All maintenance work must be recorded in a work log. It is included in the scope of supply.

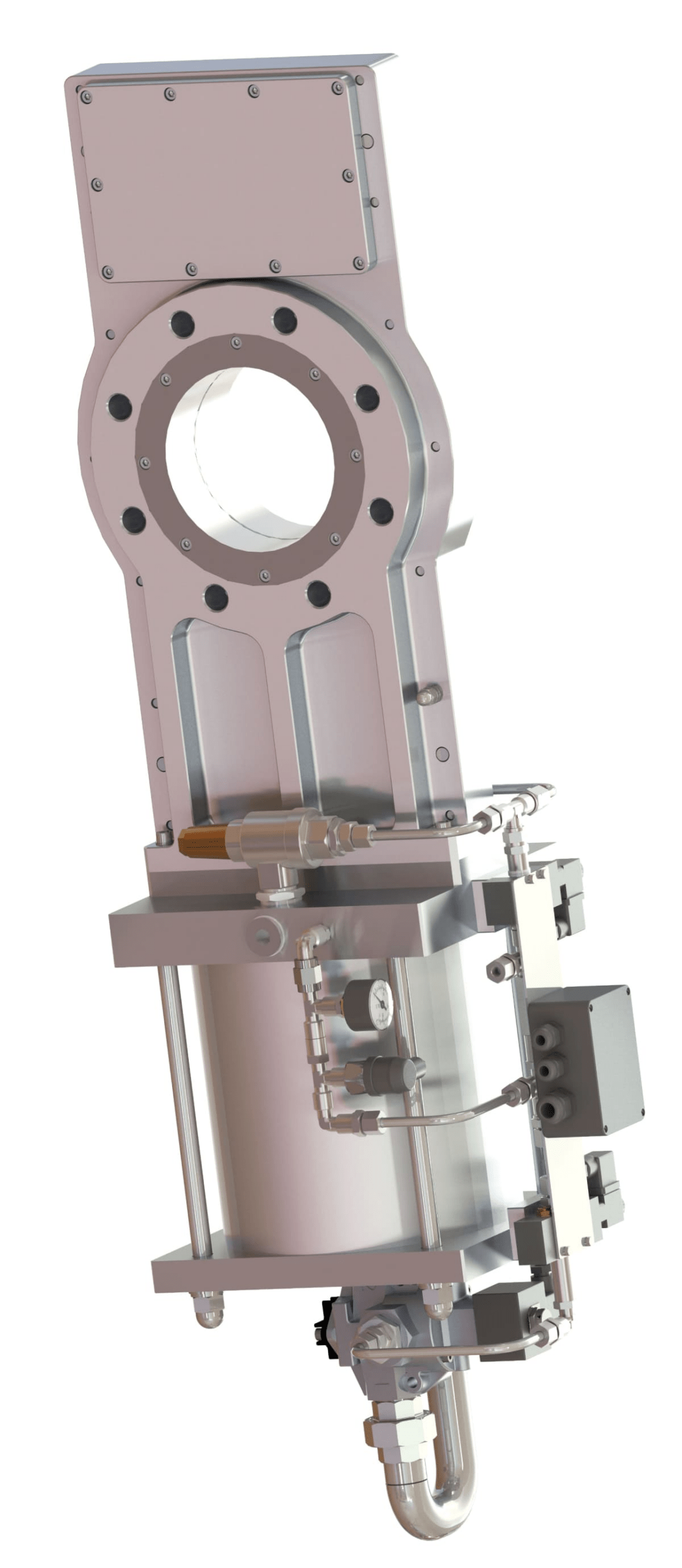

- Mechanical – the valve structure, locking blade and connecting flanges;

- Pneumatic – valves, piping, pressure gauge and silencers;

- Electrical – electrical coils, pneumatic actuator, wiring, sensors.

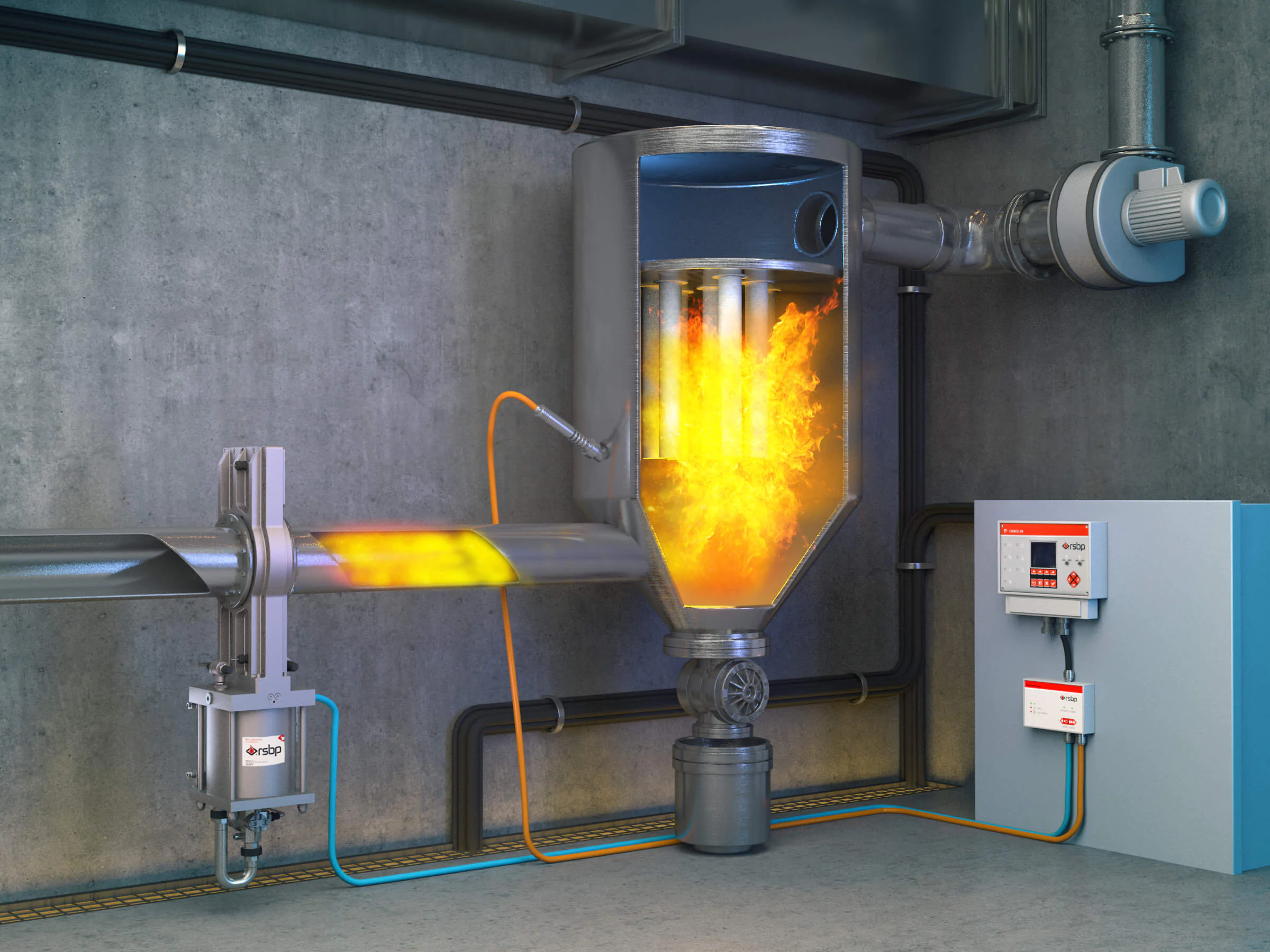

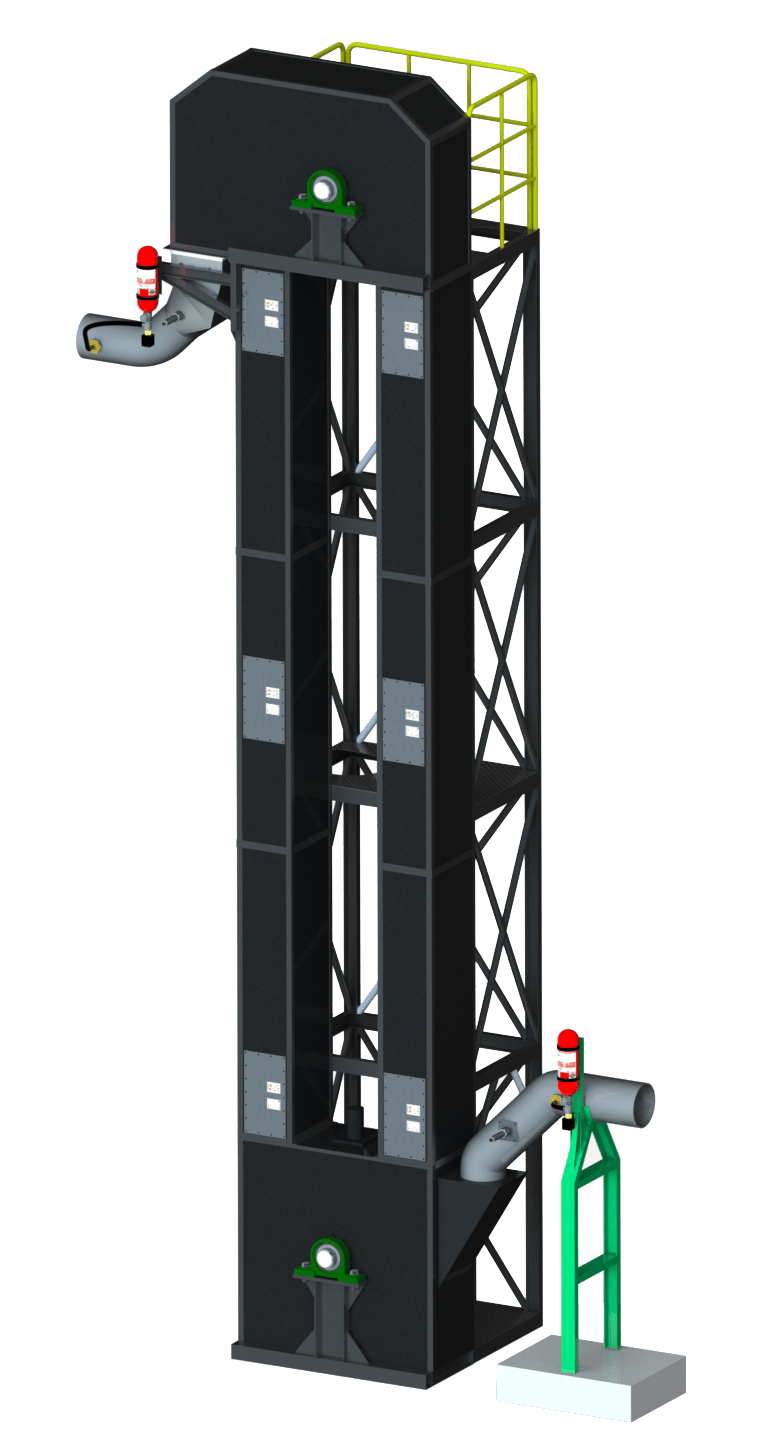

This is a guillotine-type gate valve which operates on the principle of continuously monitoring the pressure of the dust/air mixture in the pipeline to be protected. If an explosion occurs, this parameter rises. The pressure sensors immediately transmit a signal to the CONEX control centre. The controller sends an electrical impulse to the pneumatic actuator, which ensures rapid closure within milliseconds of the hazardous section of the pipeline. The high response speed allows the valve to be installed in the immediate vicinity of explosive equipment.

The GATEX Guillotine Gate Valve is protected against failures. When normal operation is disturbed: pressure in the pneumatic circuit drops below 5 bar, the power supply or control signal is lost, it automatically enters into a slow closing mode and closes the pipeline.

Important. The pneumatically actuated GATEX gate valve may only be used for localisation of an explosion. This device should not be used for shutting off the main substance in a pipeline.

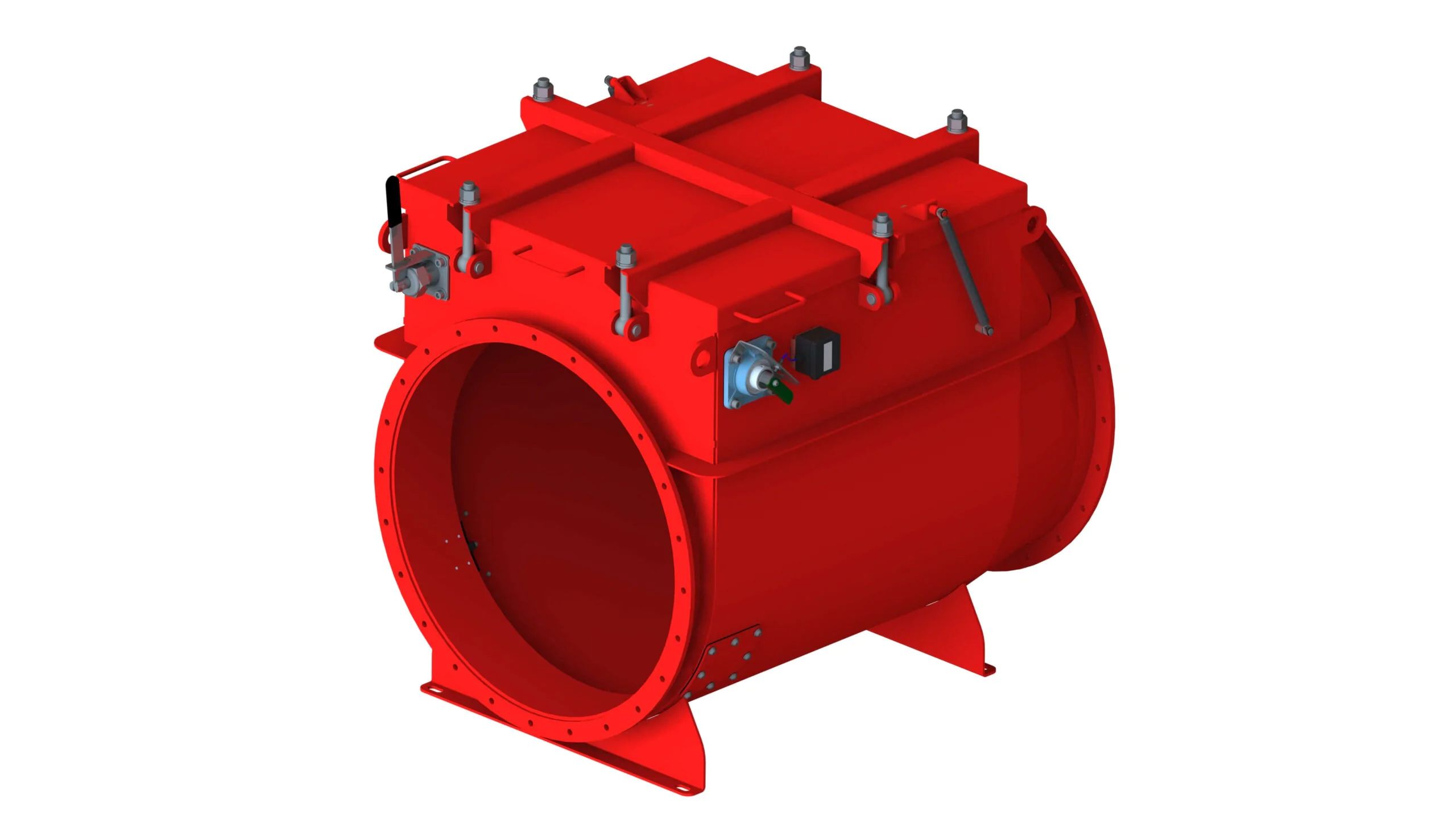

- Provides rapid containment of an explosion – in less than 60 ms.

- Applicable on pipelines with nominal diameters from 50 to 200.

- Resistant to overpressure up to 21 bar.

- Can be operated at ambient temperatures from -5°C to 50°C (with heated casing from -30°C, with other special components up to 70°C).

- Can be installed in close proximity to explosive equipment, thus greatly reducing the potential area of destruction in an explosion.