When is a Rupture Disc Required

- During sudden pressure spikes from runaway reactions or thermal expansion

- When system integrity must be preserved in case safety valves may malfunction

- In environments where even minimal leakage is unacceptable

- When handling highly corrosive or aggressive process media

- Where large relief capacity is required in an instant (e.g. polymerization)

- Under severe temperature conditions — both high and low

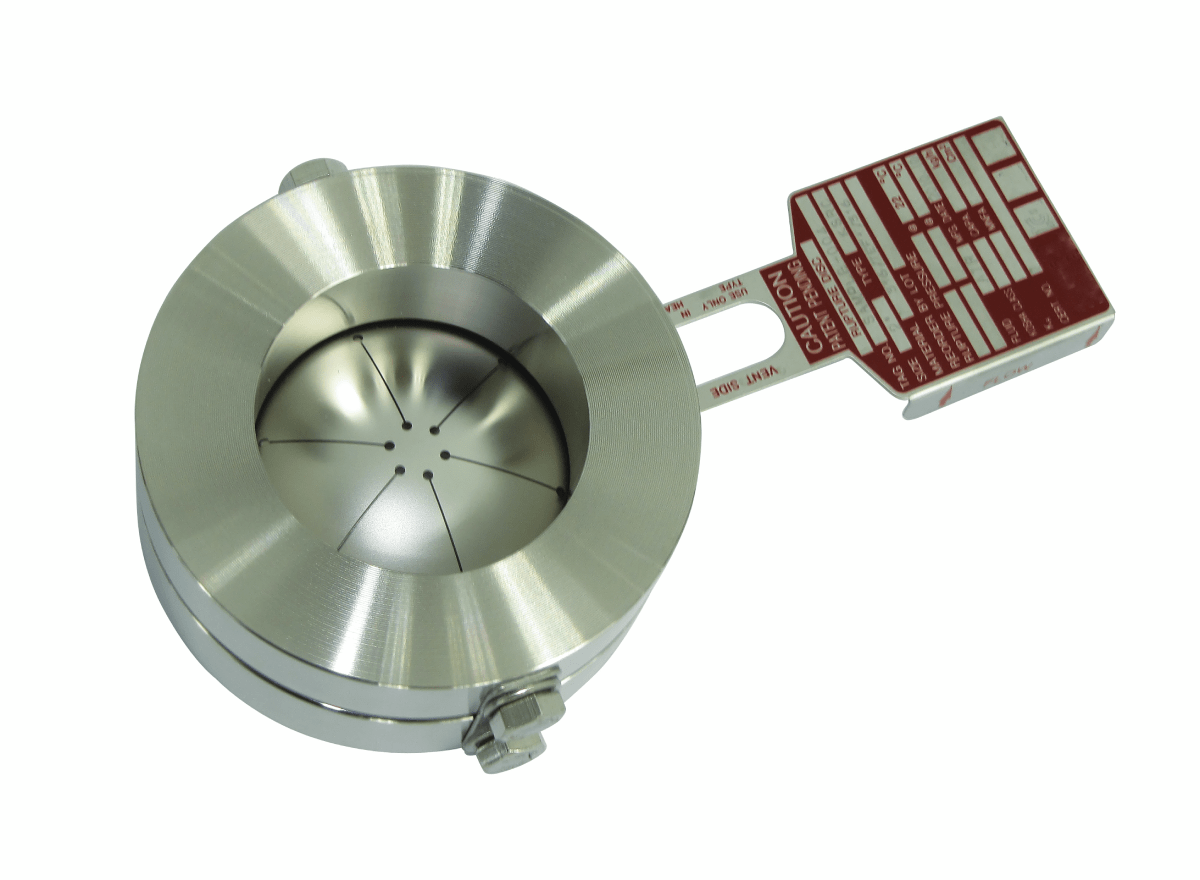

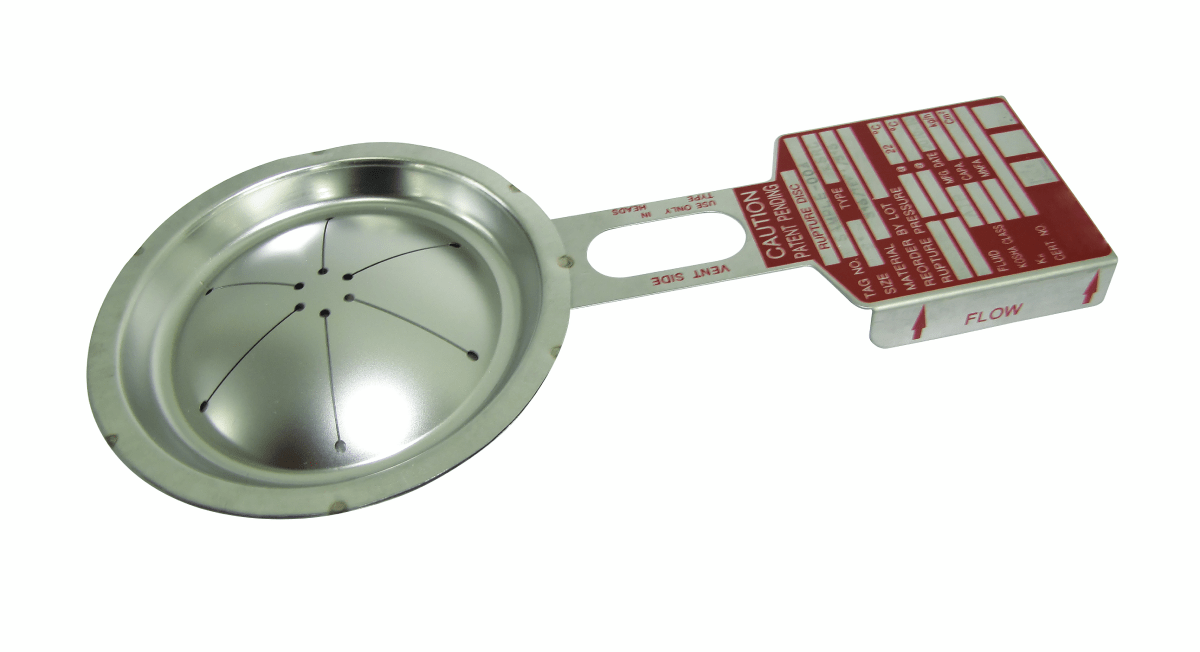

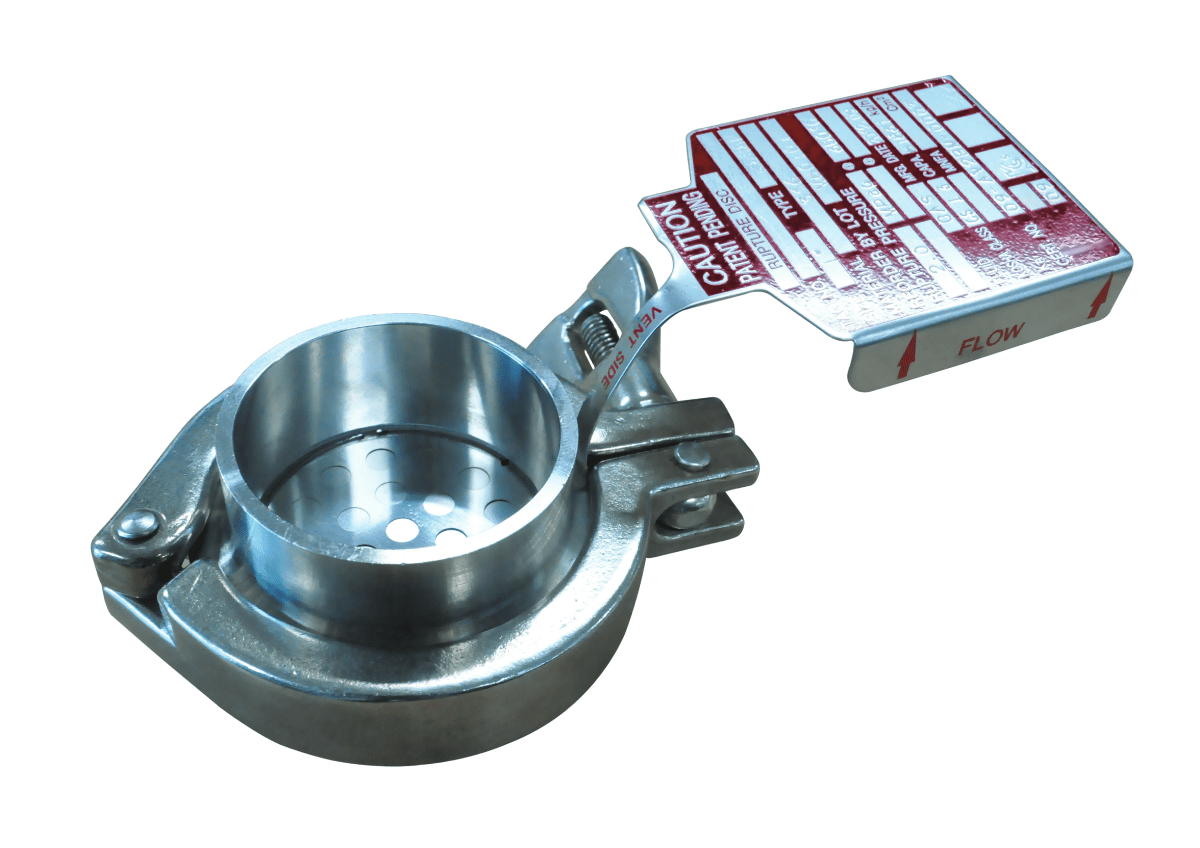

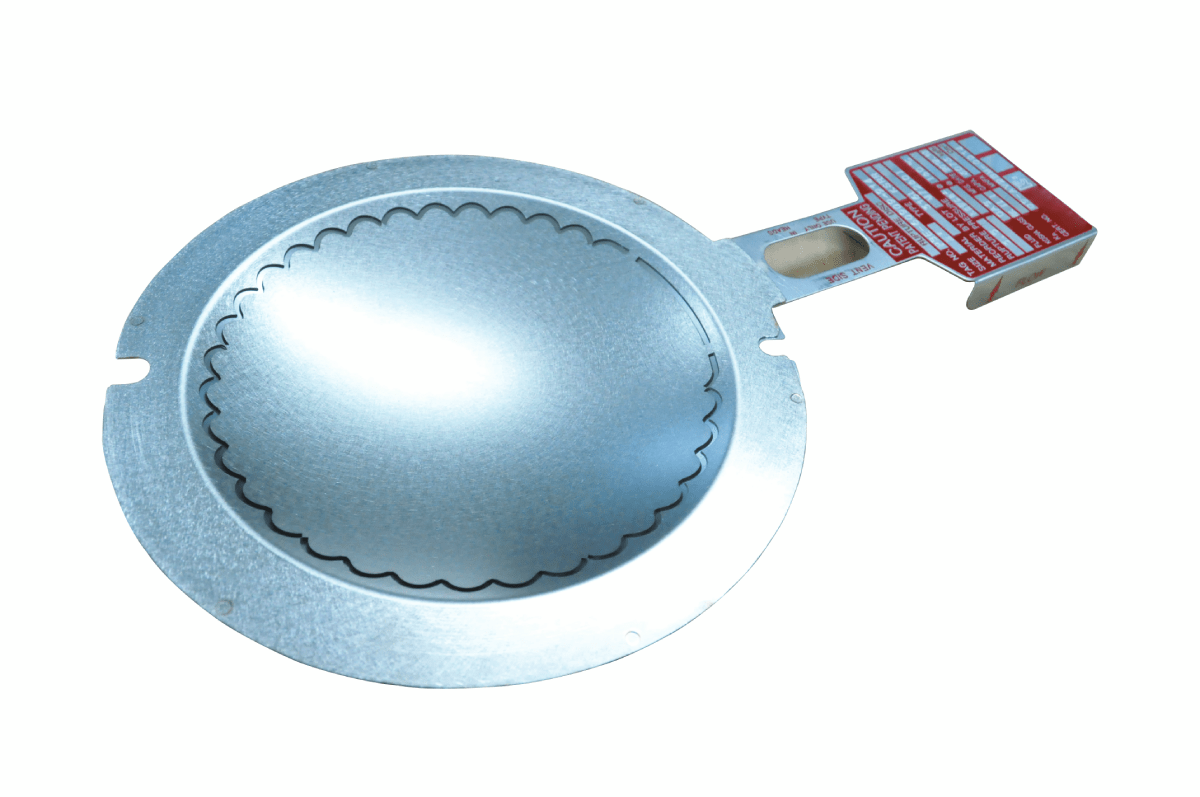

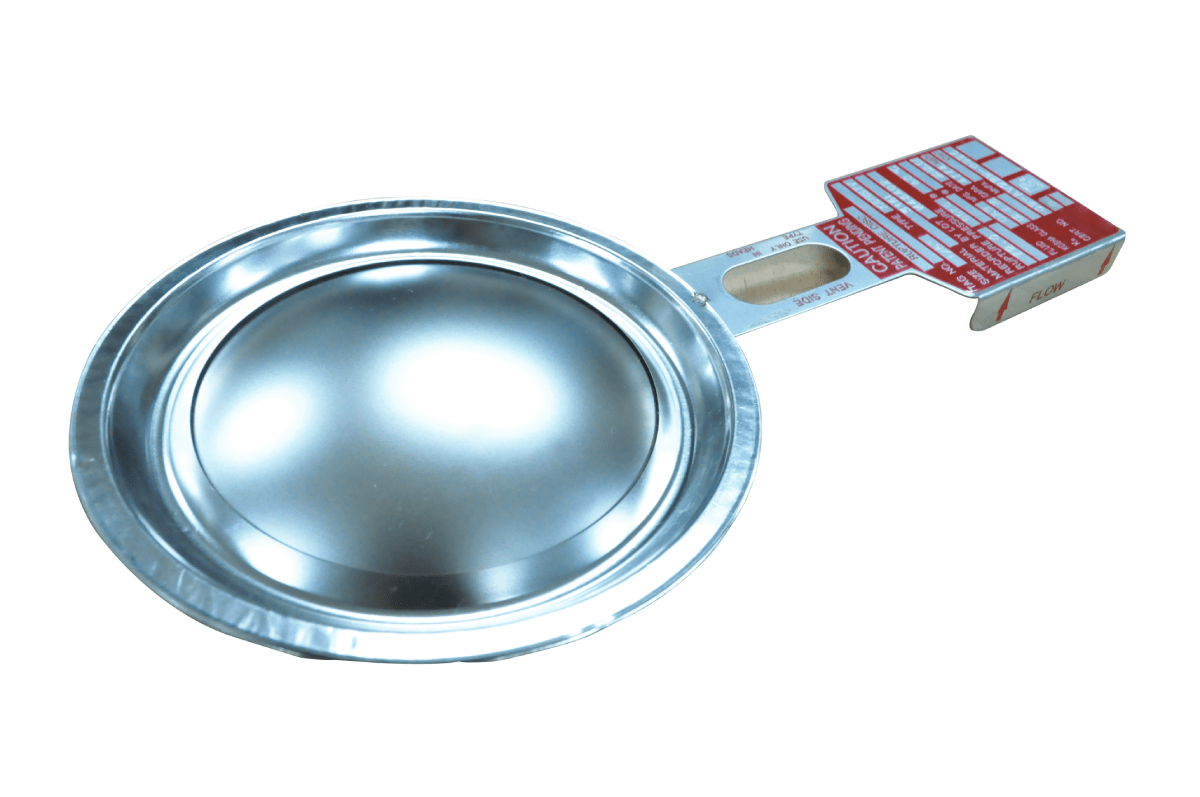

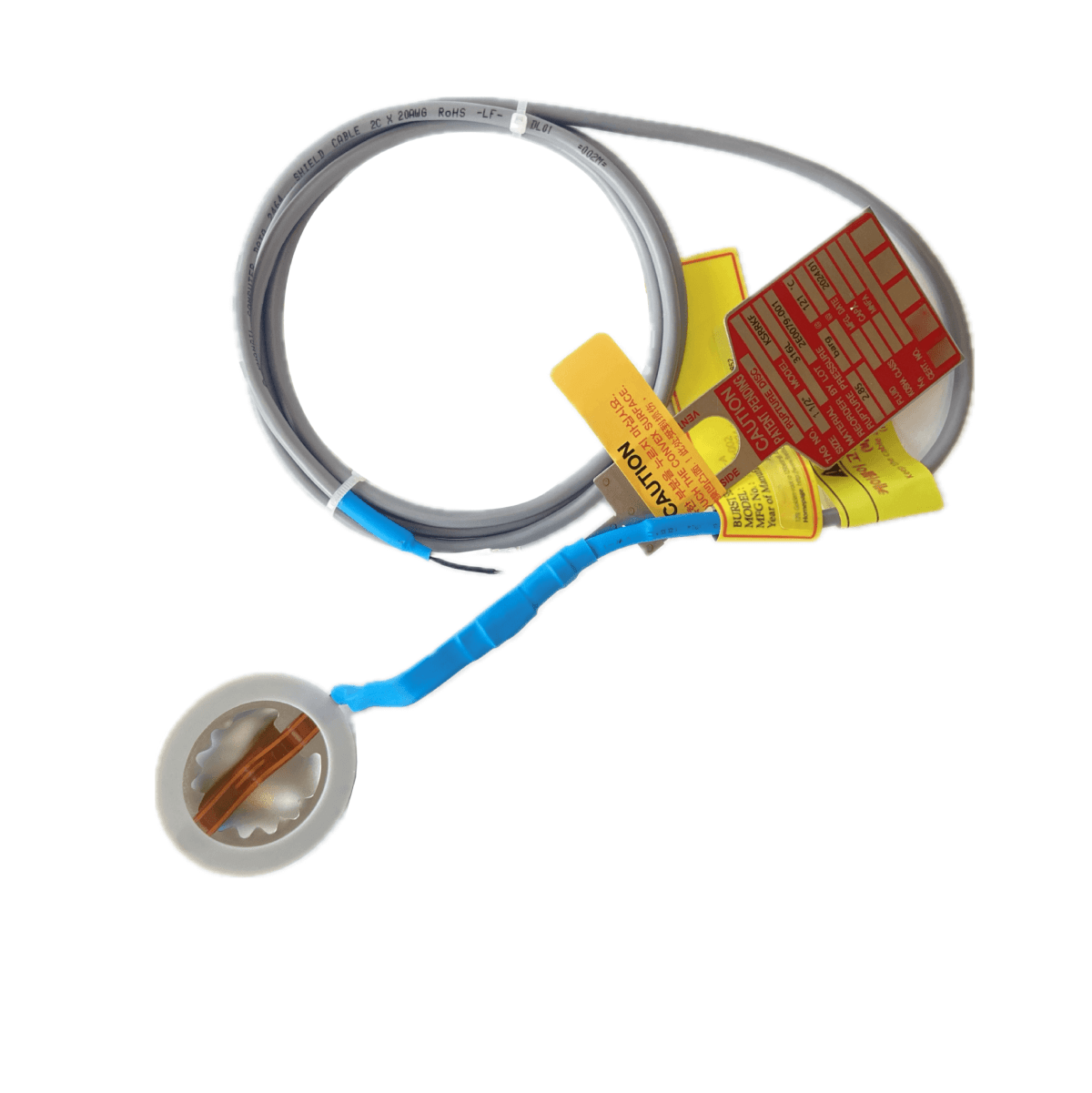

Key Features & Functional Advantages

- Customizable materials and structures — cost-effective with no size limitation

- Accurate burst performance and full release of process media

- Instantaneous discharge of maximum capacity

- Suitable for fluids, gases, vapors, powders, and corrosive environments

- Zero leakage operation

- Prolongs the service life of safety valves when installed upstream

- Allows outlet piping inspection while in operation

- Reduces maintenance costs and extends overhaul intervals

The high quality of rupture discs is suitable for the pharmaceutical and chemical industries for maximum protection against overpressure.

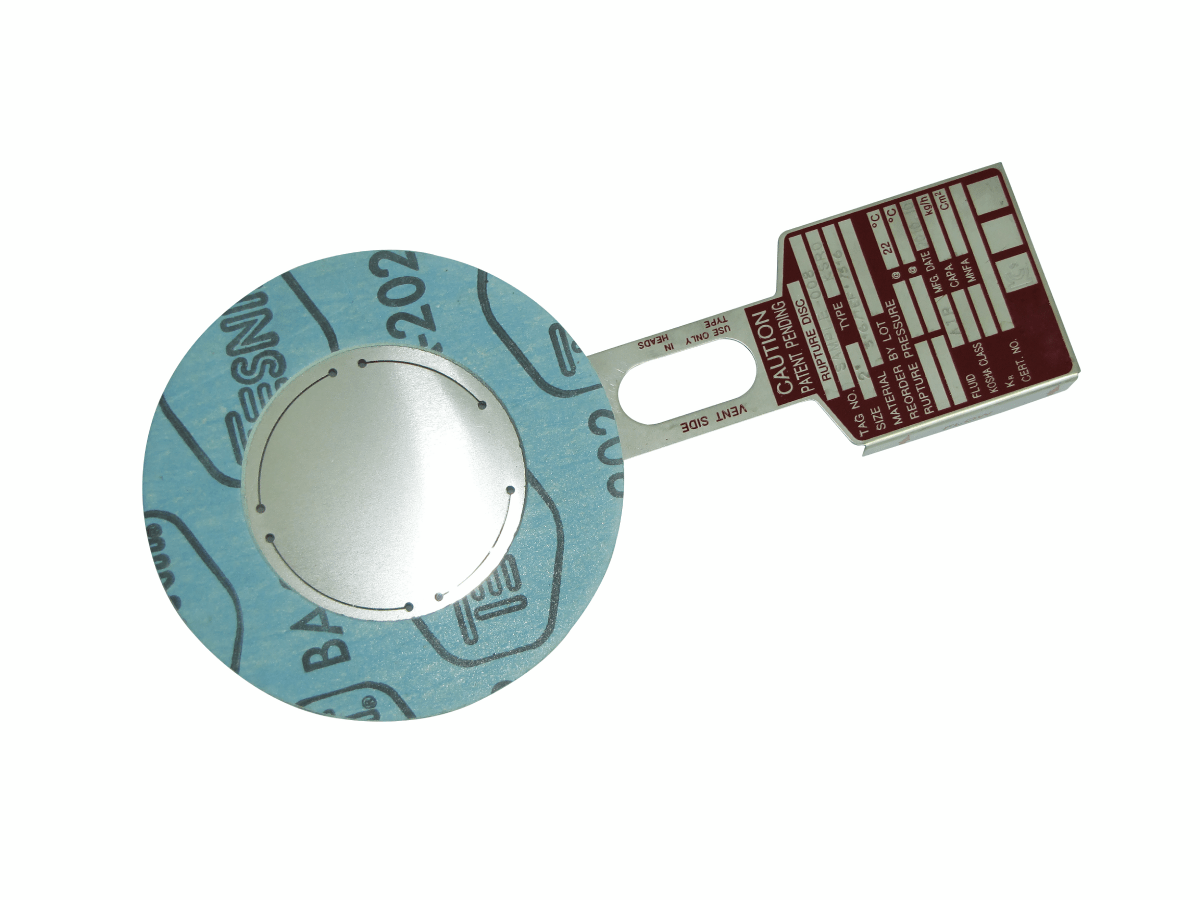

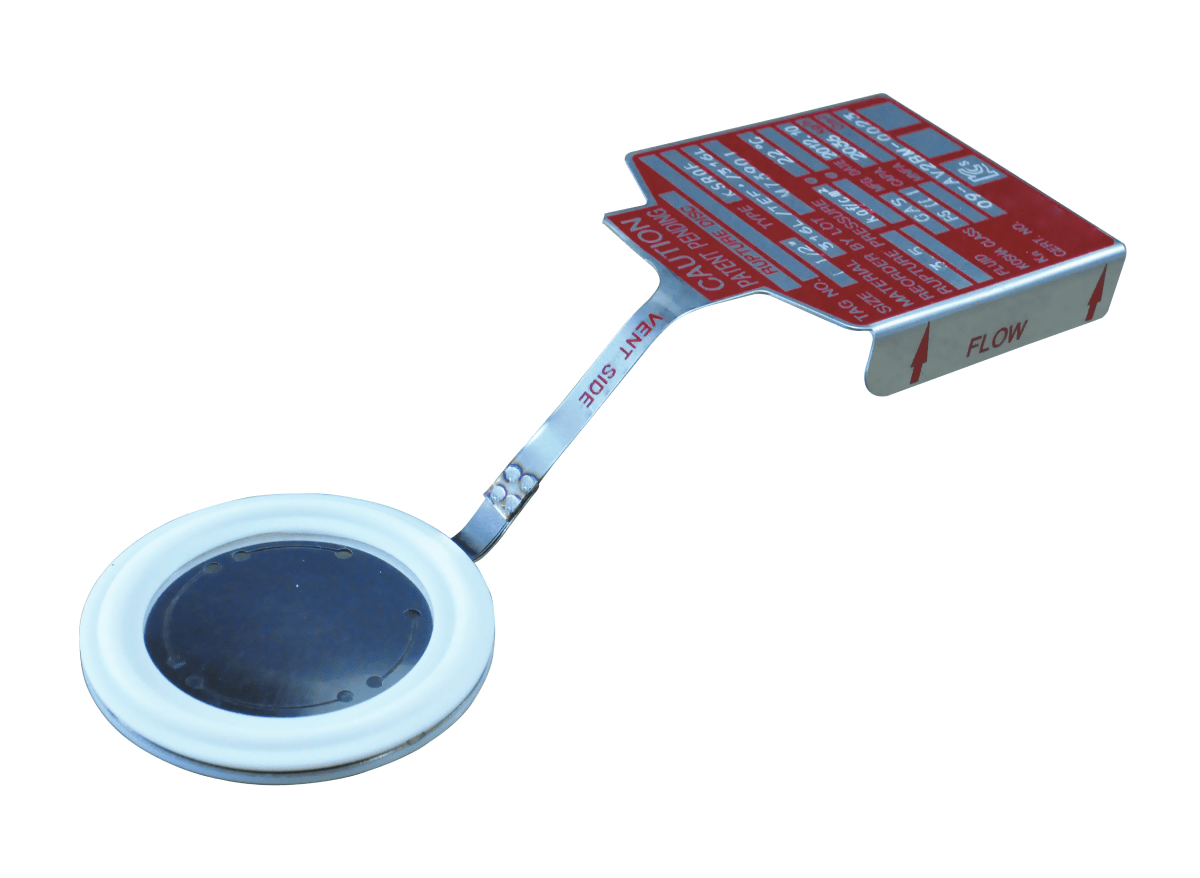

Burst Disc & Holder Materials

FDC bursting discs can be manufactured using a wide range of materials to meet process and corrosion requirements:

- Stainless Steel (304SS, 316SS, 317SS)

- Carbon Steel, Duplex, Aluminum

- Nickel, Inconel, Monel, Hastelloy, Titanium, Tantalium

- Graphite and Teflon (PTFE)

Applicable International Standards

- ASME Sec. VIII Div.1

- ISO 6718, ISO 4126-2 to 4126-6

- API RP 520

- KOSHA Safety Certification