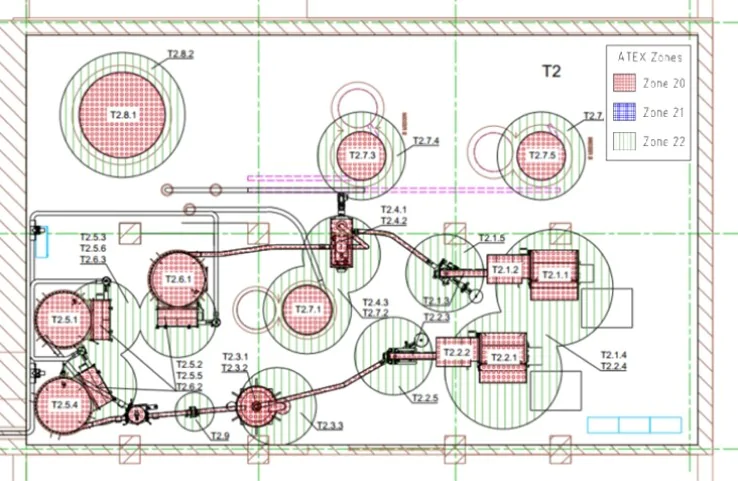

The greatest risk of explosion in such plants is associated with aspiration systems where explosive concentrations of combustible dusts are constantly observed. Depending on the nature of the organic dust and the configuration of the process equipment, different explosion protection systems for aspiration systems can be selected.

Ensure the safety of your enterprise with ATEX.CENTER, your trusted partner in explosion protection solutions. From explosion isolation valves to Flameless explosion venting devices flex, we offer a comprehensive range of products designed to safeguard your operations.

Our lineup includes top-of-the-line explosion venting panels, HRD explosion suppression systems, and the innovative System HRD. With our cutting-edge technology and expertise, you can mitigate the risk of explosions effectively.

Don't compromise on safety. Choose ATEX.CENTER for reliable explosion protection solutions that prioritize the well-being of your facility and personnel. Contact us today to learn more.

ACTIVE EXPLOSION PROTECTION

- Suppressing an explosion by early detection of an explosion and introducing an explosive suppressant into the equipment (HRD system).

- Explosion suppression is the prevention of explosion propagation between connected pieces of equipment by introducing an explosive suppressant into the piping (HRD barrier).

PASSIVE EXPLOSION PROTECTION

- Release of explosion by means of a device for releasing overpressure and explosion products into the environment - explosion vent (VMP explosion vent panels, FLEX flame arresters).

- Explosion cut-off valve, triggered by overpressure and air flow and shutting off the piping between the connected pieces of equipment (B-flap).

Our team has a proven track record in explosion protection for aspiration systems in wood processing plants. You can find out more about our projects in the PROJECTS section.