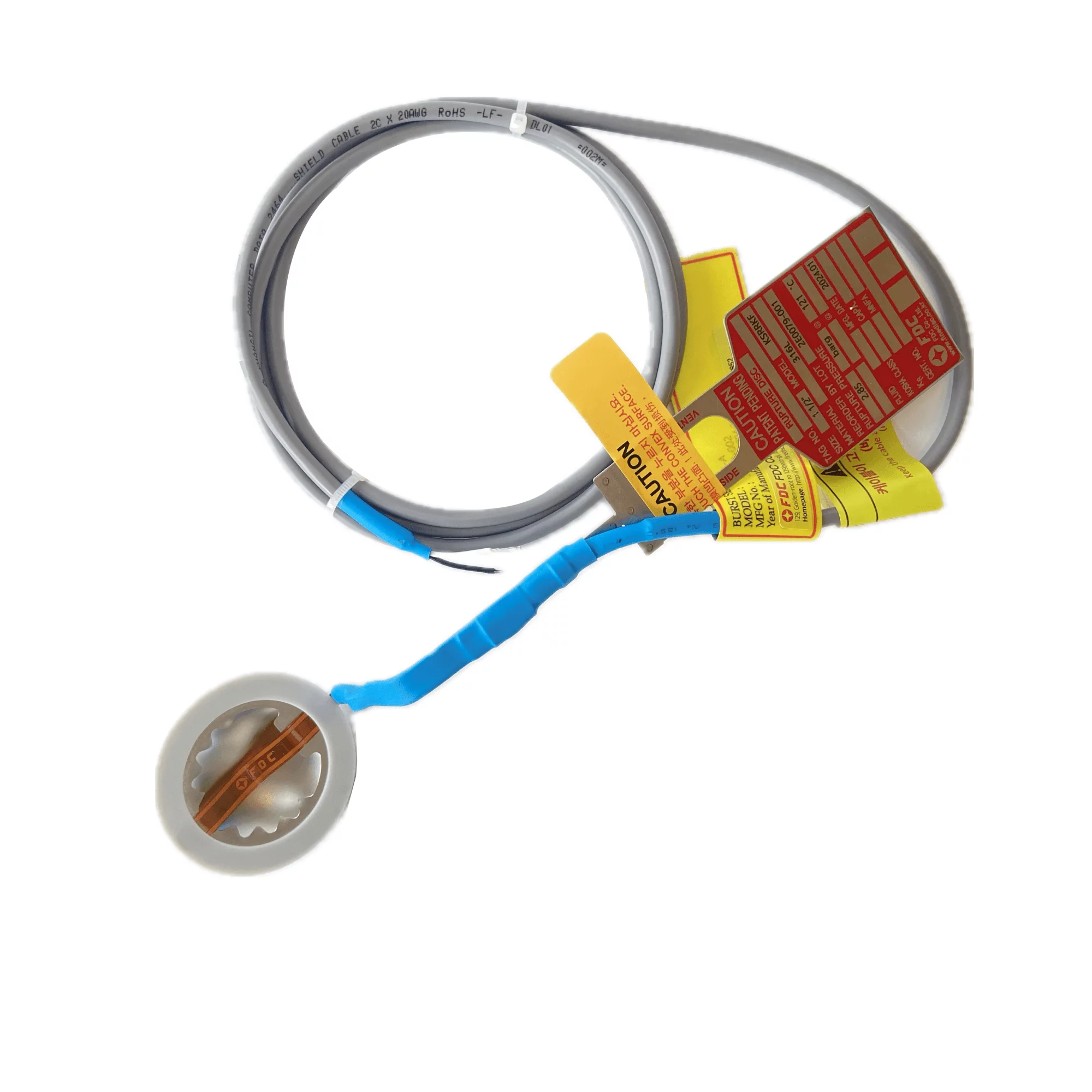

Rupture discs are used when pressure rises rapidly and uncontrollably, when leaks are unacceptable, when there is loss of equipment performance due to disturbing foreign matter, and under unfavourable conditions such as caustic or corrosive fluid, high and low temperatures. The rupture disc is installed on a variety of pressure vessels, pipelines, heat exchangers and furnaces in industrial plants to ensure site safety.

The main purpose of rupture discs is to ensure system safety by controlling pressure. If the set pressure limits are exceeded, the rupture disc automatically ruptures, allowing the excess pressure to be vented and preventing possible emergencies. This is particularly important in production environments where system pressures can vary and are subject to risks of overpressurisation.

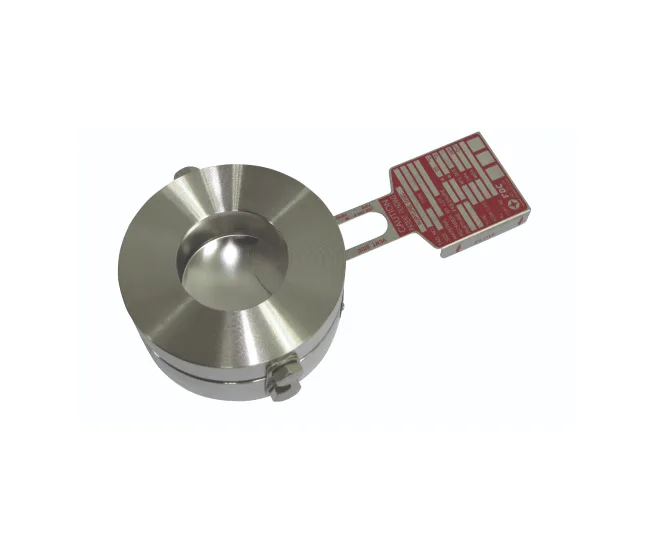

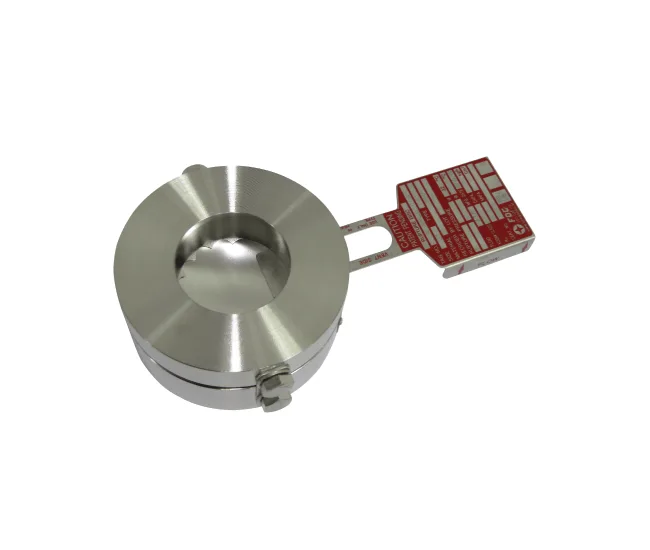

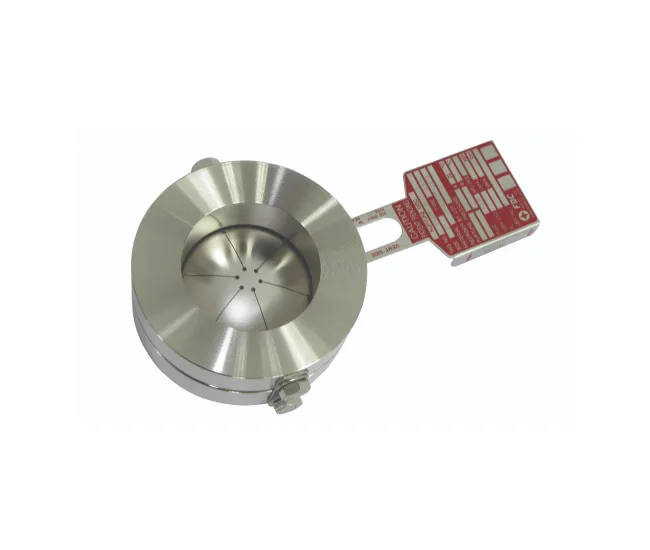

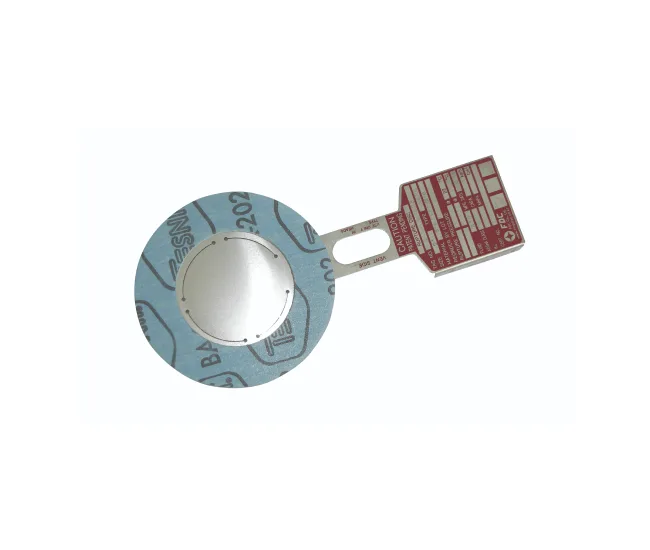

The rupture disc holder locks the rupture disc in position and ensures its reliable operation.

FDC rupture discs prevent even 1% of accidents from occurring. FDC Company Limited and ATEX.CENTER explosion protection centre of expertise are your partners in industrial safety.

Features of FDC rupture discs:

- High Korean quality

- Corrosion resistance

- Vacuum support (if required)

- Easy installation

- Wide range of working temperature

- High reliability

- Sanitary design (if required)

- Suitable for ultra high pressure