Explosion Isolation is a vital component of modern explosion protection strategies, designed to prevent the propagation of flames and pressure waves through ductwork and interconnected process equipment. An Explosion Isolation System works by physically separating the ignition source from the rest of the production line within milliseconds, thereby limiting the scope of the incident and avoiding secondary explosions.

Explosion isolation methods are divided into active and passive technologies:

-

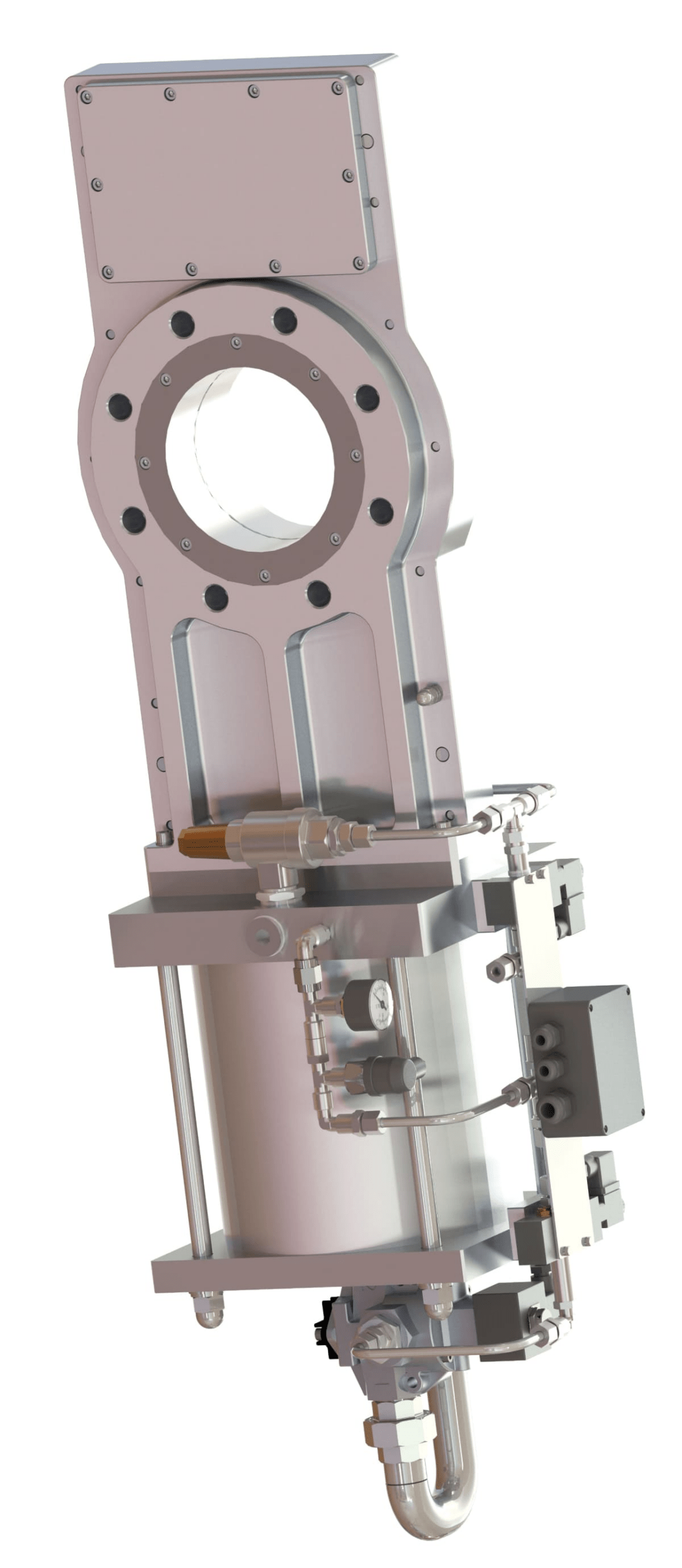

Active isolation relies on rapid detection of pressure rise or flame fronts using sensors. Once a deflagration is detected, the system activates high-speed barriers—such as HRD Chemical Isolation systems — to inject a suppressant agent or instantly close a Quick-acting slide valve. These systems react automatically and with high precision, stopping the explosion before it travels further.

-

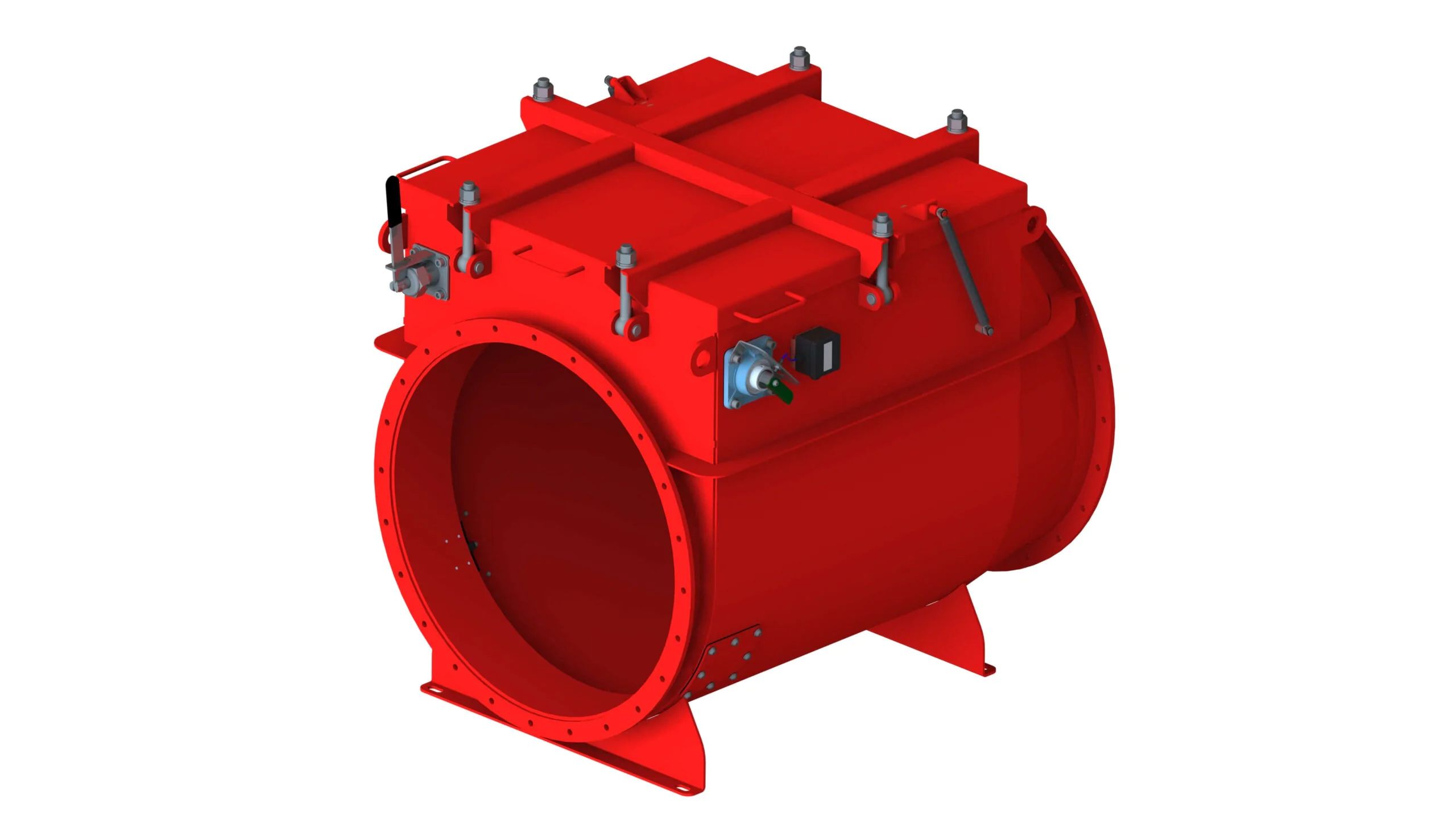

Passive isolation devices include isolation flap valves, which respond mechanically to pressure waves or flow reversal. These valves close upon the arrival of an explosion front, forming a barrier that contains the blast within the affected section.

The need for reliable isolation is clearly outlined in global safety standards like NFPA 69 and EN 1127-1, which emphasize the importance of technical means for halting explosion transmission between process units. Explosion Isolation Systems are especially critical in industries where combustible dust or gas is present—such as food and feed processing, biomass handling, pharmaceuticals, and chemical manufacturing.

From filters and cyclones to silos and pneumatic conveying systems, ATEX.CENTER delivers comprehensive explosion isolation tailored to your process, helping you protect personnel, minimize downtime, and comply with safety regulations. Our equipment is certified under ATEX and other international standards, ensuring high reliability in hazardous environments.