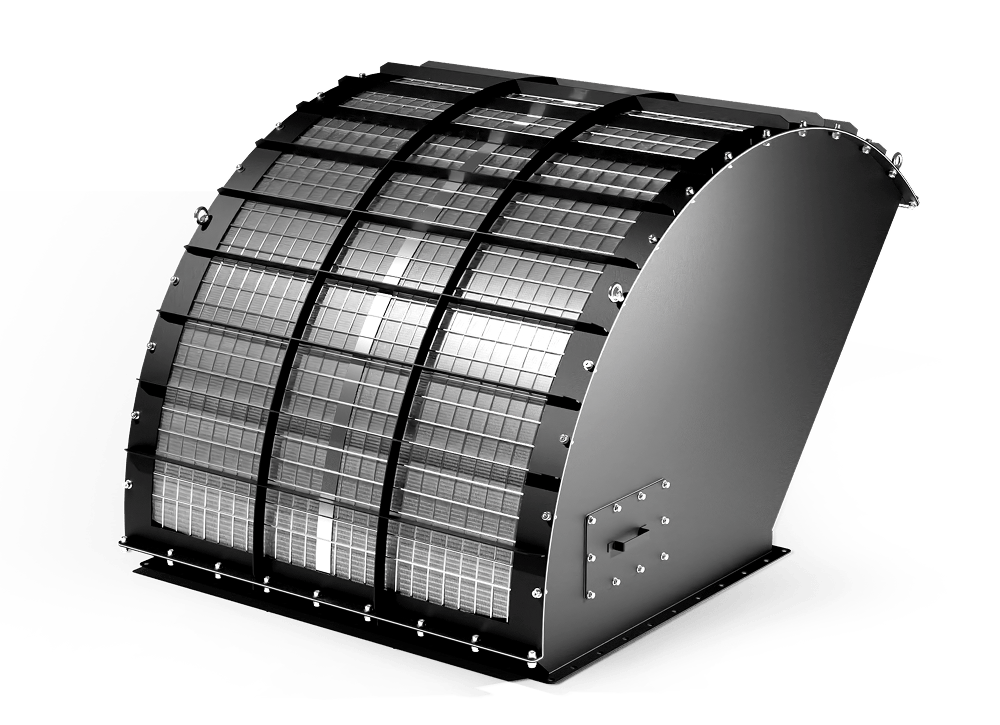

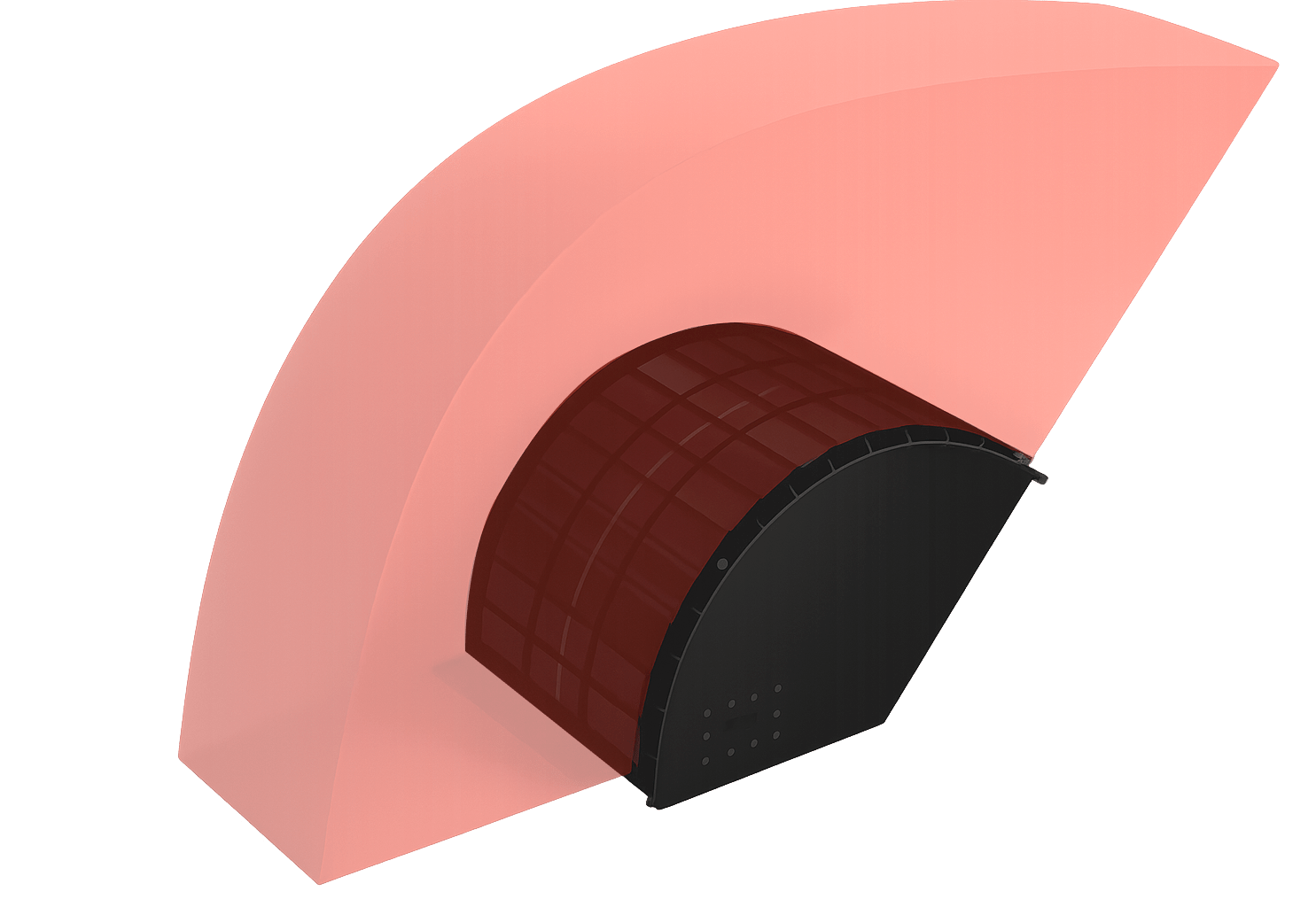

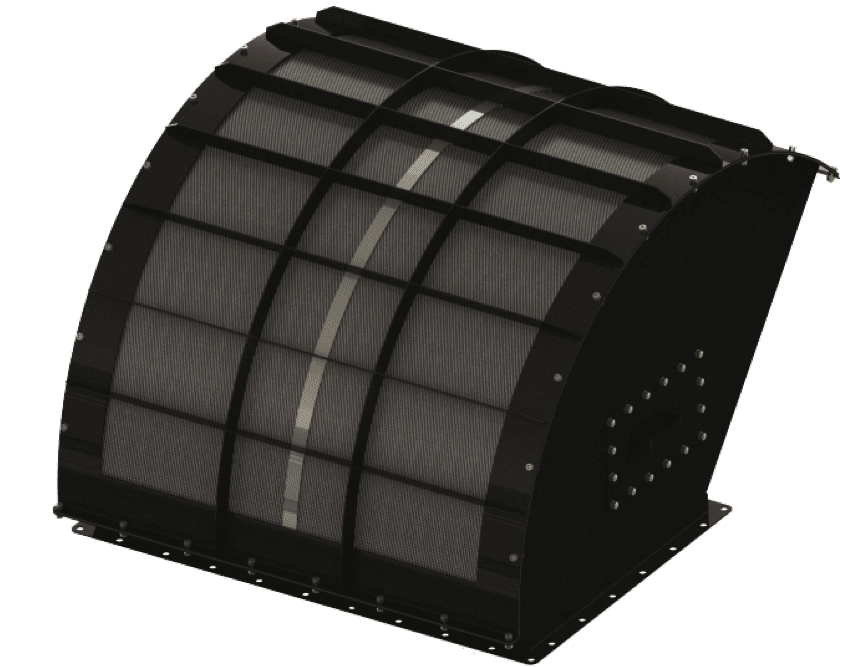

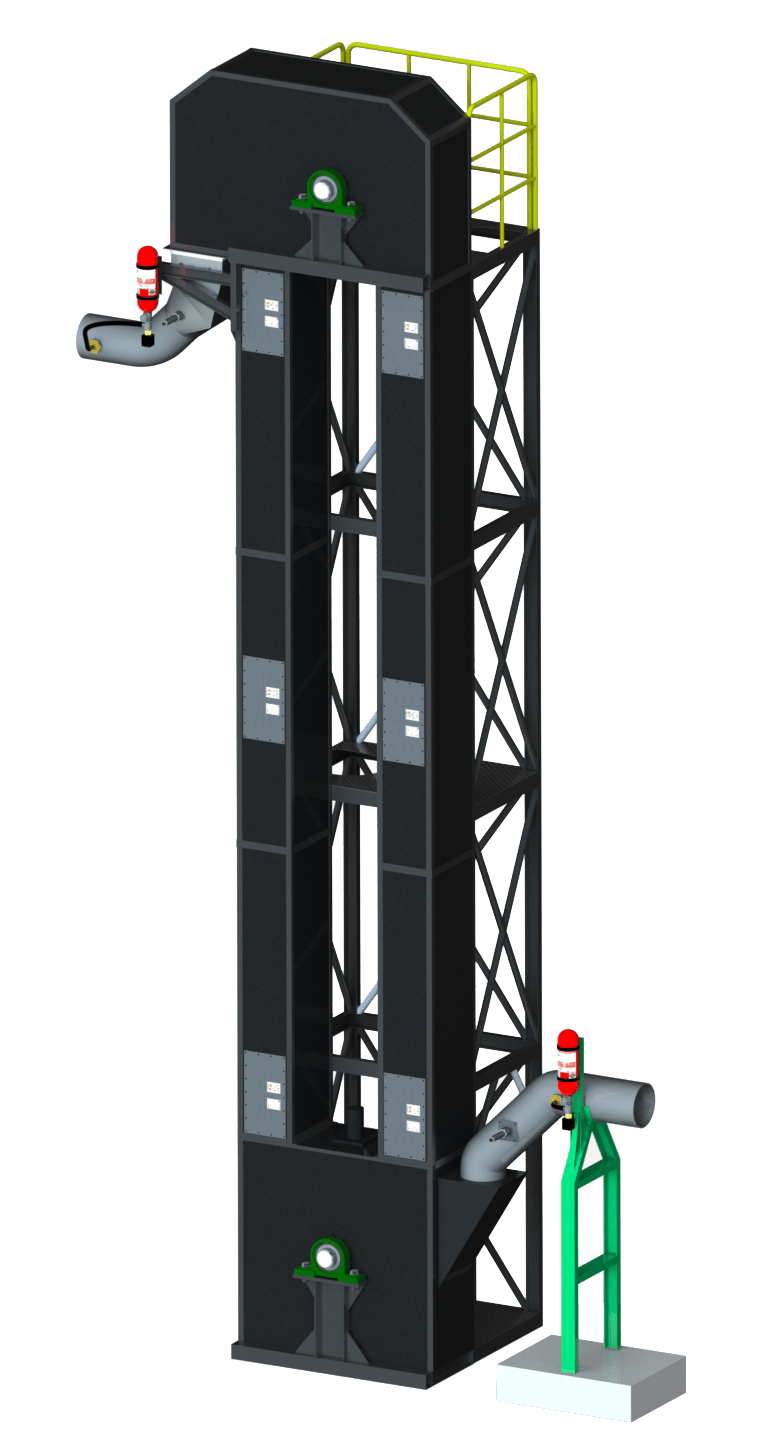

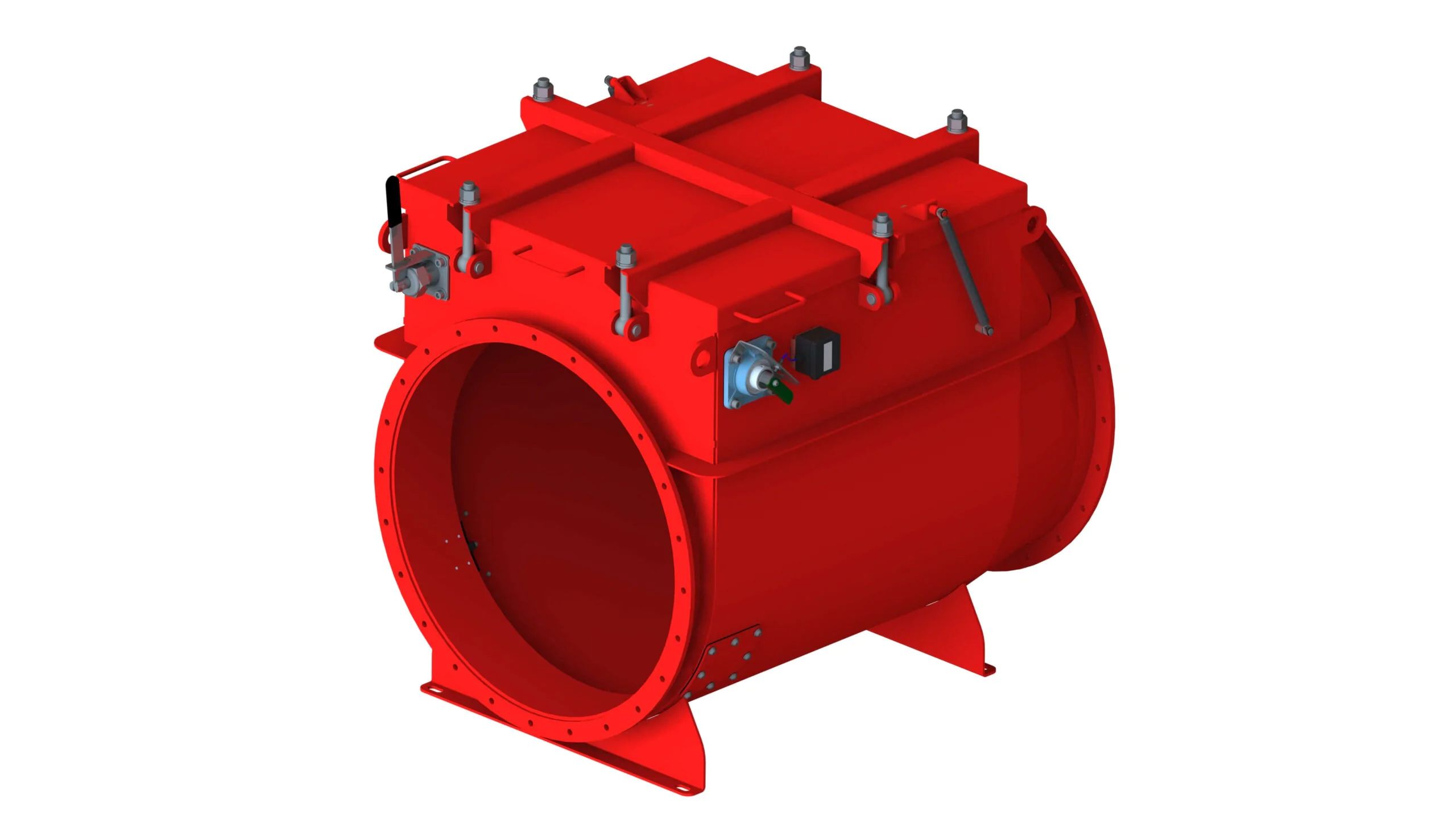

Flameless venting device FLEX R PRO is a passive explosion protection device for releasing explosion energy in enclosed spaces. The explosion relief panel reduces the overpressure of the shock wave and prevents the destruction of structures due to its effects. The curved, mesh-like dispersion surface reduces the temperature of the explosion products and keeps open flames from escaping to the outside.

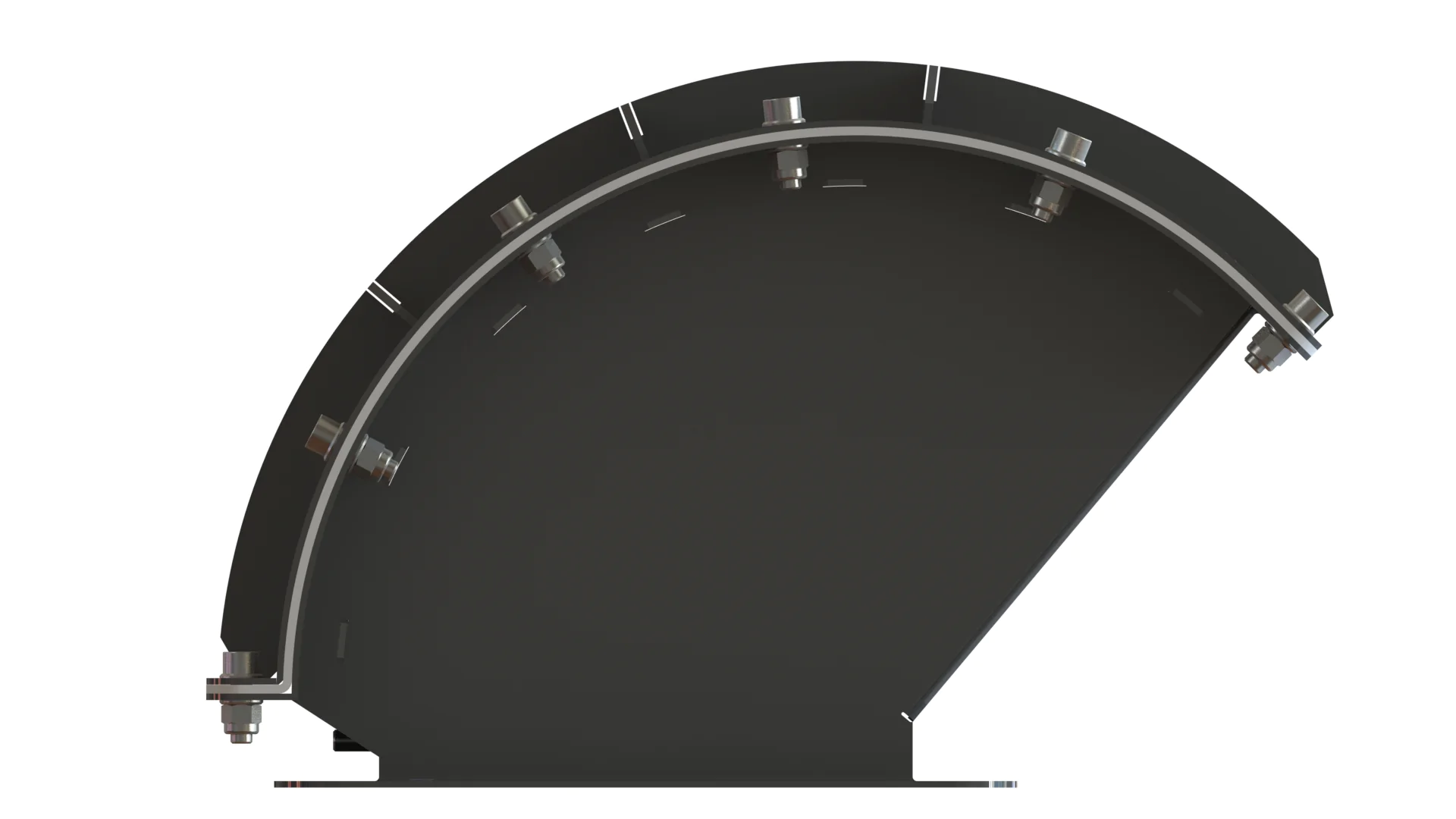

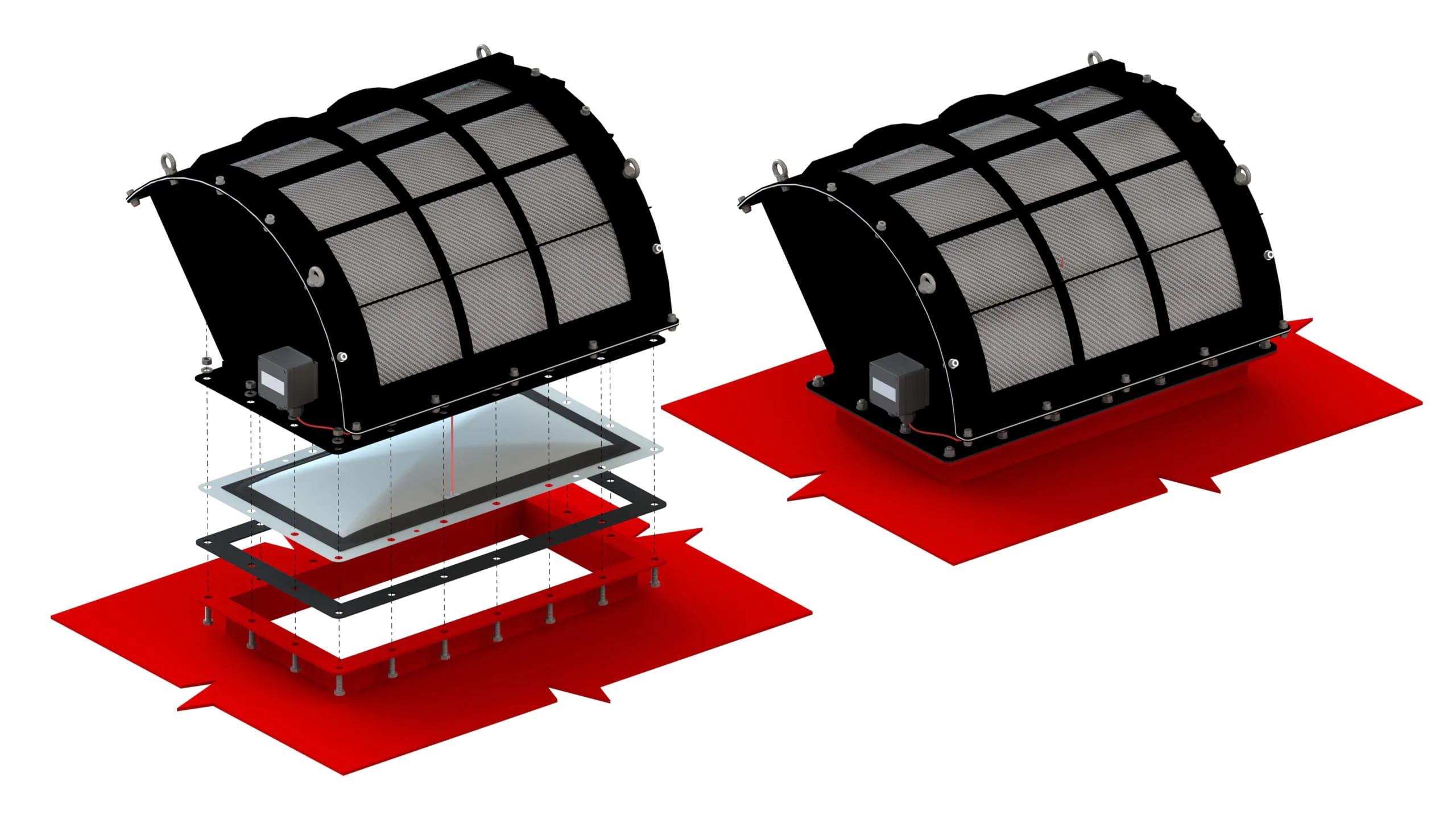

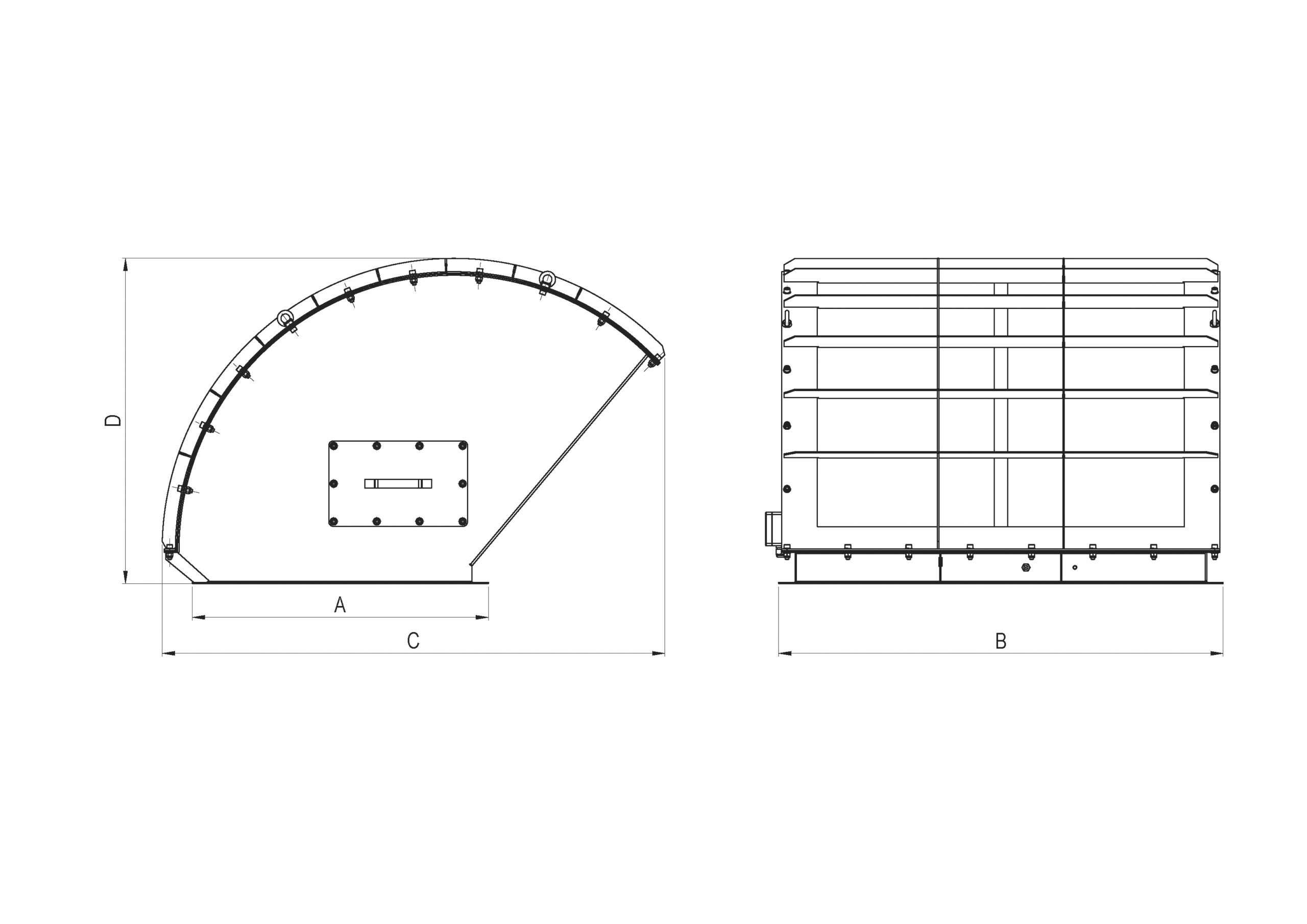

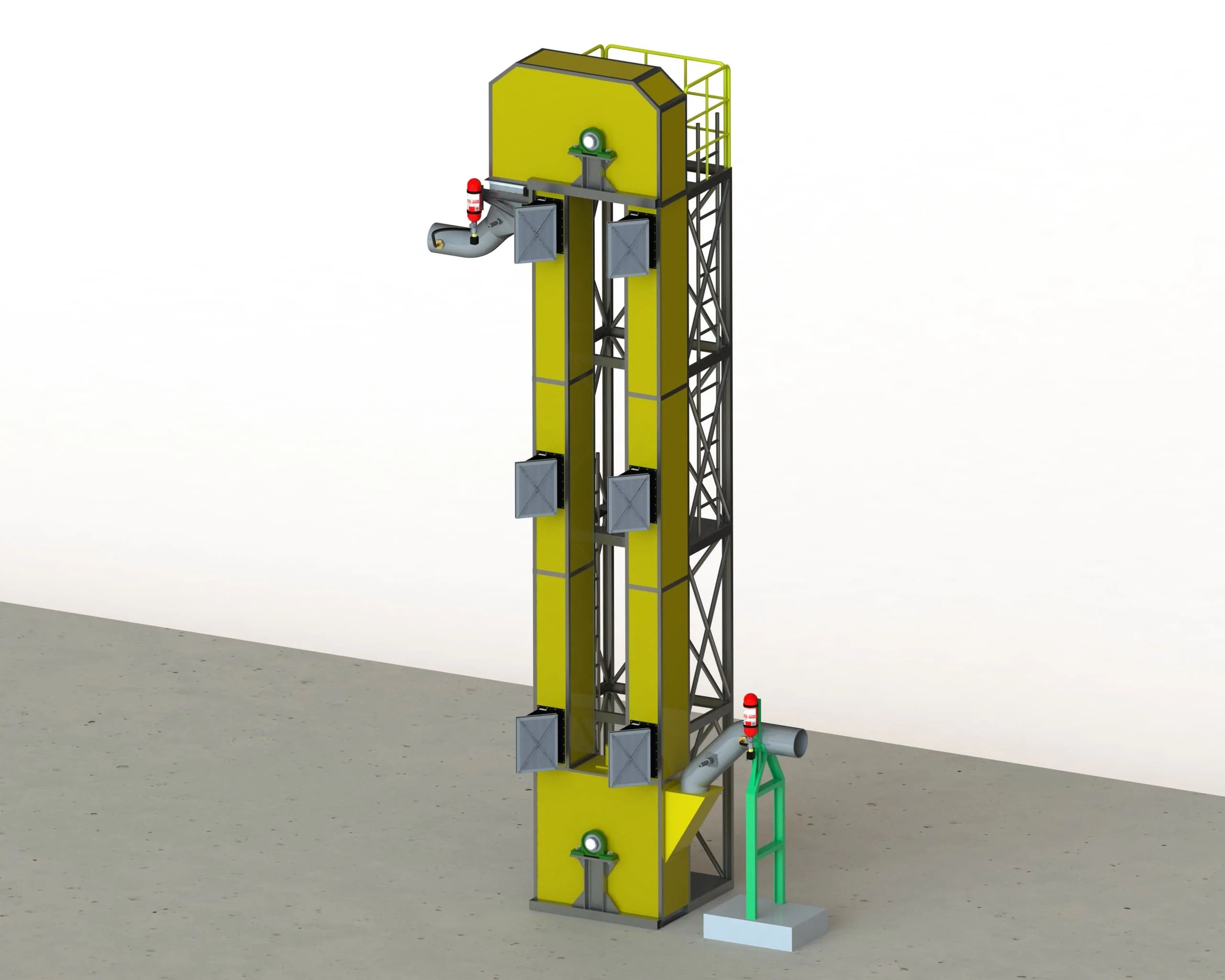

The smooth shape of the FLEX R makes it suitable for small or complex equipment. The flame arrester can be installed horizontally and vertically as well as at an angle.

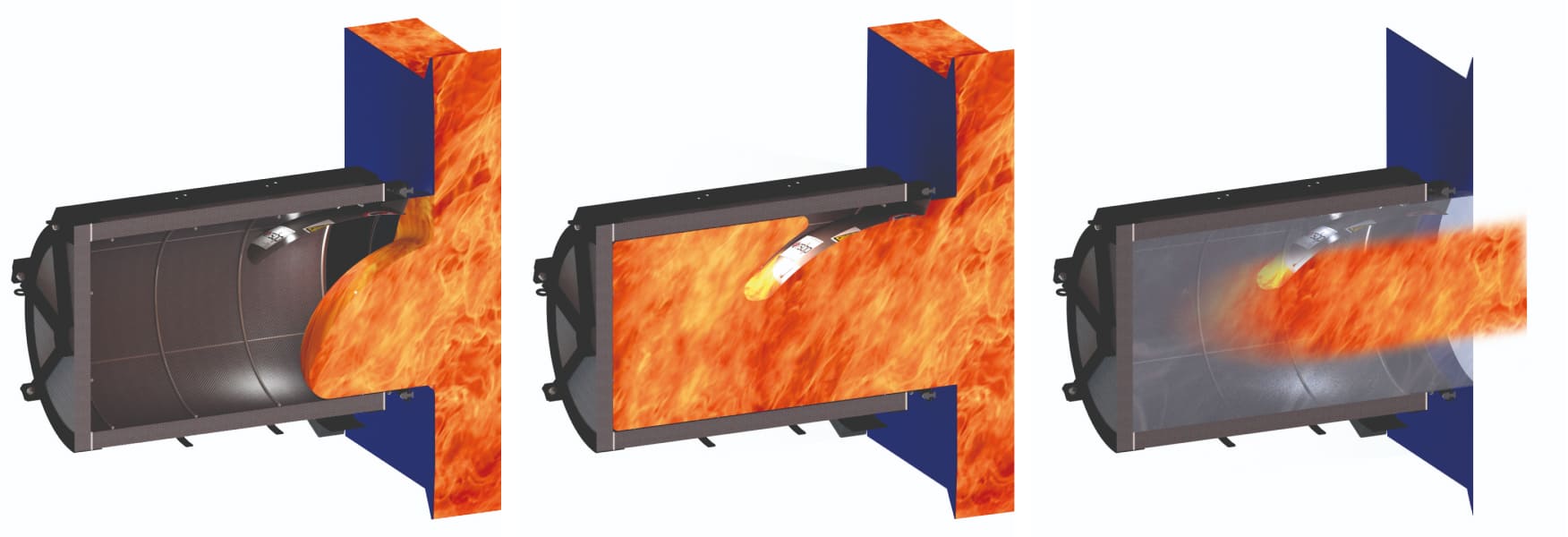

When an explosion occurs, the pressure builds up in the equipment. The alarm gives a command to open the explosion-discharging diaphragm VMP. Flames, burning dust, gases are discharged into the FLEX device.

Temperatures of up to 1500°C can be reached during a normal explosion pressure release. When exploding light metal powders, e.g. aluminum and magnesium, the temperature may be around 3000 °C.

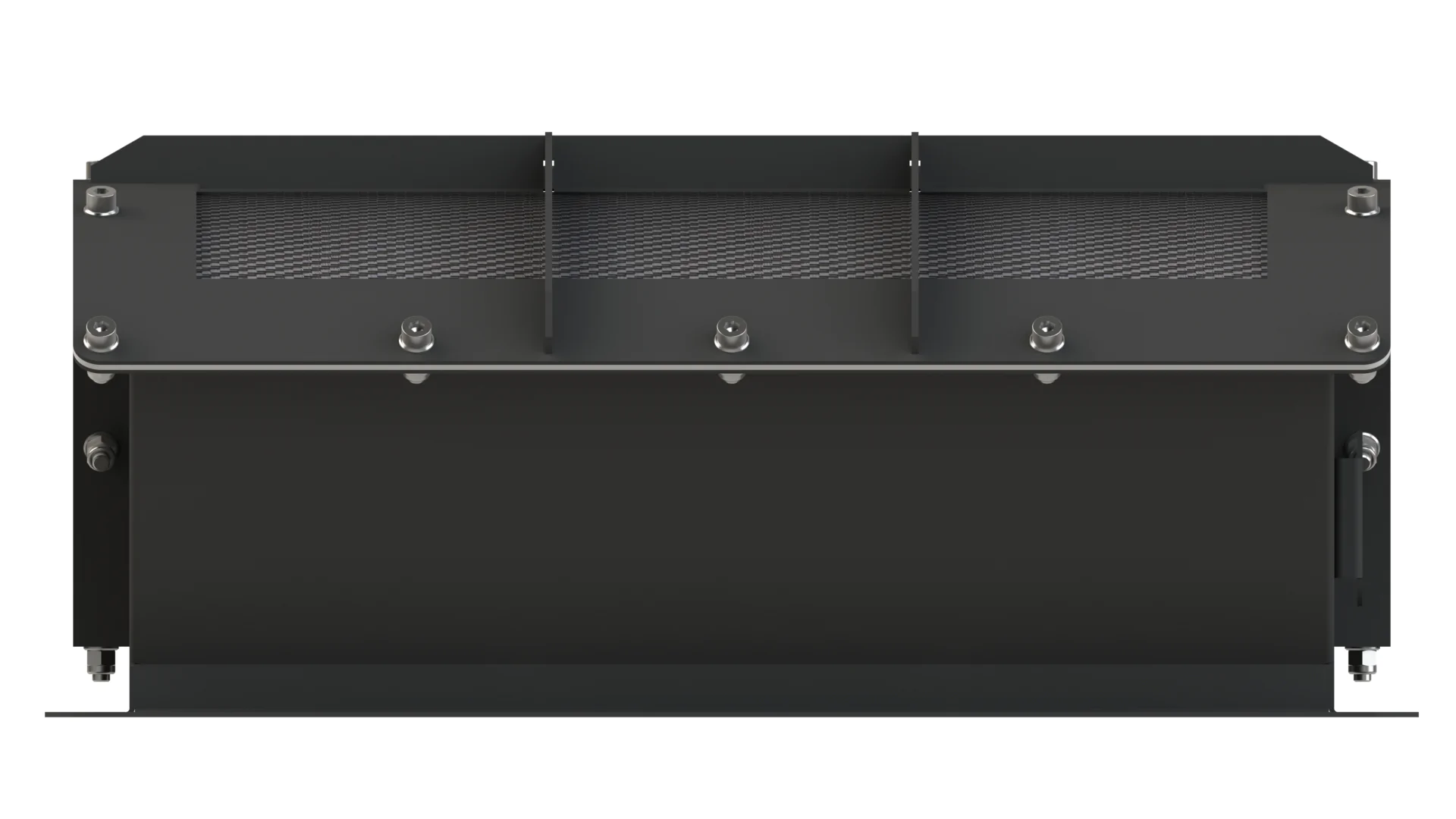

The released explosion products pass through a system of grids in the dispersion surfaces, where they are cooled down and decelerated to safe levels.

- The FLEX R flameless venting device provides explosion protection in enclosed areas. In case of equipment failure, there is only a slight increase in ambient temperature and pressure, which is safe for people and technical structures.

- Due to the curved surface, it is suitable for small or complex equipment.

- Economical to operate. Flame arresters are designed for multiple applications. After an explosion, it is sufficient to replace the protective cover if it is used.

- Resistant to dust and mechanical damage as well as process pressure fluctuations.

- Integrates into existing equipment and automatic control system.