Introduction

Modern industrial processes involving the handling and storage of explosive substances require reliable overpressure protection systems. In the event of an explosion, rapid and effective pressure reduction within the equipment is critical to minimize damage. One of the most effective and common ways to accomplish this is through the use of rupture discs – specially designed safety devices that are triggered in the event of an accident. In this article we will look at how rupture discs work, the different types of rupture discs used for explosion protection, and discuss the key factors that affect their effectiveness and reliability.

What are rupture discs?

Rupture disc (also called a safety disc or diaphragm fuse) is a non-returnable pressure relief device designed to protect equipment, vessels, and piping from overpressure or vacuum. It represents a membrane, usually metal, but can be made of other materials, which is installed in a special holder and is designed to collapse at a certain pressure. At the moment of rupture, the disc forms a fully open cross-section, providing maximum force relief.

The main purpose of these devices is protection. They perform the following functions:

- Equipment collapse prevention: Protect equipment from damage caused by overpressurization.

- Personnel protection: Prevent injury and loss of life associated with explosions and releases of hazardous substances.

- Leak Prevention: In some cases, prevent uncontrolled leaks of toxic or explosive substances.

- Process Safety: Help maintain safe process operation.

- Safety Valve Protection: A rupture disc installed upstream of a safety valve can protect the valve from the corrosive effects of process media and leakage, thereby extending its life and ensuring reliable operation when needed.

Rupture discs are widely used in various industries where there is a risk of overpressure or vacuum:

|

Chemical industry |

Oil and gas industry |

|

Protection of reactors, tanks, distillation columns, etc. |

Protection of pipelines, oil and gas storage tanks, compressors, etc. |

|

Pharmaceutical industry |

Food industry |

|

Protection of sterile equipment, reactors and other processes requiring strict pressure control. |

Protection of equipment for beverages, dairy products, canned foods, etc. |

In addition to these industrial applications, such safety devices are also widely used in the energy, explosives, compressed gases and aerospace industries.

How bursting discs work?

Let's consider the work of rupture disks on the example of pharmaceutical process, where sterility and safety are especially important. Autoclaves are widely used in the pharmaceutical industry to sterilize equipment, materials and media. To kill microorganisms, high temperature and pressure are created in the apparatus. If the pressure control system fails, the pressure can increase uncontrollably, leading to the risk of equipment damage, high temperature vapor release and danger to personnel.

The stages of operation of the rupture disk in the autoclave:

- The rupture disk is mounted on the autoclave body and seals the opening. It is designed to withstand normal pressure fluctuations that occur during sterilization cycles.

- In the event of a malfunction of the pressure control system (e.g., failure of the relief valve or failure of the pressure sensor), the pressure begins to rise above the set operating range.

- When the autoclave pressure reaches or exceeds the preset burst pressure of the disk, the disk instantly ruptures along the preset burst lines, forming a wide open channel.

- Instantaneous disk rupture allows high-pressure medium to immediately exit the autoclave to a safe location (usually a designated discharge line). The rupture disk prevents a catastrophic explosion of the autoclave.

- After the rupture disk actuation the autoclave must be stopped and inspected. The rupture disk must be replaced with a new one certified for this autoclave.

Benefits of bursting discs

Safety discs, as overpressure protection devices, offer a number of significant advantages over other technologies such as safety valves. Here are the main ones:

- Fast and complete pressure relief. Instantaneous opening at the set pressure ensures high flow capacity, especially important in explosions.

- Reliable. Simple design with no moving parts.

- Tightness. 100% leak tightness prior to actuation prevents leakage of the process medium.

- Corrosion resistance. Choice of disc materials for corrosive media.

- Lower cost. Cheaper than safety valves (in most cases).

- Ease of installation and maintenance.

- Safety valve protection. Increased valve life when used together.

- Wide range of pressures and temperatures.

- Self-contained. Do not require an external power source for actuation, ensuring reliability in case of emergency.

Types of rupture discs

In each industry, bursting equipment is selected individually, depending on the specific operating conditions, type of working environment and safety requirements.

According to the mechanism of action there are 3 types of dics:

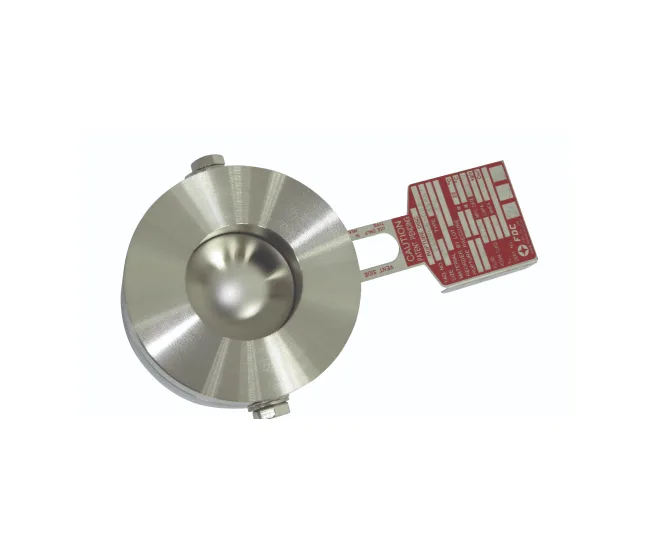

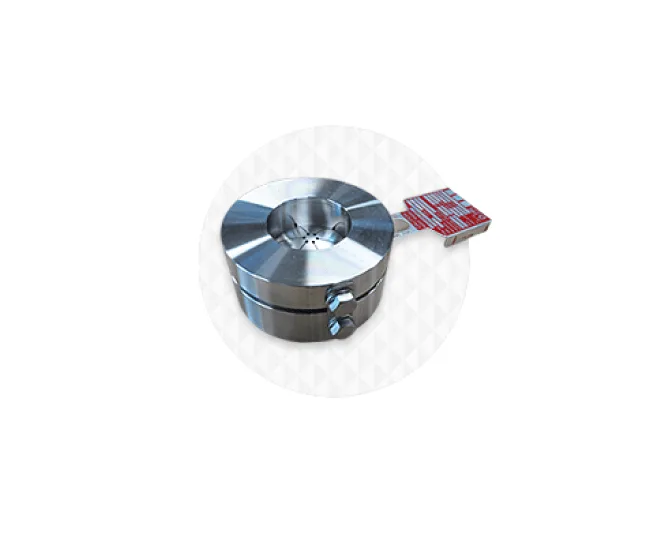

- Forward-acting. Torn by pressure applied to the convex side of the disc.

KSRST - Reverse-acting. Burst under pressure on the concave side of the disc, often requiring a knife.

KSRSR - Double-acting. Designed to relieve pressure in both directions (overpressure and vacuum).

KSRRCHD

In terms of shape, they are distinguished into:

- Domed (have a convex or concave shape)

- Flat (have a flat shape).

According to their construction and material, discs are divided into:

- Solid metal.

- Composite.

- Graphite.

By purpose and specific characteristics they can be:

- Low- and ultra-low pressure.

- Sanitary.

- Fragmenting, non-fragmenting.

- Vent saver, etc.

There are many types of bursting disks available, so you can easily find the right one for your needs.

Conclusion

The rupture disc acts as a safety valve in the event of an explosion, opening instantly upon a sudden increase in pressure to protect the plant and personnel from the devastating effects of an explosion. The correct design and installation of rupture discs is a key element in ensuring the safety of equipment where there is a risk of overpressure or vacuum.