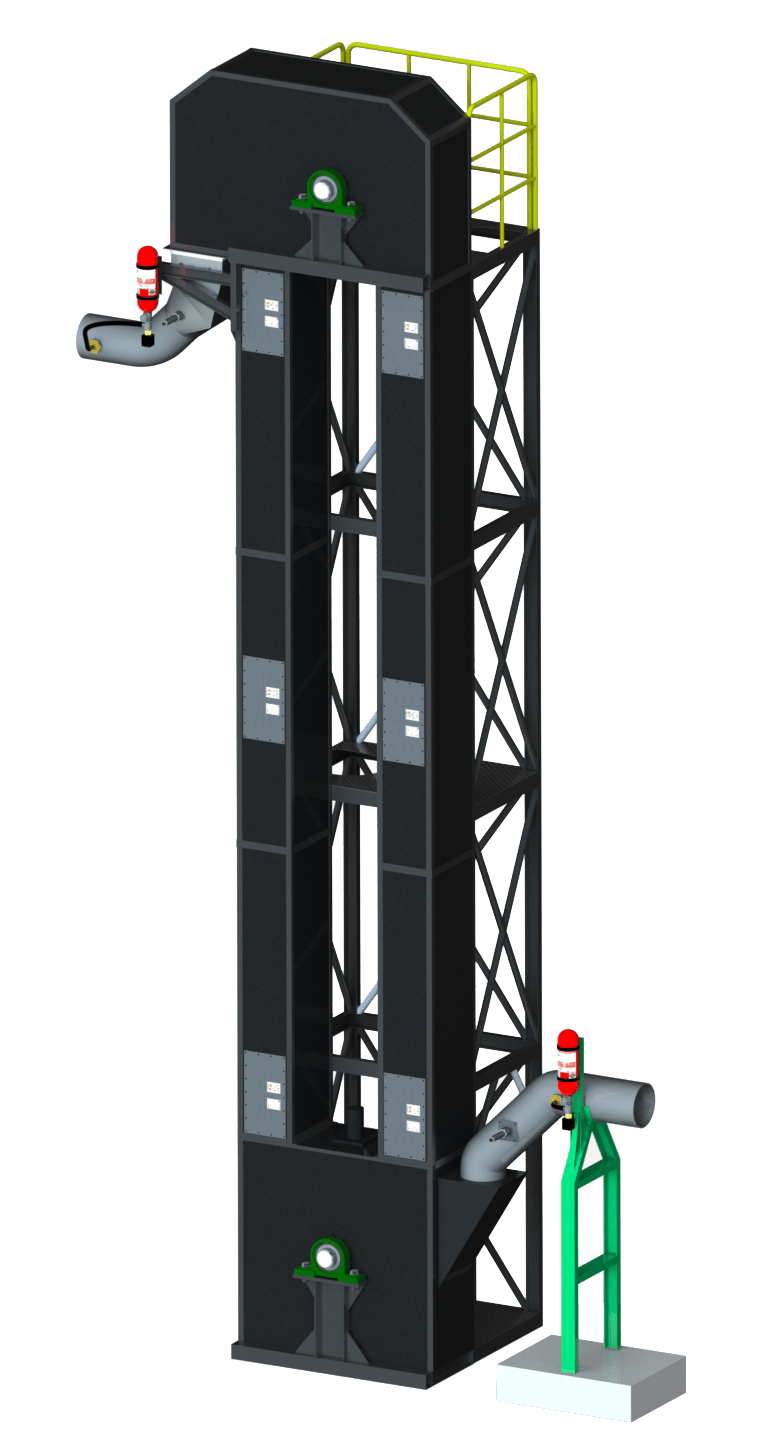

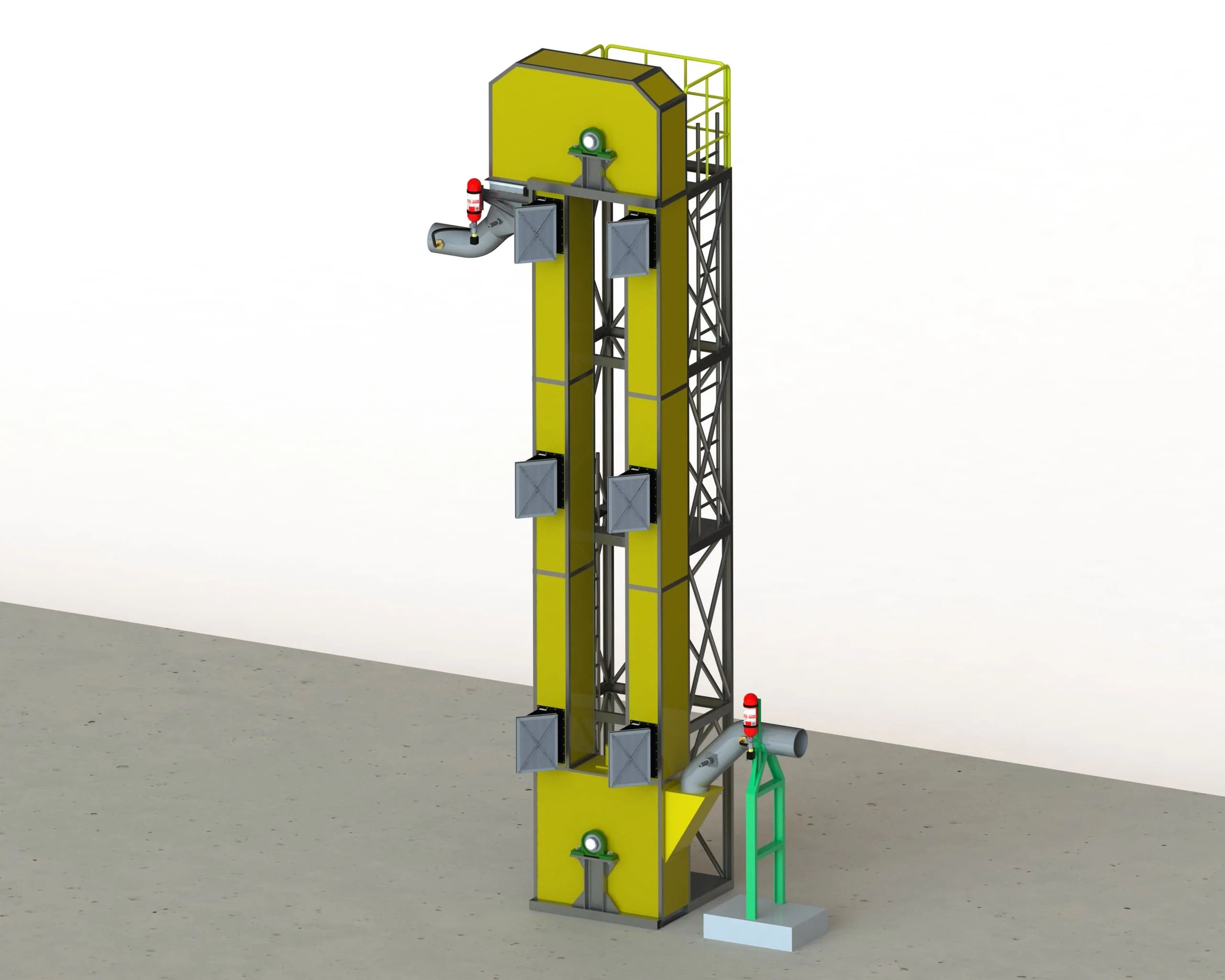

The peculiarity of the passive protection of ELEVEX elevators based on explosion release is that it can only be used in open areas or with the installation of explosion venting ducts. Shockwaves and flames can damage equipment in the vicinity and endanger lives. Explosion-proof doors and membranes are therefore not used in the vicinity of personnel working areas.

However, it is the most economical way of providing explosion protection because its elements are inexpensive as compared to other devices, easy to maintain and easy to replace once triggered.

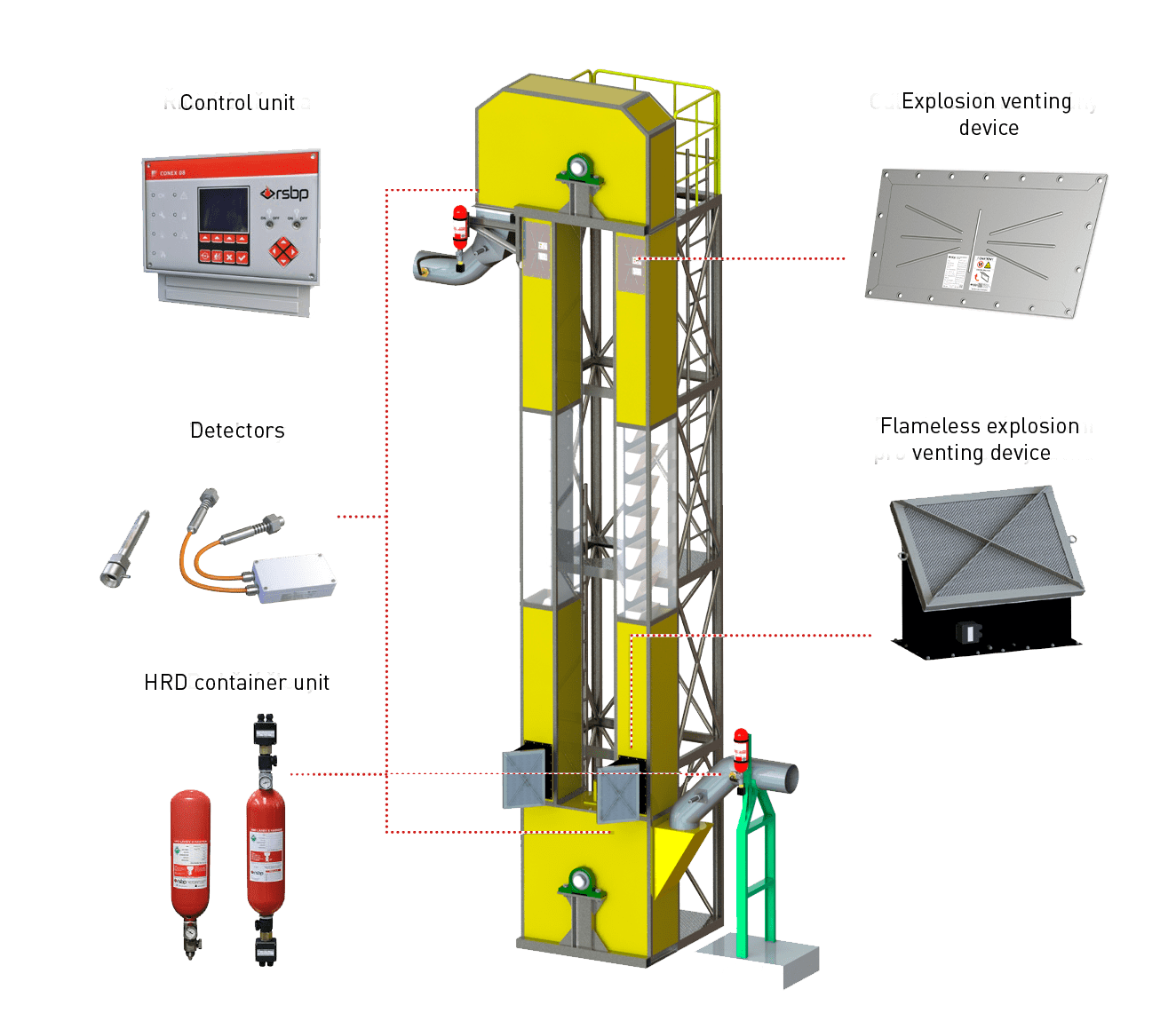

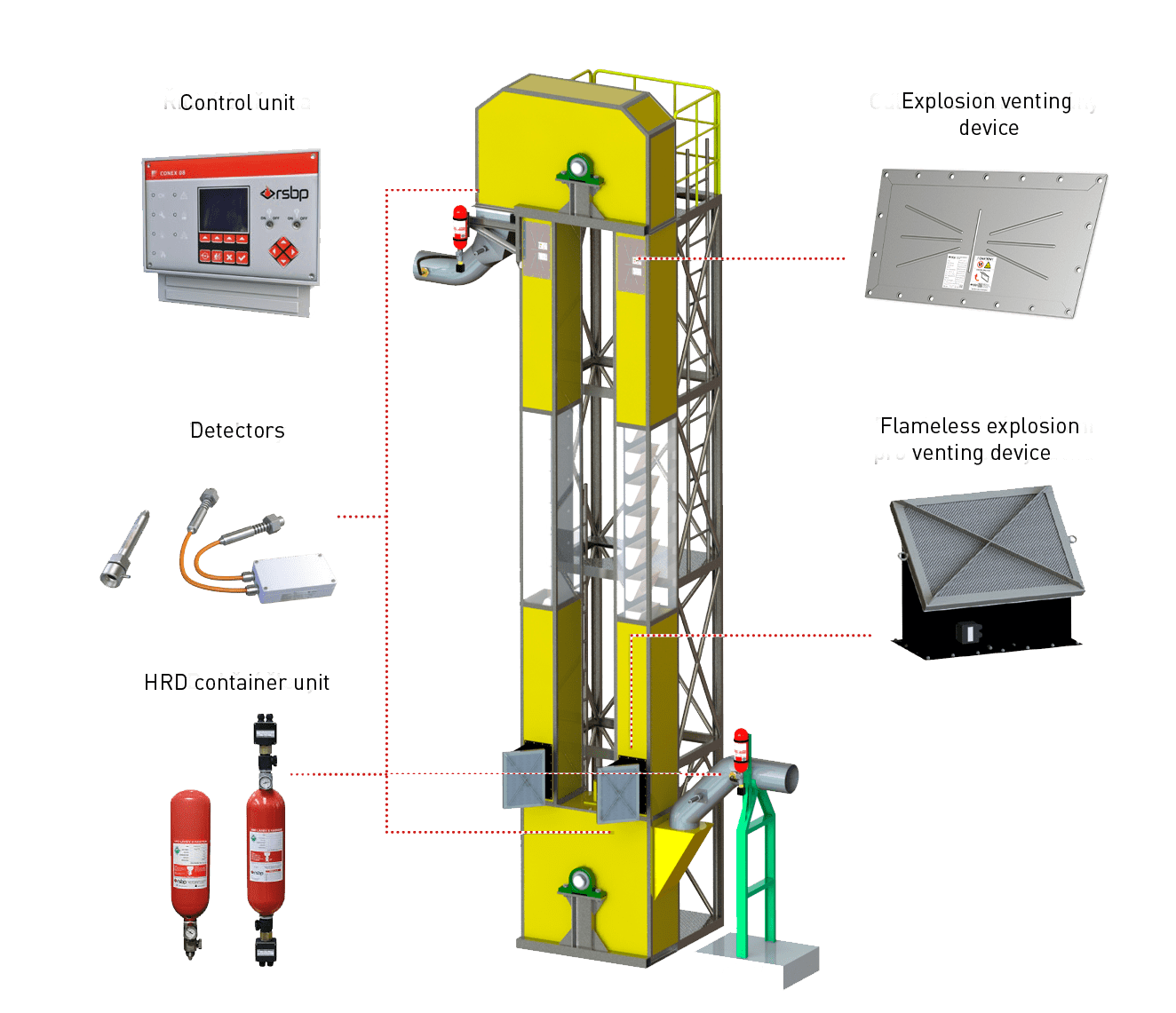

The ELEVEX explosion detection system consists of three components:

- explosion sensors;

- explosion containment devices on the inlet and outlet piping;

- explosion panels on the elevator housing.

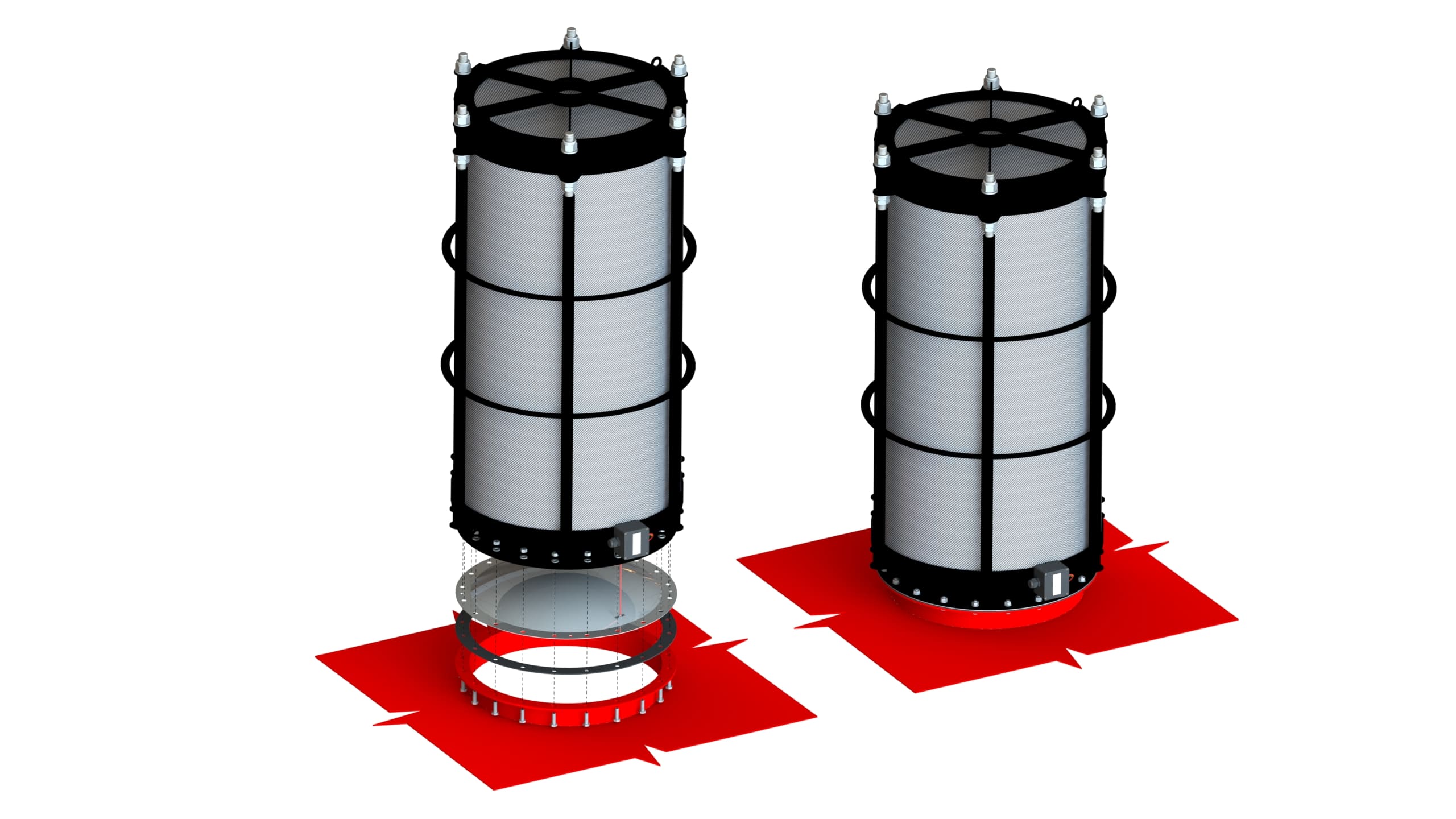

VMP explosive membranes are available in round or rectangular stainless steel. They are additionally equipped with flange seals to ensure dust-tightness of the device; cable or magnetic indicators for opening/closing; thermal insulation to prevent condensation.

- Five types for different operating conditions, with a temperature range of up to 240 °C. Available in models resistant to overpressure or pressure surges.

- The large range of sizes enables a suitable rupture disc to be selected for most types of process equipment.

- The membrans are made of steel and are resistant to mechanical damage.

- Easy to assemble – installation consists of only two steps, according to ready-made drawing kits and assembly instructions.

- Easy to maintain – we will provide a detailed instruction manual describing the frequency of all operations. The customer’s employees are only required to visually inspect the cleanliness and integrity of the blast panel.

- Simply replace after an accident. Can be installed without altering the design of the existing process equipment.

- Maintenance is only required once a year, which reduces the cost of operation.