortest possible time by a high-speed pneumatic actuator

Consists of VMP, FLEX, HRD, B-flap.

Flexible system that can be installed on existing equipment in case of modernization. Characterized by a high variability of design

What are the stages of ATEX.CENTER’s work

- Evaluate the explosiveness of the process and equipment.

- We will select the explosion protection solution in accordance with the current legislation in the field of industrial safety, the customer’s wishes and the manufacturer’s recommendations.

- We will select the explosion protection solution in accordance with the current legislation in the field of industrial safety, the customer’s wishes and the manufacturer’s recommendations.

- Prepare the project and coordinate it with the supervisory authorities.

- We deliver protection systems anywhere in the country.

- We will install the equipment or monitor the quality of installation work from third-party contractors.

- We will carry out commissioning of explosion protection systems.

- Provide service and warranty support.

ATEX.CENTER will take care of the effective explosion protection of your production.

ATEX.CENTER principles

Our Story:

2014 — the Viravix engineering company highlights the direction of protection against industrial dust explosions. An expert center is established.

2019 — ATEX.CENTER engineers confirm qualification and right to officially represent distribution services on behalf of RSBP spol. s r.o.

2022 — opens a representative office in the Republic of Kazakhstan.

Over the years, the company ATEX.CENTER has developed five basic principles of its work:

- Expertise. We employ only certified experts in the field of implementation and service of explosion protection systems.

- Locality. We open representative offices where our clients are. That’s why we respond quickly to their problems.

- Reliability. Explosion protection devices are tested by the manufacturer at the manufacturer’s own testing facility. In our practice there were no cases when the system did not work. In addition, we collect reports on all cases of equipment tripping and send them to the manufacturer to improve the protection characteristics.

- Comprehensiveness. We love turnkey projects, because that way we are responsible for every step and are 100% confident in your protection.

- European experience. We work in liaison with European experts in the field of ATEX.

Why you can trust us

ATEX.CENTER is an official distributor of the leading European dealer of explosion protection equipment RSBP spol. s r.o. Our specialists periodically confirm their qualification in his commission of knowledge verification.

In cooperation with the RSPB, we have implemented more than 20 large-scale projects for explosion protection of equipment. Thanks to well thought-out solutions, we were able to prevent more than 1,260,000 euros worth of damage and save the lives of more than 600 employees in 5 companies.

We give all customers the opportunity to visit the RSBP test site in the Czech Republic to see explosion protection systems in action.

The RSBP explosion protection mark on your equipment is a guarantee of your company’s safety