Curious about the mechanics behind dust explosion protection? Let’s delve into the intricacies of safeguarding your operations against the devastating effects of dust explosions with ATEX.CENTER.

Active Defense vs. Passive Defense

In the realm of dust explosion protection, two distinct approaches stand out: active defense and passive defense. While active defense involves proactive measures such as real-time monitoring and suppression, passive defense is a mechanically based protection that works by changing the pressure inside the protected equipment.

Understanding Dust Hazards & Ignition Risks

Dust hazards pose significant ignition risks in industrial settings, making prevention and protection paramount. From combustible dust particles to potential ignition sources, understanding these risks is crucial for implementing effective safety measures.

Discovering the Solutions

Fortunately, a range of solutions exists to address dust explosion risks comprehensively.

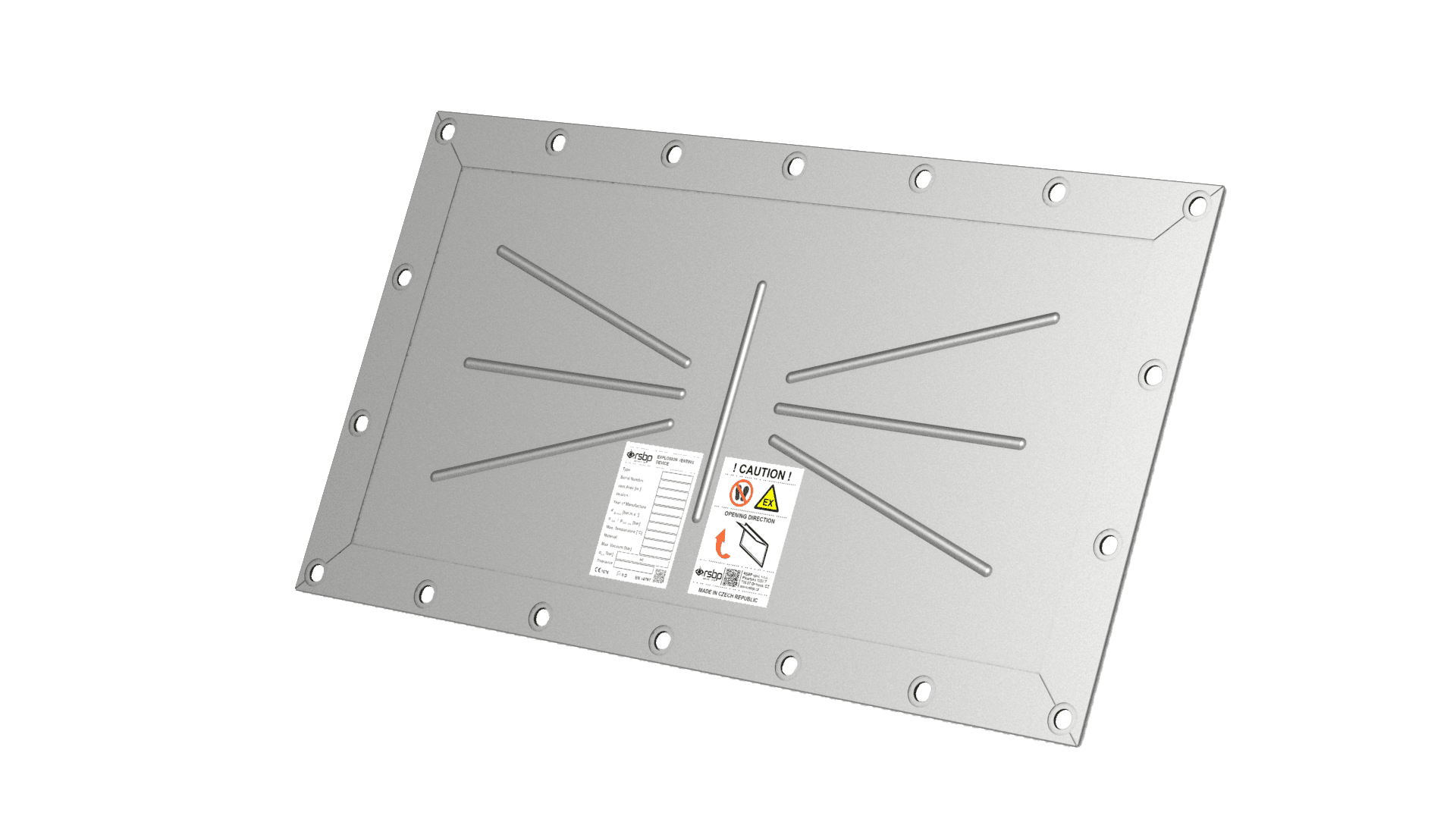

Shielding of containers

Protection of containers against dust explosions is a primary concern. Robust containment systems, coupled with explosion-resistant materials, shield containers from the destructive forces unleashed during explosions.

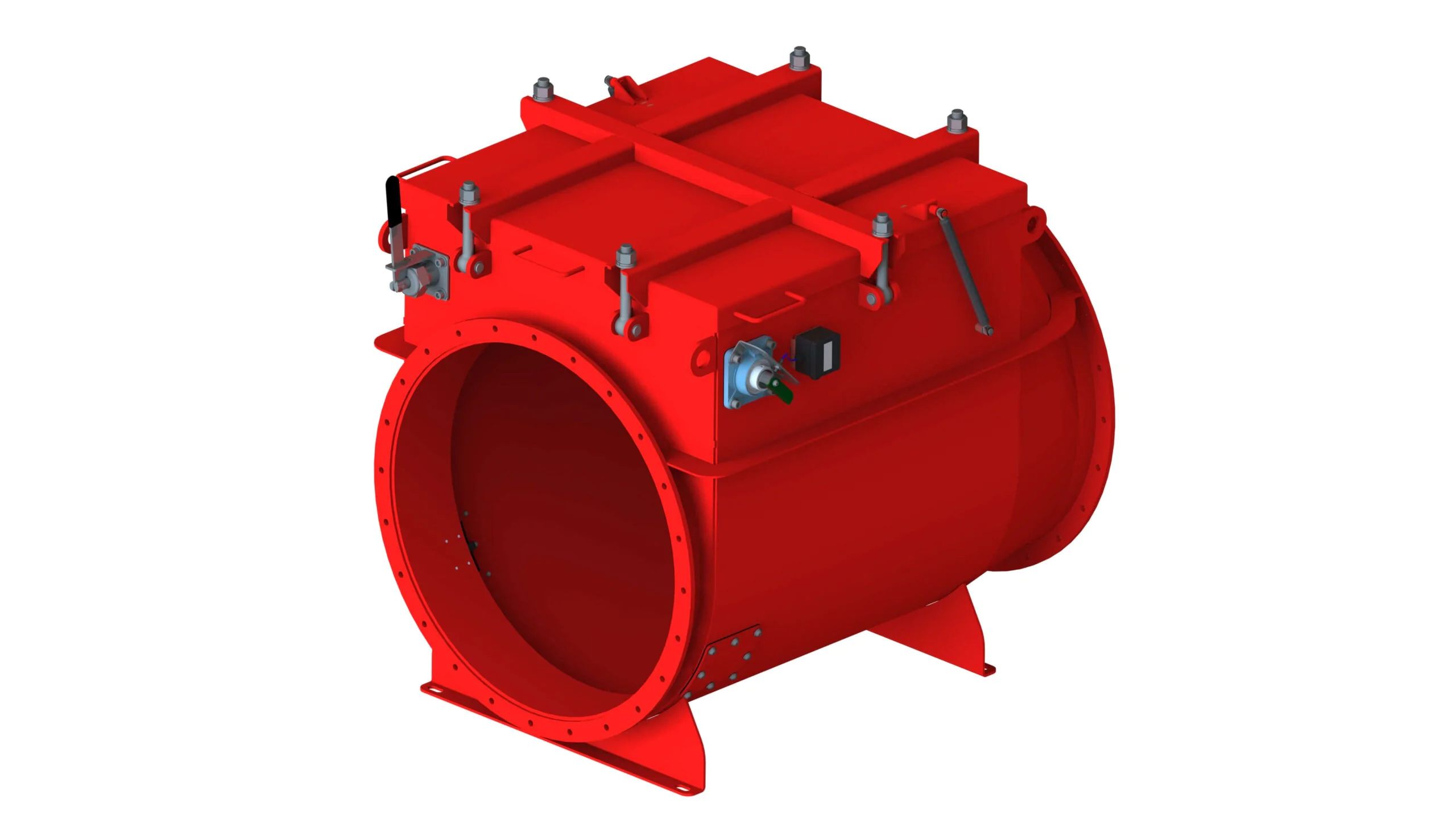

Safeguarding Connected Equipment: Isolation

Isolating connected equipment is vital to prevent cascading damage in the event of a dust explosion. Isolation systems swiftly cut off affected equipment, containing the blast and minimizing collateral damage.

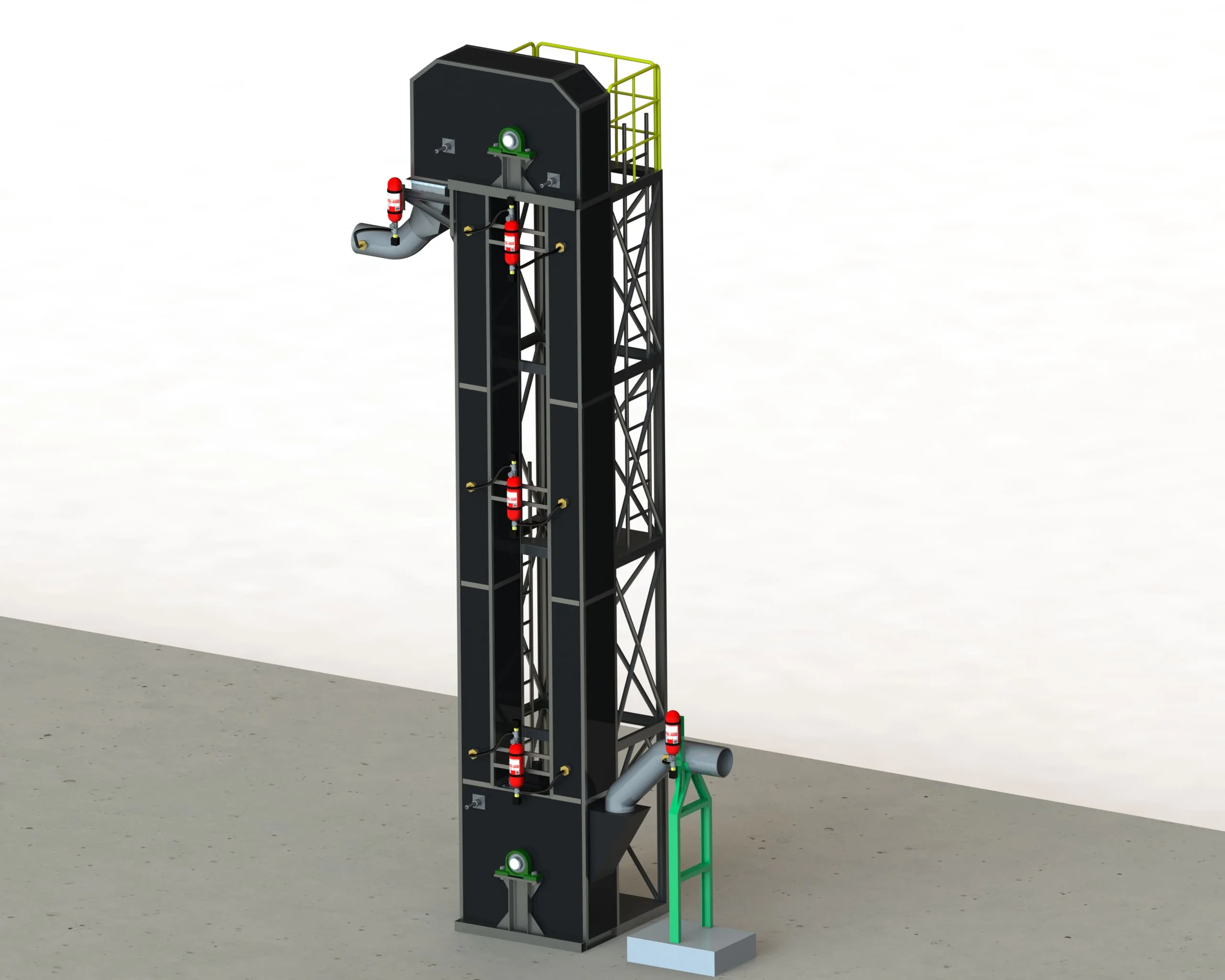

Ensuring Safety: Explosion Suppression

Explosion suppression technology adds an extra layer of safety by swiftly detecting and suppressing explosions. By deploying suppression agents, these systems neutralize explosions before they escalate, safeguarding both equipment and personnel.

Invest in dust collector explosion protection and shield your operations against the dangers of dust explosions with ATEX.CENTER. Our comprehensive solutions for protection against dust explosions encompass advanced technologies and expert guidance, ensuring the safety and continuity of your industrial processes.