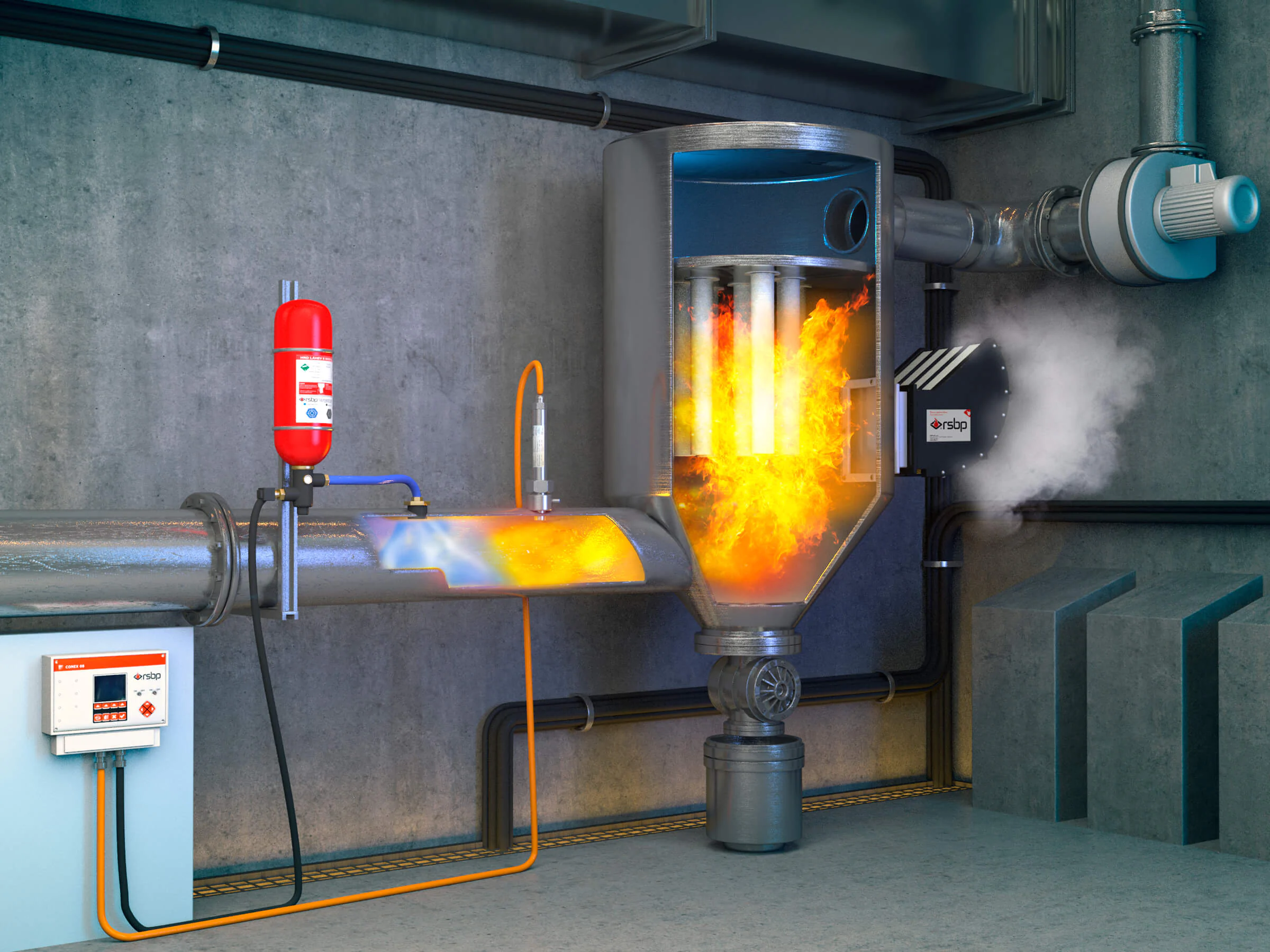

Uncontrolled pressure buildup is one of the most critical safety risks in industrial environments. Whether caused by a chemical reaction, dust ignition, thermal expansion, or equipment failure, overpressure can lead to explosions, fire, and extensive damage.

At ATEX.CENTER, we provide certified solutions that safely relieve excess pressure — protecting people, equipment, and production continuity. Our systems are designed according to international standards (ATEX, EN, NFPA) and tailored to your facility’s specific needs.

What Causes Overpressure?

Overpressure can develop within equipment or pipelines in a matter of milliseconds. Common causes include:

- Explosion of gas, dust, or vapor mixtures due to ignition from sparks, friction, or heat.

- Ventilation or pipeline blockages causing pressure buildup.

- Thermal expansion of gases or liquids in sealed vessels.

- Process failures such as pump malfunctions or incorrect media feeds.

- Pressure wave propagation from explosions in connected equipment.

Even one of these factors is enough to require reliable pressure relief equipment.

What Happens If You Don’t Protect Against Overpressure?

Ignoring the risk of overpressure can lead to catastrophic outcomes — both technically and financially. A single incident can destroy equipment, injure personnel, and halt production for weeks. Here are the real consequences of missing or inadequate protection:

- Equipment destruction. Pressure spikes can rupture filters, silos, ducts, or vessels — often beyond repair.

- Personnel injury. Shockwaves, flying debris, and hot gases put workers at serious risk of injury or fatality.

- Fire and secondary explosions. Uncontrolled pressure release can ignite dust or vapors in adjacent systems.

- Production downtime. Unexpected shutdowns can last days or weeks, with major financial losses.

- Legal and regulatory penalties. Violations of ATEX or EN standards may lead to fines, legal claims, or loss of insurance coverage.

What Is Overpressure Protection Solutions?

Explosion protection systems for overpressure are designed to safely relieve excess pressure in case of an explosion or system failure. Our solutions include:

- Rupture Discs

- Explosion Vent Panels

- Flameless Venting Systems (FLEX)

Solution 1: Rupture Discs

Protection against gas or liquid overpressure in sealed systems

Rupture discs are precision-engineered metallic membranes that burst at a set pressure, allowing immediate pressure relief. Ideal for pressure vessels and pipelines, especially in aggressive or high-temperature conditions.

Key Benefits:

- Instant and accurate activation

- Absolute leak-tightness before rupture

- No moving parts, maintenance-free

- Chemically and thermally resistant

Applications:

- Reactors and pressure vessels

- Pumping stations

- Gas and liquid pipelines

- Other sealed process equipment

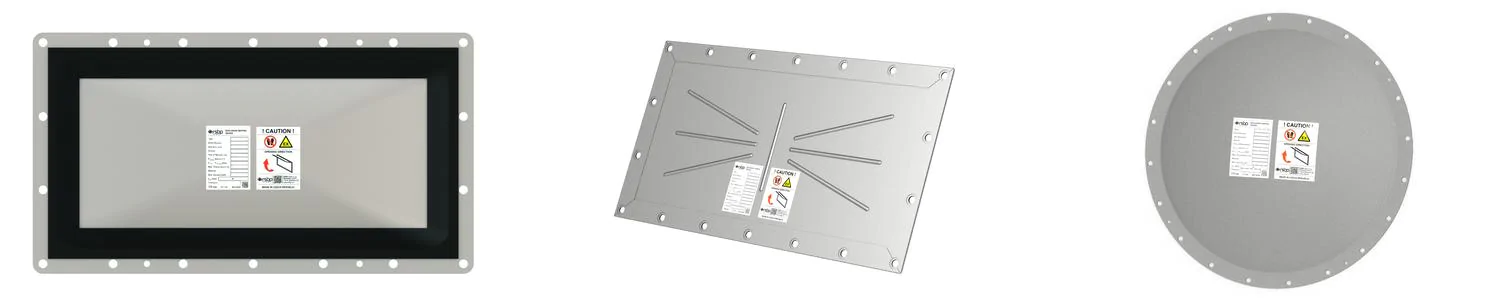

Solution 2: Explosion Vent Panels

Controlled explosion relief for dust and gas atmospheres

Explosion vent panels are designed to burst at specific pressures, directing the explosion force and flame to a safe area. They are commonly used in combination with other explosion isolation devices.

Key Benefits:

- Reliable activation at set pressure

- Custom sizes and configurations

- EN 14797, NFPA 68 and ATEX certified

- Available with insulation, hygienic finishes, vacuum support

Applications:

- Cyclones

- Bag and cartridge filters

- Dryers and silos

- Other explosion-prone process equipment

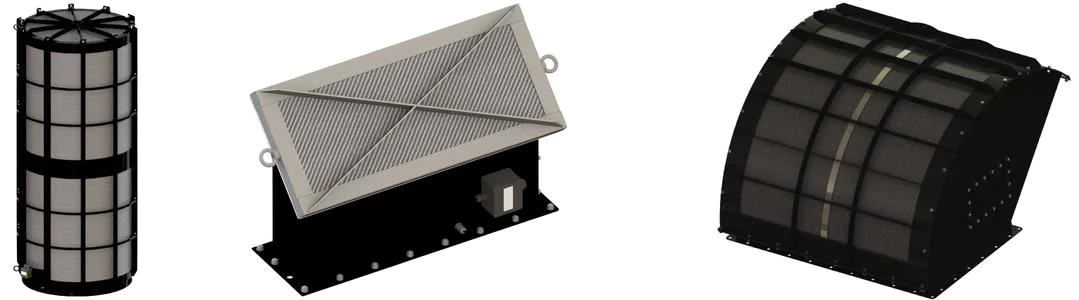

Solution 3: Flameless Venting (FLEX)

Indoor-safe explosion venting without flame release

The FLEX system combines an explosion panel with a flame arrestor to cool and extinguish the flame front, enabling safe indoor installation.

Key Benefits:

- Eliminates flame and heat hazard

- Designed for use inside buildings

- EN 16009, NFPA 68 and ATEX certified

- Compact and integrable into existing equipment

Applications:

- Dust collection filters

- Cyclones and silos

- Aspiration and conveying systems

- Other equipment requiring flameless indoor explosion relief

Compare Our Solutions

| Solution | Medium | Flame Suppression | Indoor Use | Typical Applications |

|---|---|---|---|---|

| Rupture Disc | Gas / Liquid | No | Yes | Sealed vessels, pipelines |

| Explosion Vent Panel | Dust / Gas | No | No | Filters, silos, dryers |

| FLEX (Flameless Vent) | Dust | Yes | Yes | Indoor filters, aspiration systems |

Conclusion

Protecting your equipment from overpressure is not just about compliance — it's about operational safety, business continuity, and saving lives. Whether you’re handling gas, liquid, or dust hazards, ATEX.CENTER offers tailored, certified solutions that meet international safety standards.

From rupture discs and explosion vent panels to advanced flameless venting systems, our engineers help you choose the right protection for your application.