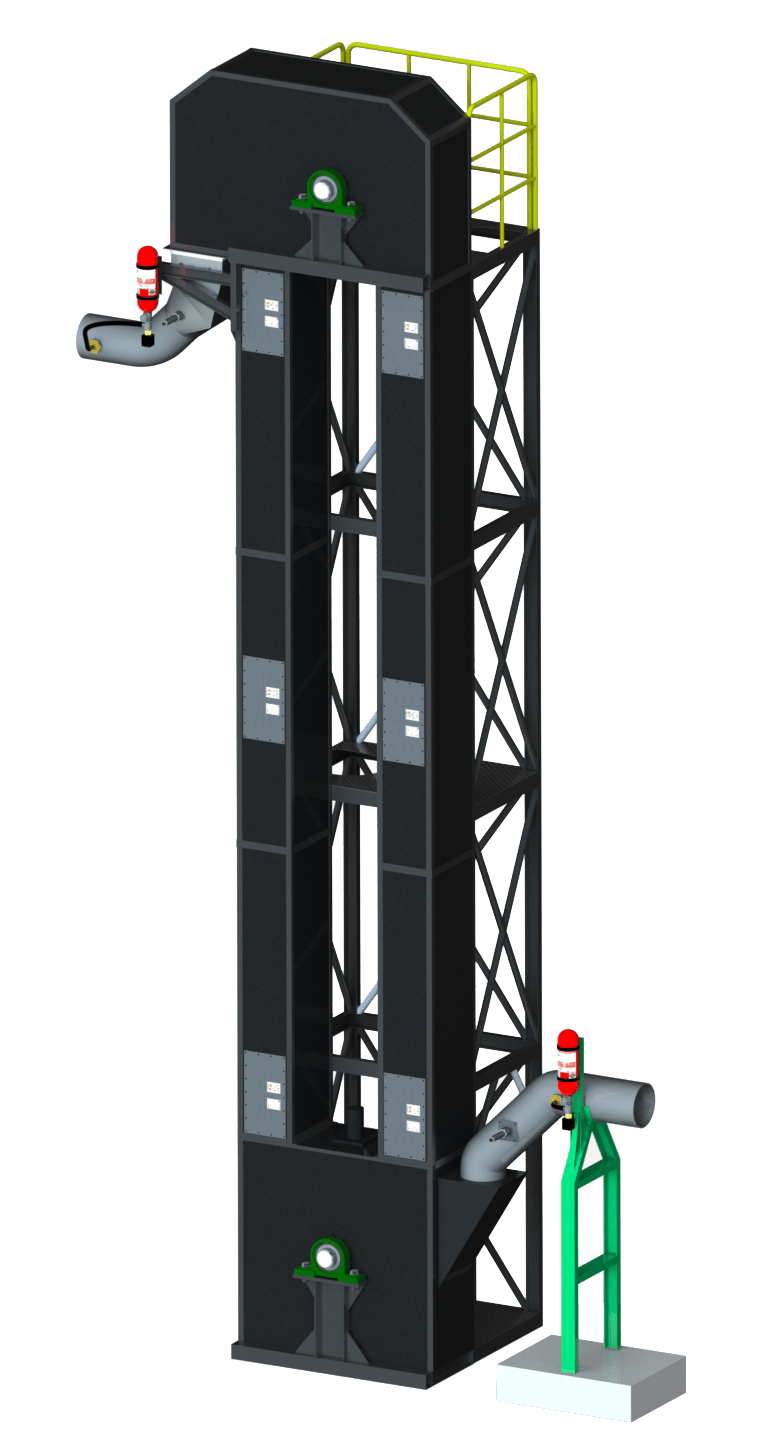

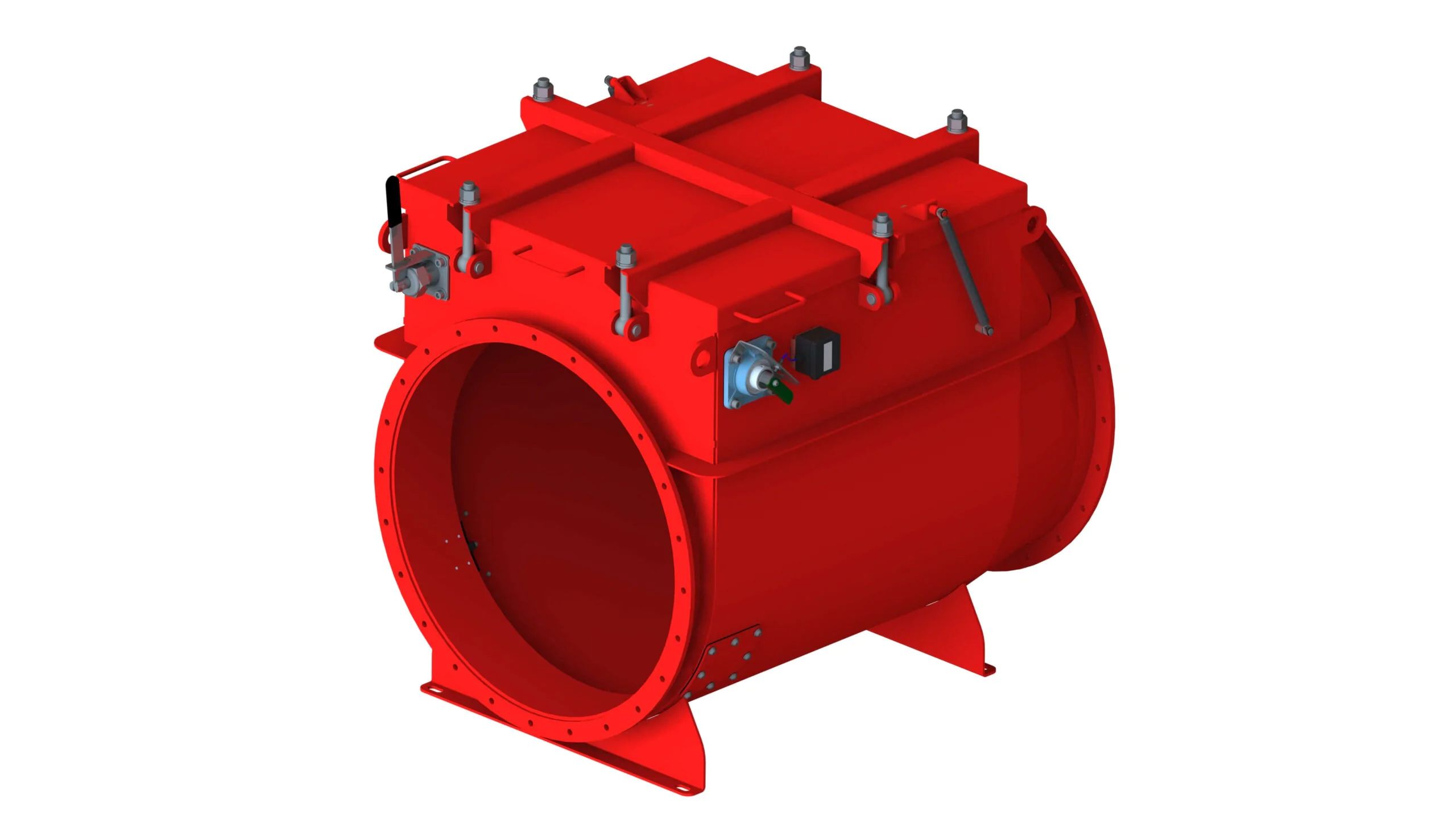

Like the HRD system, it is designed for active suppression of an explosion at its incipient stage. WATER SHOT cylinder is used where explosive suppressant powder cannot be used. Primarily in the food industry, where the extinguishing agent clogs equipment and damages the purity of finished products.

The principle of construction and operation is similar to the HRD system. Pressure transducers or optical sensors detect the onset of an explosion and transmit the information to the control centre – the CONEX controller. This processes the signal and triggers the water cylinders. As a result, the pressure and temperature of the dust/air mixture is reduced to safe levels. The entire process takes no more than 60 ms.

- Does not contaminate equipment with extinguishing powder. Can be used in the food and pharmaceutical industries where strict hygiene requirements exist.

- Suppresses explosions quickly – no more than 60 ms elapses between detection and application of the suppressant. No explosion products leave the premises.

- Easy to assemble – it takes only two steps to assemble, using ready-made blueprint kits and assembly instructions.

- Easy to maintain – we will provide a detailed instruction manual, outlining the frequency of all operations. The customer’s employees only have to visually check that the components are clean and undamaged and check the cylinder pressure monthly.

- It is installed without changing the design of the existing technological equipment.

- Can be used in open areas and in confined spaces.

- The active elements can be easily replaced after use.