Installation

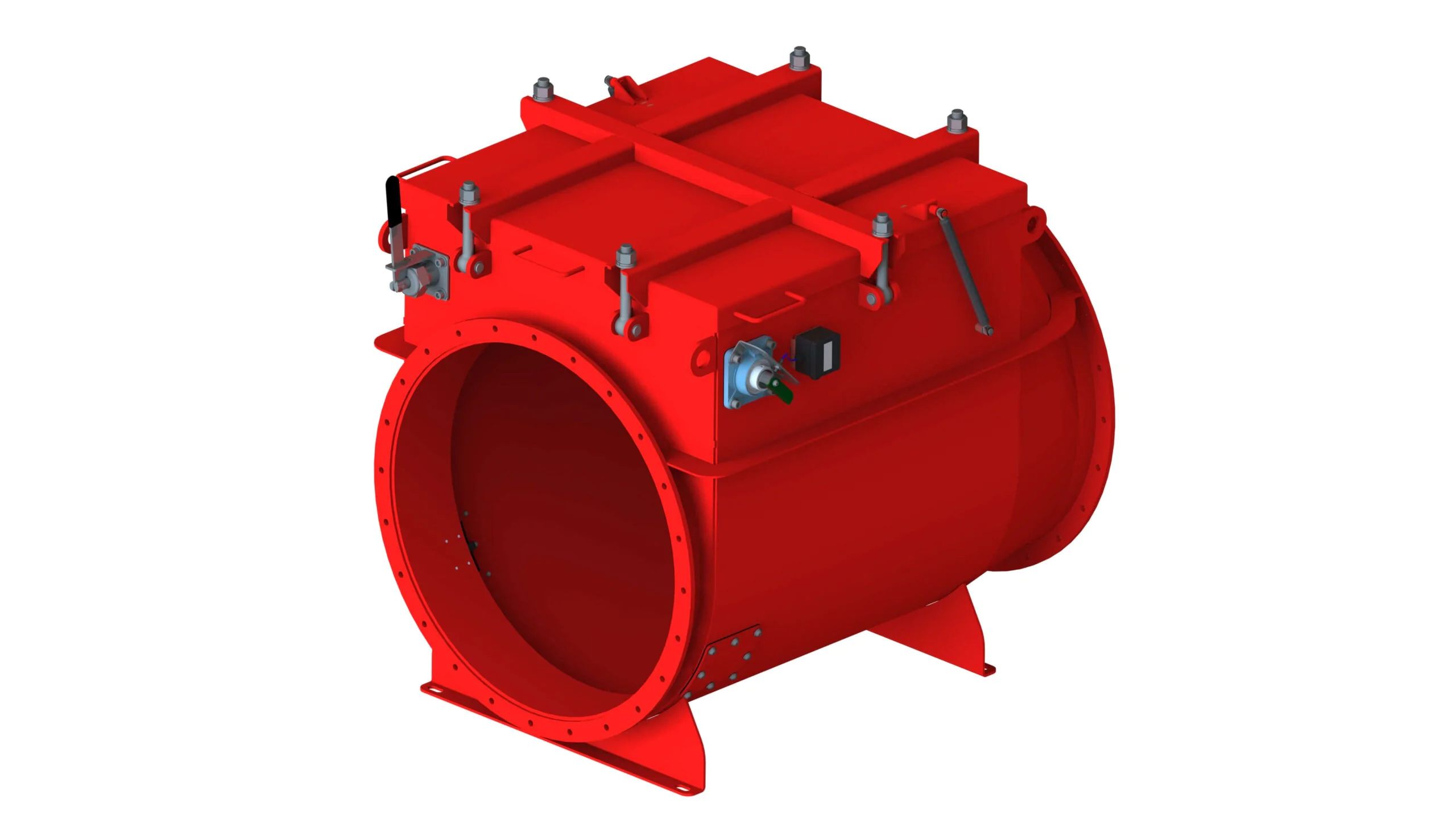

VMP SU is supplied either with top frame, seal or separately. The safety vent panel must be checked before installation:

- Integrity of the original packaging;

- The membrane itself and the seals are undamaged;

- The connecting material is present, if it is included in the scope of delivery;

- No damage to the indicator, if ordered.

The installation of explosion vent panels requires a design. It determines, among other things, the number of process openings on the equipment to be protected to release the explosion and the number of VMPs respectively, their type, the possibility of operation under existing conditions. The project is to be developed by a specialized company. For example, ATEX.CENTER.

The vent panels are installed in accordance with the manufacturer’s instructions and the explosion protection project. The work consists of two basic steps. First, the mechanical installation is performed, followed by the installation and adjustment of the electrical part.

The installation of each vent panels must be recorded in a special logbook or operating book with the date, initials and signature of the authorised person.

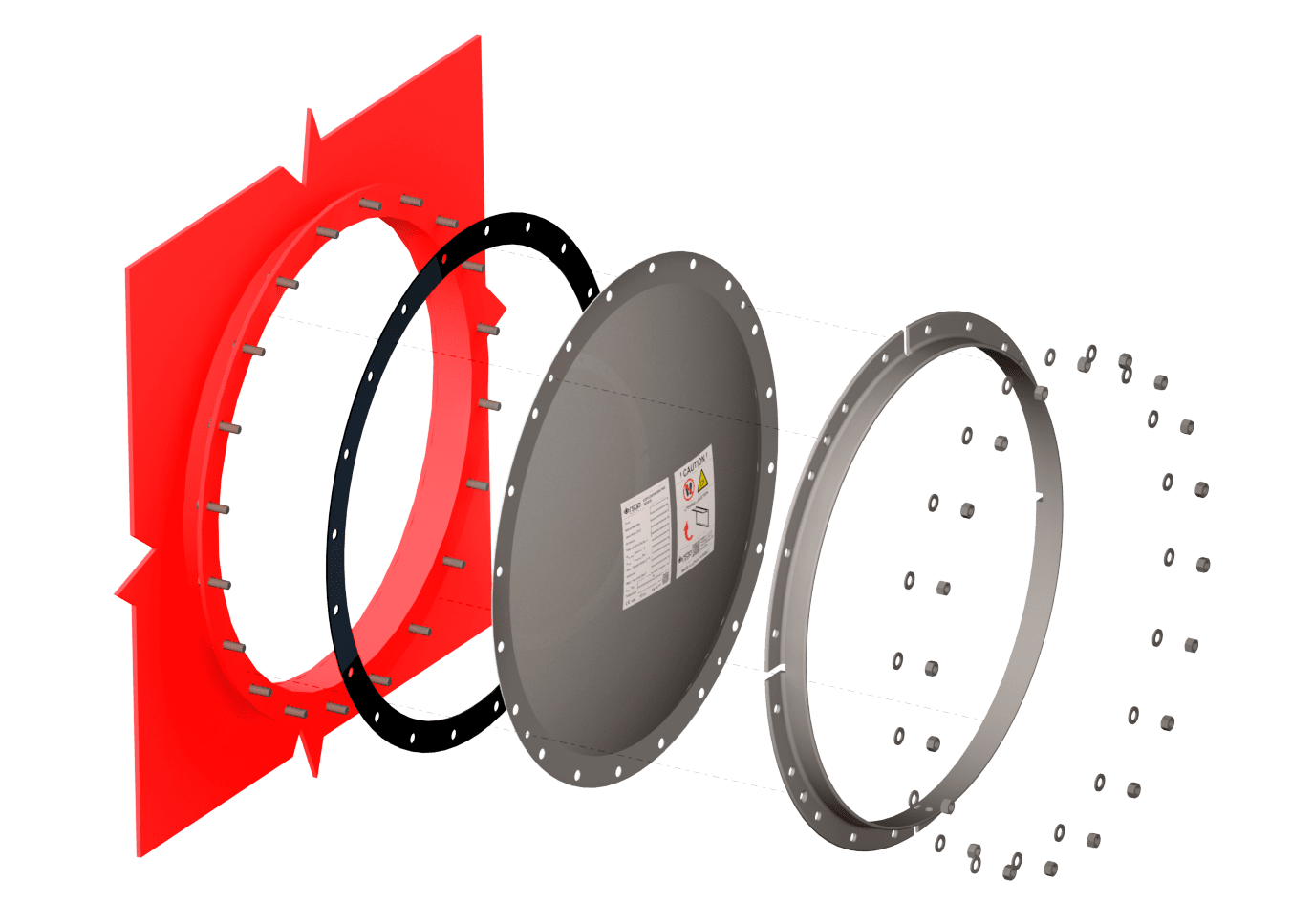

The scope of delivery includes:

- Consignment note

- EU Declaration of Conformity 2014/34/EU;

- Inspection certificate;

- Operating instructions.

We will provide on request:

- wiring diagram of the indicator;

- technical description of the opening indicator;

- technical description of the spark protection relay;

- Panel wiring diagram;

- Checklist;

- The operating logbook.

Maintenance

The maintenance manual is included in the scope of delivery and is used as a basis for the operator’s documentation. In this manual, the maintenance intervals are determined.

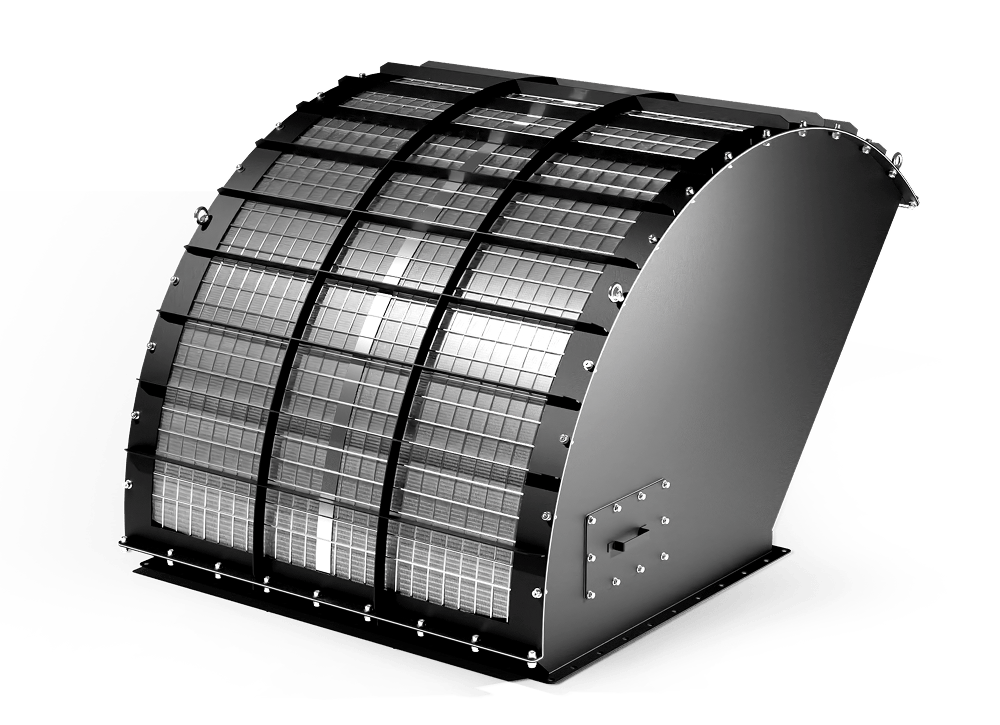

Maintenance of the panel consists of periodic inspection for cleanliness and damage, corrosion. Basic rules:

- All operations must only be carried out with the equipment switched off;

- Inspect the VMP for cleanliness and damage every shift;

- Perform dusting and screw connection checks at least every six months or more frequently depending on the operating conditions;

- Instruct employees on safety measures when working near the explosive membrane immediately after its installation (hiring a new employee) and at least once a year thereafter – the VMP is classified as an injury-prone equipment;

- Do not enter the frame space and safety area when the equipment is in operation.

The safety explosion vent panel may only be serviced by the manufacturer, RSBP, or its authorised representative. The service interval is at least once a year.

Optionally

VMP can be equipped with:

- Door opening indicator. This is a diaphragm status indicator. If the VMP is opened the contact will be interrupted and the electrical circuit will be disconnected. The indicators can be magnetic or cable.

- Mounting kits for G1, G2 and G indicators. To be supplied on request.

- Intrinsic safety relay. Intrinsic safety relays are hazardous for life. The relay creates a boundary between the safe and hazardous area.

- Frames for VMP (type SU and D). Needed for mounting those membranes where there are no built-in frames. Made of stainless steel.

- Flanged seals. As standard they are made of EPDM material. As an option it can be replaced with silicone (FDA).

- Thermal insulation. Available on request.