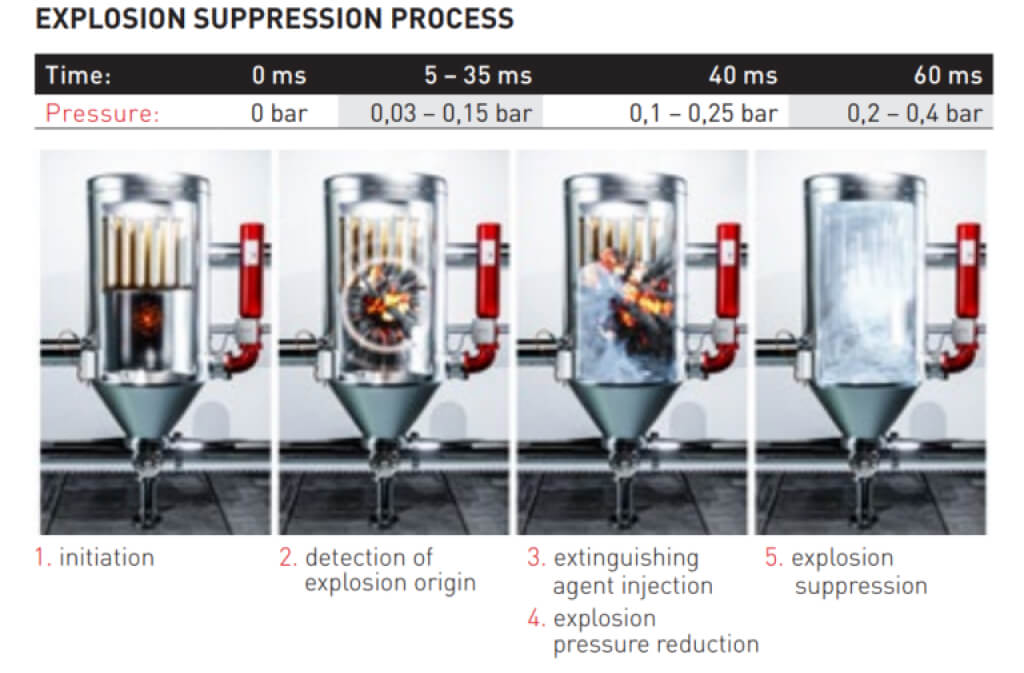

HRD (High Rate Discharge) barrier detects the onset of an explosion and introduces an explosive suppressant into the equipment to limit the spread of the flame front to other items of process equipment.

An initial local explosion causes an increase in temperature and pressure of the dust/air mixture in the pipeline. Highly sensitive HRD barrier sensors react to changes in parameters and transmit an alarm signal to the controller. The controller issues a command to activate the HRD cylinders in the area where an accident might occur. Temperatures and pressures are reduced to safe levels for personnel and equipment, and explosion products do not escape from the equipment. The entire accident containment process takes no more than 60 ms.

The main elements of the HRD Chemical Isolation System are: the detectors, consisting of a sensor, sensor and contactor; the CONEX controller; the HRD cylinder (container) with extinguishing agent.

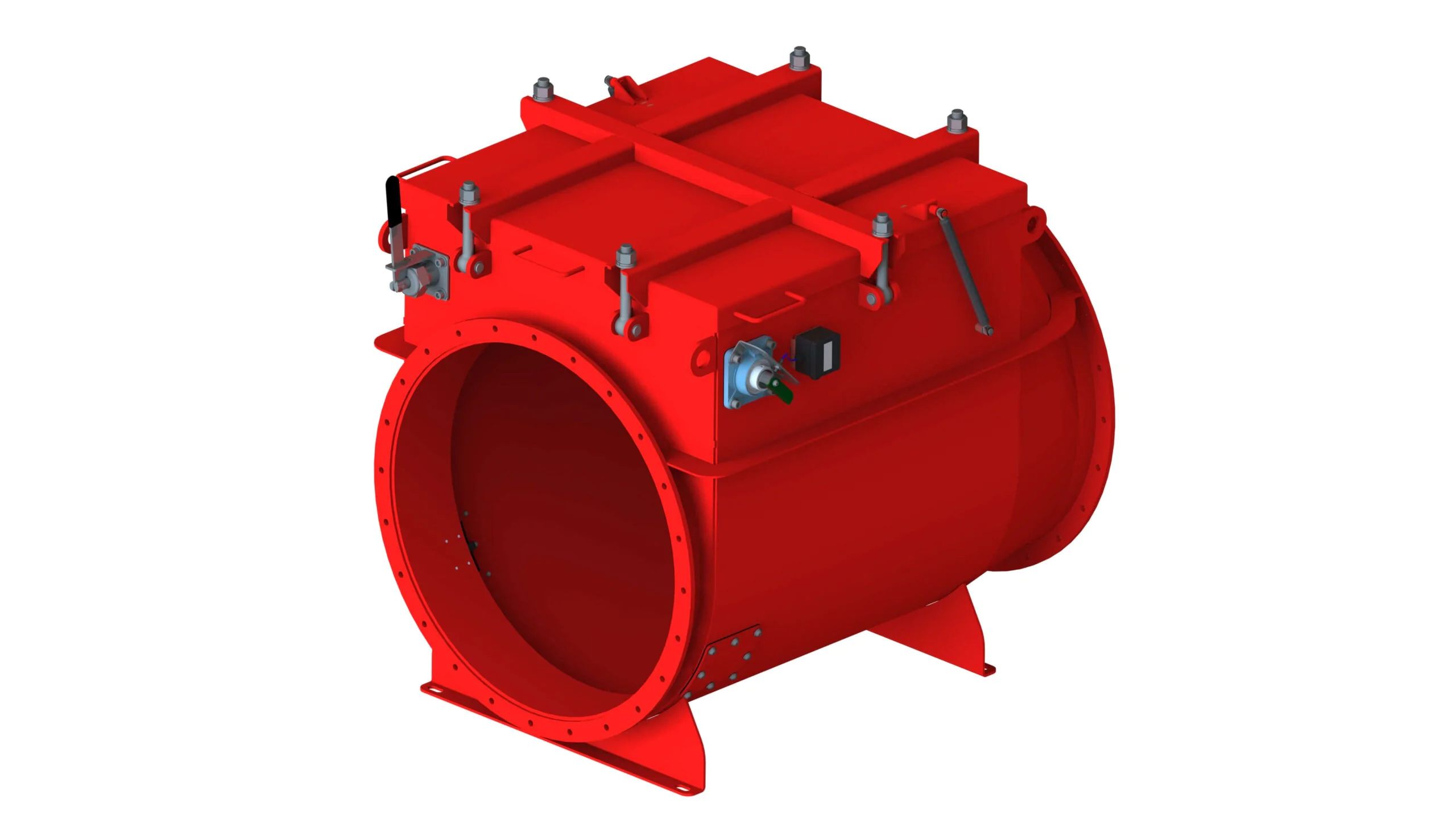

HRD barrier consists essentially of the same components as the HRD system, but it uses nozzles on cylinders with a special geometry. They distribute the explosive suppressant in a flat plume (fan). This forms a barrier of explosive suppressant across the entire cross-section of the pipeline.

- Quickly suppresses an explosion – no more than 60 ms elapses between detection and application of an explosive suppressant. The products of the explosion do not escape outside the equipment.

- Easy to assemble – installation consists of only two steps, according to ready-made drawing sets and assembly instructions.

- Easy to maintain – we will provide a detailed instruction manual, describing the frequency of all operations. The customer’s employees are only required to visually check the cleanliness and integrity of the components and check the pressure on the HRD cylinders monthly.

- Can be applied to most technological processes at storage and processing facilities of vegetable raw materials.

- Installed without changing the design of existing technological equipment.

- Can be used in open areas and enclosed spaces.

- Active components (HRD cylinders) are easy to replace after use.