Introduction to Dust Explosion Safety

It is no secret that some chemicals have explosive properties. For example, information about gasoline vapor or natural gas explosions is not surprising. However, when it comes to dust explosions, many are surprised to learn that dusts from plant (and other) materials can explode. For this reason, there are many safety standards, directives, and other regulatory documents governing the handling of explosive dust. Dust explosion safety a necessary measure in modern realities.

What is a Dust Explosion?

A dust explosion is an extremely rapid combustion of dispersed fine solid particles in an enclosed volume of air. Due to the often very small particle size of the dust, industrial enterprises pay special attention to preventing the spread of dust beyond technological processes. Combustible dust safety answers the question of how to avoid incidents.

Importance of Combustible Dust Safety in Industrial Environments

Dust poses serious risks to workers' health and, if systematically inhaled, can lead to the development of occupational diseases in the future. In addition, there are risks of dust explosions that take lives every year. That is why it is so important to take measures that will prevent the occurrence of dangerous situations and provision dust explosion safety.

Common Sources of Combustible Dust in Industry

The primary sources of combustible dust in industry are technological processes involving the processing of plant materials or inorganic materials whose dust has explosive properties. Therefore, in industrial enterprises, ensuring the combustible dust safety is a primary task for all employees.

Industries at Risk for Dust Explosions and Materials That Can Cause Dust Explosions

When considering individual industries for the presence of explosive dust in their processes, a ranking can be made based on the number of processes requiring special attention to ensure dust explosion safety and protection against dust explosions:

- Agricultural Industry: Performs functions of production, storage, transportation, and processing of agricultural raw materials. The most common types of explosive dust which can cause dust explosions include grain dust, corn dust, bean dust, tobacco dust, sunflower seed dust, and other types of agricultural products.

- Food Industry: Processes agricultural raw materials and produces food products from these raw materials. The main types of explosive dust in this industry include flour dust, sugar dust, starch, pea protein, dry milk, coffee, cocoa, soy and wheat protein, and other types of food products.

- Woodworking Industry: Engages in wood harvesting, processing, and manufacturing various products. The most dangerous type of dust in this industry is fine wood dust. Less dangerous types include wood shavings and chips. Combustible dust safety is very relevant for this industry.

- Energy Industry: Operates energy facilities to obtain energy resources and deliver them to consumers. The most dangerous type of dust here is dust from various types of solid fuels, such as coal dust.

- Pulp and Paper Industry: Processes pulp and paper raw materials to produce various products. The greatest risks in this industry are associated with the formation of paper dust and other types of dust containing cellulose.

- Chemical and Pharmaceutical Industries: Process chemicals, including bulk materials, to produce various consumer products. These industries have a wide variety of explosive dust types, both organic and inorganic. Practically the entire periodic table is represented here.

- Mining Industry: Extracts and processes minerals, including solids that require grinding to ensure the production of various products. The mining industry faces dangers associated with the formation of dust from various ores, metals, or stones, including coal dust, coke dust, brown and wood coal, and other types of minerals.

- Metallurgical Industry: Processes metal ore to produce metal products. This includes steelmaking and other metal processing industries. The most common types of explosive dust in this industry are aluminum, titanium, and magnesium dust. It should be noted that metal dust types are the most dangerous compared to other substances and, in the event of an explosion, lead to the most destructive consequences. This is due to the very high explosion index (Kst) and maximum explosion pressure (Pmax) of metal dust. Combustible dust safety is less relevant for metallurgy, but it cannot be forgotten.

How Dust Explosions Occur

A dust explosion, like any other incident involving a threat to the life and health of workers, is a combination of human errors, systemic failures in safety procedures and ordinary accidents that occurred in one period of time. Dust explosion safety helps reduce risks to an acceptable level.

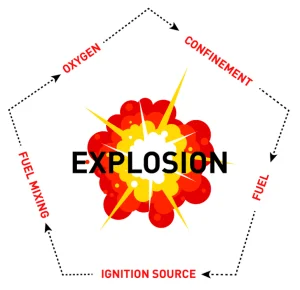

The Dust Explosion Pentagon: Key Elements

The dust explosion pentagon is a conceptual model of an explosion consisting of five elements:

- There must be explosive dust;

- There must be a confined volume of air;

- The explosive dust must be evenly suspended in the confined volume of air;

- There must be an oxidizer, such as oxygen in the air;

- There must be an ignition source.

Primary and Secondary Explosions: Understanding the Difference

In enterprises where explosive dust is generated, there are often places where dust can accumulate in layers. If periodic cleaning of production areas is not organized, additional risks arise for the life and health of workers, as well as for buildings, structures, and company property. These risks are associated with the likelihood of secondary explosions. When all five elements of the dust explosion pentagon appear simultaneously in one place, an explosion of a certain power and destructiveness occurs, depending on the type of dust, its concentration, and the area of dispersion. The primary explosion raises dust that has accumulated on various surfaces into the air, leading to a significantly more powerful and destructive secondary explosion. It is important to remember this and never neglect cleaning areas where dust deposits accumulate. Dust explosion safety includes measures to control the maintenance of cleanliness and order.

Best Practices for Dust Explosion Safety

When working with explosive dust, it is necessary to adhere to the standard hierarchy of risk management measures and first consider the possibility of excluding the dust-generating process from the technology. If exclusion is not possible, the possibility of replacing the process with another, less dangerous one should be evaluated, for example, by automating manual processes of raw material unpacking or using raw materials with lower explosive properties. The next element of defense against dust explosions is the use of explosion protection devices, which help protect workers from the harmful effects of explosions and protect equipment and production complexes from destruction. The final element of protection against dust explosions is administrative control, which includes organizational and regulatory measures as well as measures aimed at identifying and eliminating potential ignition sources. Combustible dust safety is a set of measures that preserve life and health.

Housekeeping and Dust Control Measures

The simplest way to combat dust explosions is to organize a high-quality and effective system for maintaining cleanliness in production areas. In building such a system, both organizational and technical means should be used.

Ventilation and Dust Collection Systems

Technical means of ensuring the absence of dust deposits include ventilation: both general ventilation inside the premises and local ventilation in places where potential sources of pollution are located. And for dust collection, it is recommended to use technical vacuum cleaning devices, which can be portable and stationary, providing automatic cleaning of premises. Dust explosion safety is obliged to ensure the proper functioning of this equipment.

Proper Storage and Handling of Combustible Materials

In addition to regular cleaning, do not forget about organizing the storage of flammable materials properly. The premises must be equipped with automatic alarm and fire extinguishing systems, and personnel involved in the storage and movement of hazardous substances must be trained and instructed to perform their work duties.

Identifying and Eliminating Ignition Sources

To ensure the safety of industrial enterprises, it is necessary to conduct an dust hazard analysis which helps to identify ignition sources and subsequently take measures to eliminate them. One of the elements of effective risk assessment is the identification of ignition sources. As a rule, the most common source of ignition is sparks generated mechanically and also static electricity. Timely maintenance of equipment and organization of protective grounding of electrical equipment will help eliminate these risks.

Combustible Dust Safety Regulations and Standards

There are many rules and standards that regulate safety measures when working with explosive dust.

OSHA Guidelines for Combustible Dust Safety and National Fire Protection Association (NFPA) Standards

The most stringent requirements for organizing work processes are set by organizations such as OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association). Combustible dust safety is the primary task for these governing bodies. These organizations, through statistical analysis of incidents and investigation results related to dust explosions, have developed a comprehensive approach to ensuring production safety in the following main areas:

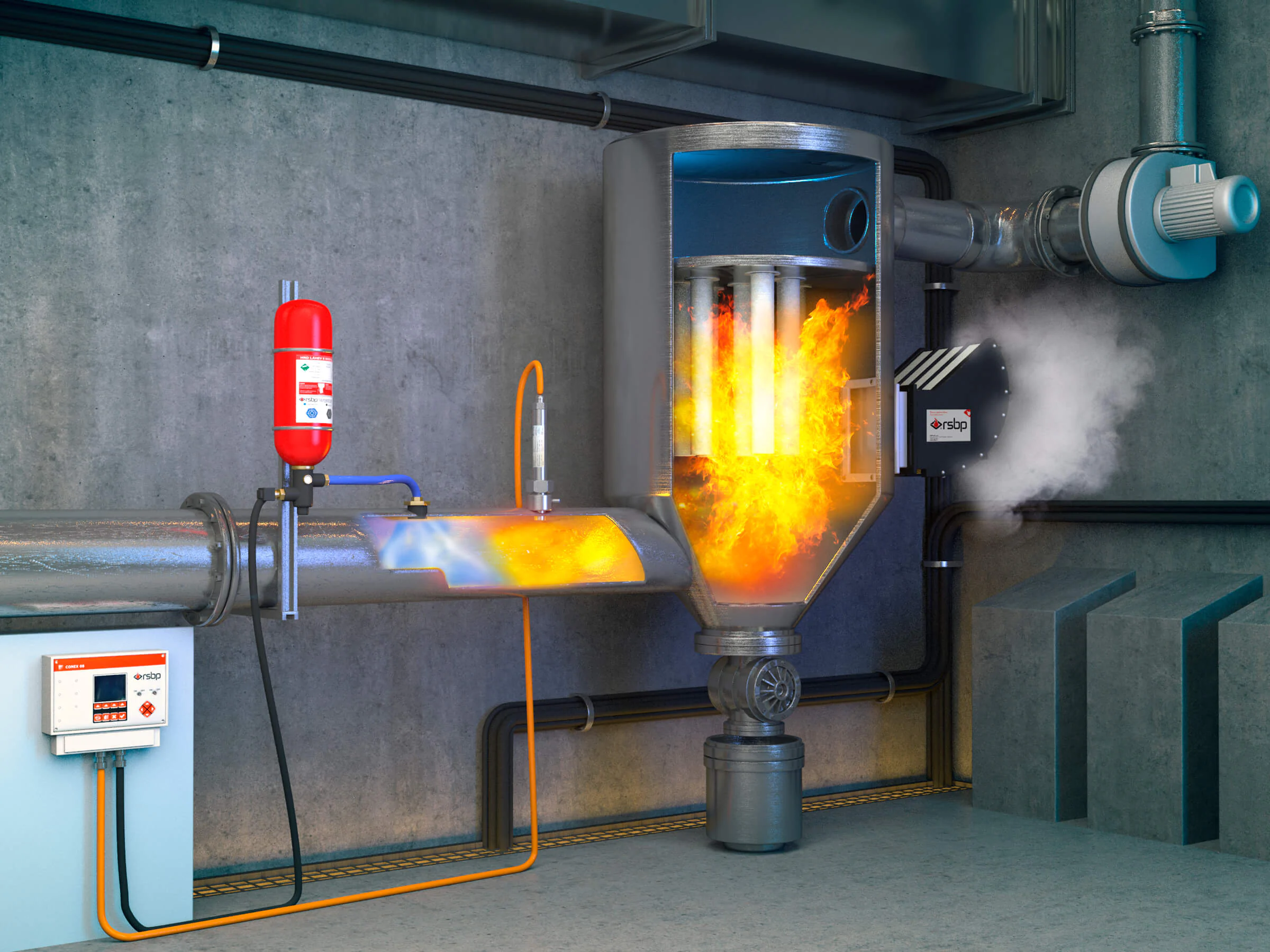

- Protection of technological equipment by venting excess explosion pressure directly into the atmosphere (explosion vent panels);

- Protection of technological equipment by flameless venting of excess explosion pressure (flame arresters);

- Protection of buildings and structures with lightweight construction elements;

- Protection of equipment using active systems for chemical suppression of explosion energy (HRD systems);

- Protection of equipment using active systems for chemical isolation of explosion propagation (HRD barriers);

- Protection of equipment using mechanical devices for isolating explosion propagation (check valves, fast-acting gates).

Technologies for Preventing Dust Explosions and Reducing the Severity of the Consequences of Dust Explosions

There are different types of equipment the purpose of which is to reduce one of the two components that form the risk level: the probability of a dust explosion and the severity of the consequences caused by the explosion.

Explosion Venting and Suppression Systems

Explosion protection devices are designed to reduce the consequences of explosions. This is achieved by releasing excess explosion pressure into the environment or by suppressing the explosion energy inside the equipment. Explosion venting is used if the process equipment is located outdoors. If the equipment is located indoors, then it is necessary to use active explosion suppression systems (HRD systems) or flameless venting.

Monitoring and Detection Systems for Dust Concentration

To prevent the formation of dangerous concentrations of dust in indoor air, means for monitoring the concentration of dust particles can be used. These tools include automatic gas analyzers. Such equipment helps to identify hazards associated with explosive dust. Combustible dust safety is also a means of preventing explosions.

Conclusion

Dust explosions, which we unfortunately observe in the world around us, although frightening with their destructive consequences, are quite logical in nature. By eliminating at least one element of the so-called dust explosion pentagon, we reduce the likelihood of an explosion to acceptable levels. Our main task is to create an effective safety culture in modern industrial enterprises that have to deal with the formation of explosive dust in their operations. Dust explosion safety is a common task for all categories of employees.