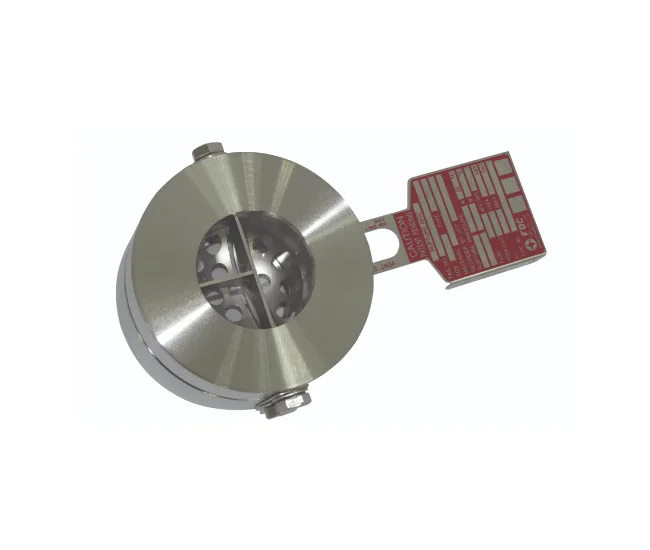

A rupture disc is a safety diaphragm device that ruptures when the system is over-pressurised beyond critical pressure. By rupturing, the disc relieves pressure, which ultimately helps protect equipment and human life.

The rupture disc consists of a special material, has a special shape, and has no size limitations. The rupture disc has a wide range of applications, is easy to install and adjust. In addition, the rupture disc is a thermal protection against high and low temperatures, specially designed to increase the durability of equipment.