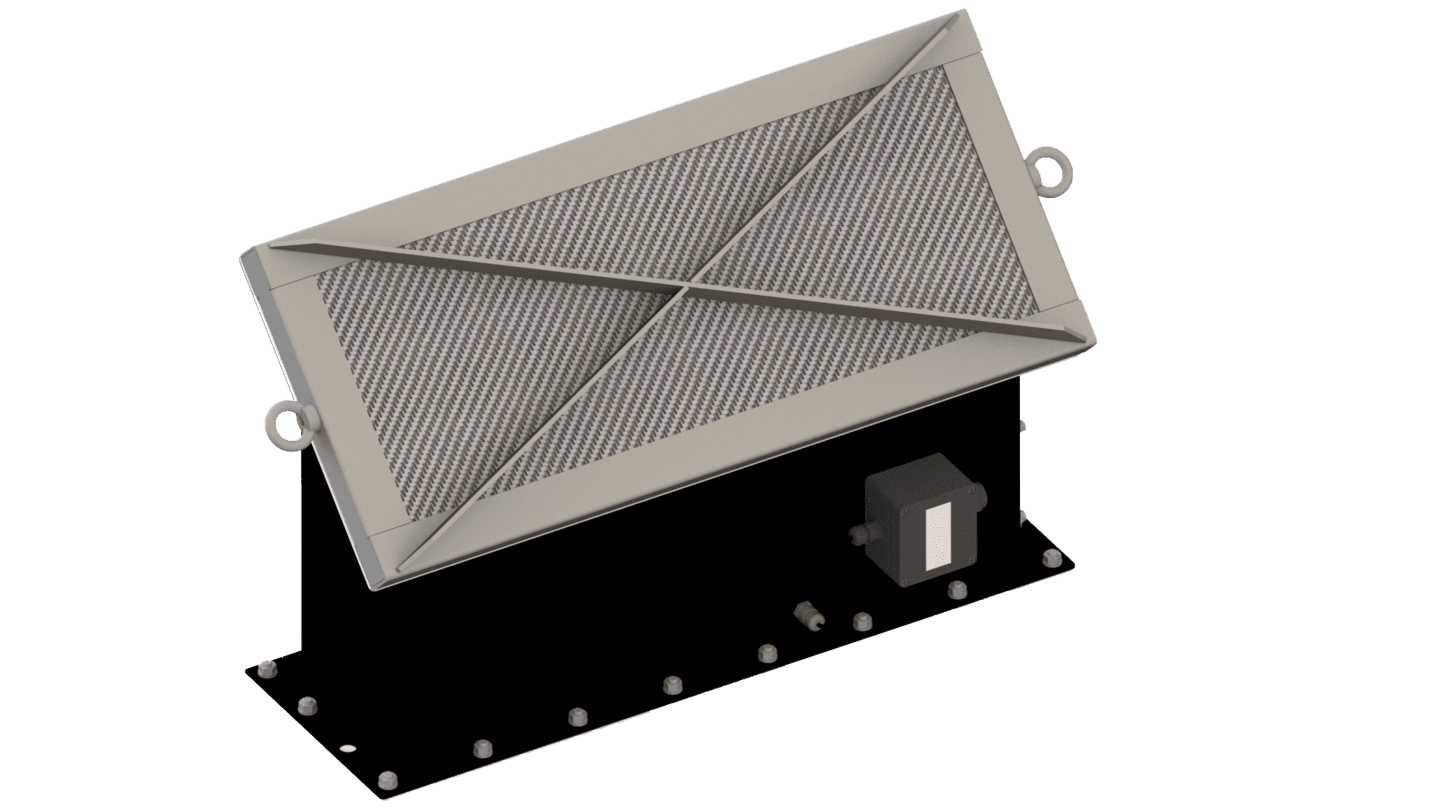

Flameless explosion vent FLEX F PRO is a passive explosion protection device for releasing explosion energy in enclosed spaces. The explosion vent reduces the overpressure of the shock wave and prevents structures from collapsing due to its effects. The mesh diffusion surface reduces the temperature of the explosion products and prevents open flames from escaping to the outside.

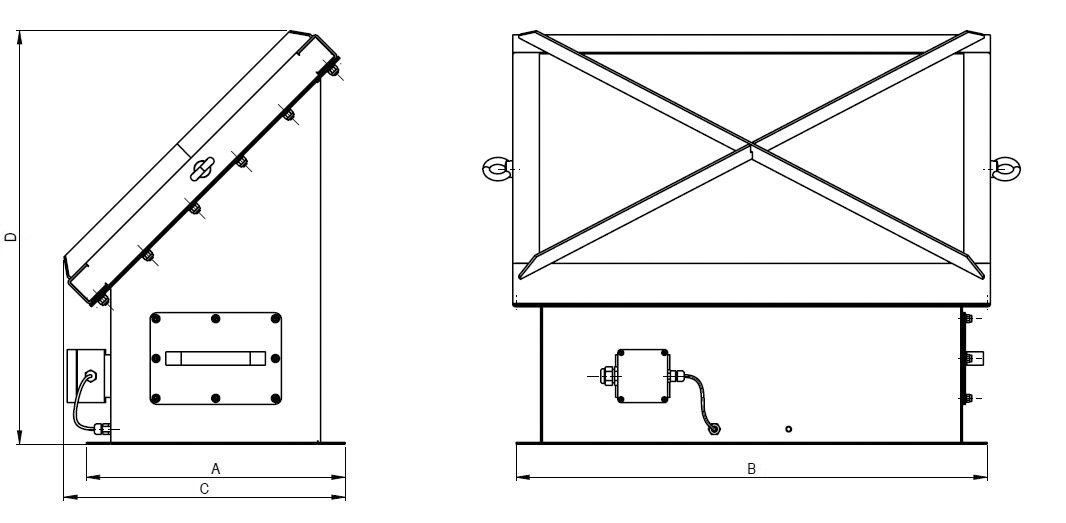

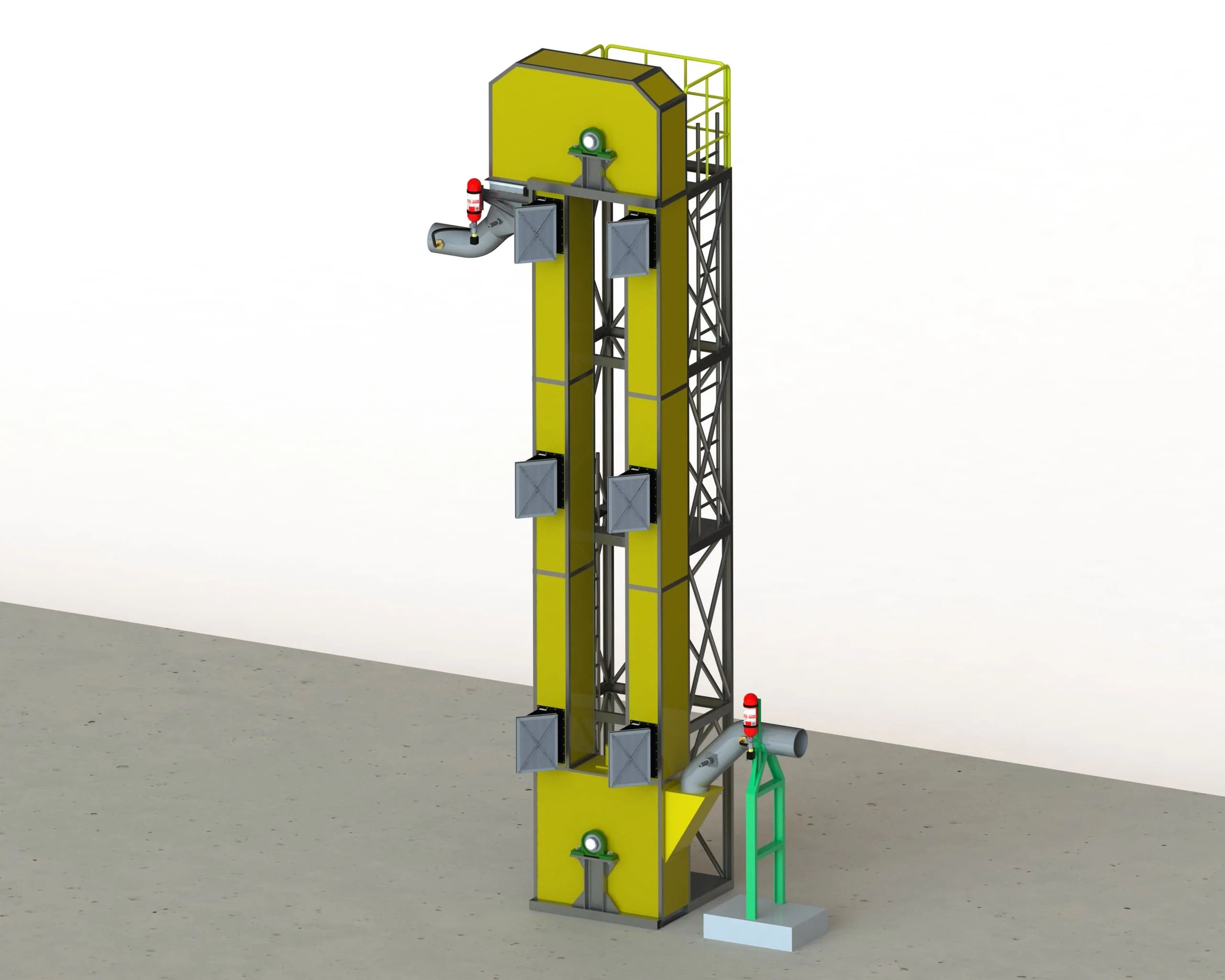

The rectangular flat shape of the FLEX F enables this device to be used on oversized equipment only. However, it is the most economical option for flameless explosion venting devices.

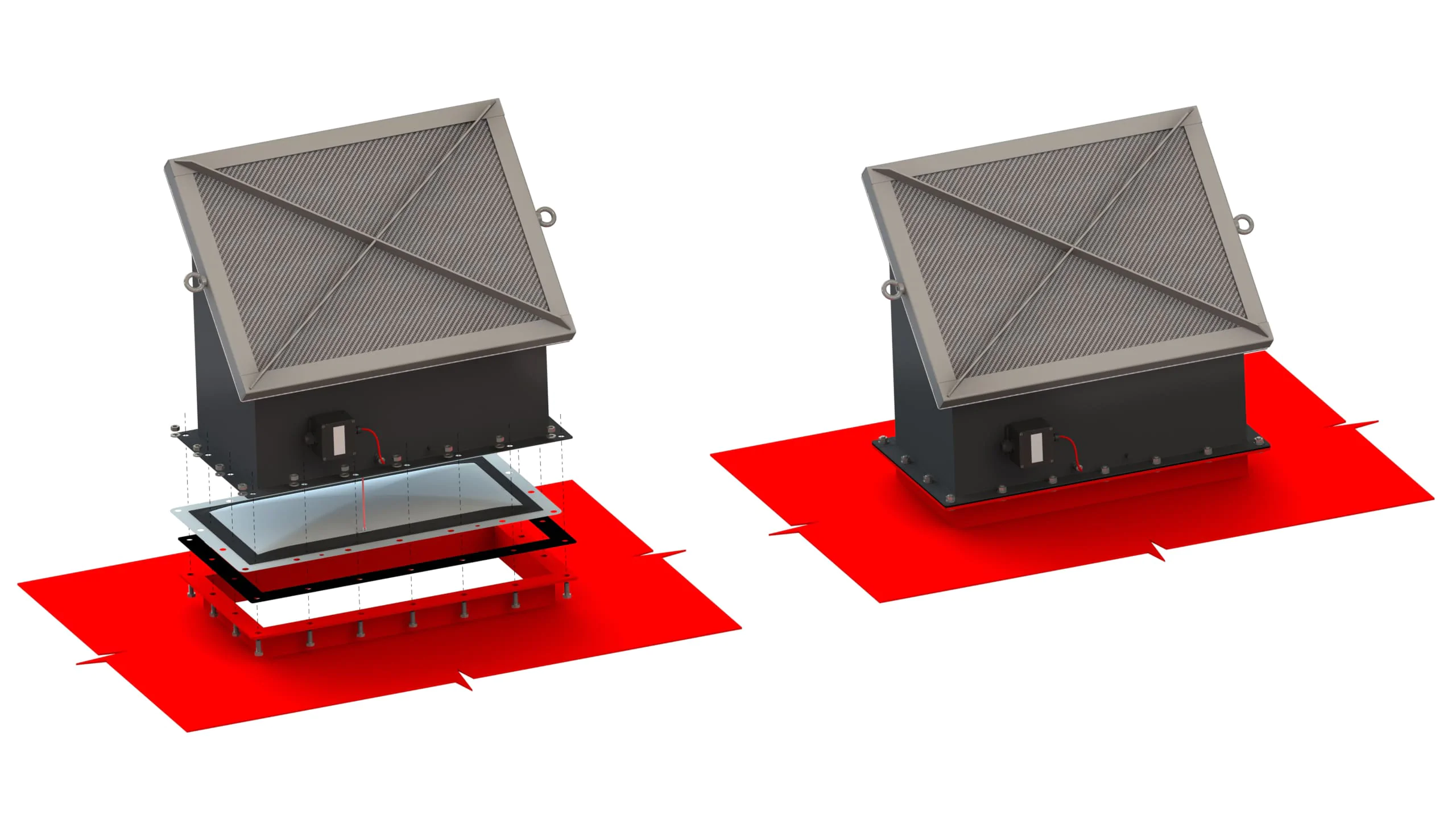

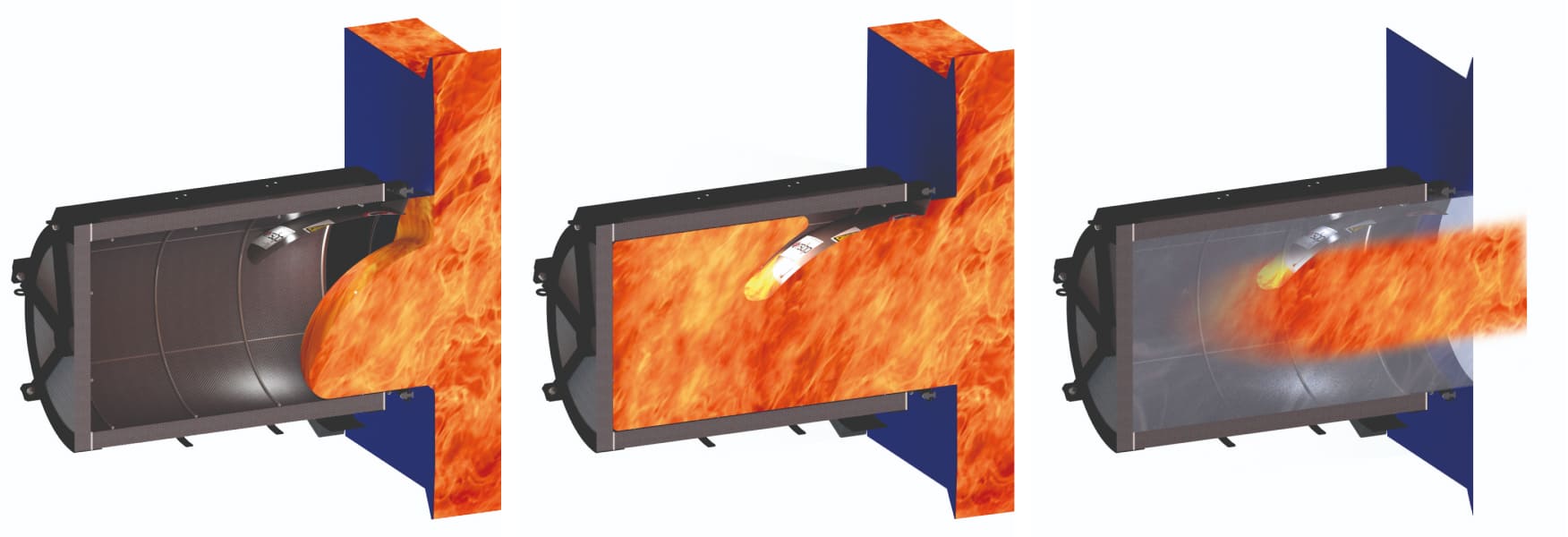

When an explosion occurs, pressure builds up in the equipment. The alarm gives a command to open the VMP explosion diaphragm. Flames, burning dust, gases are discharged into the FLEX unit.

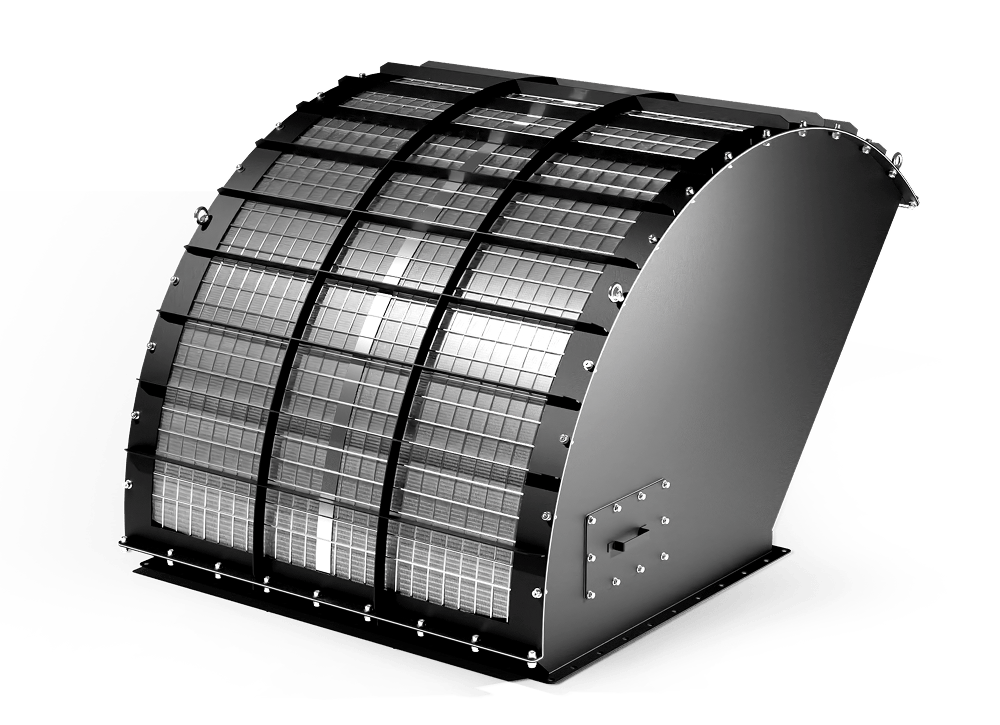

Temperatures of up to 1500°C can be reached in a normal explosion pressure release. In explosions of light metal powders, e.g. aluminium and magnesium, temperatures can be around 3000 °C.

The released explosion products pass through a system of grids in the dispersal surface where they are cooled and decelerated to safe levels.

- Provides explosion protection in enclosed areas. In the event of an accident in the equipment, there is only a slight increase in ambient temperature and pressure, which is safe for people and technical structures.

- Due to its simple design, the FLEX F is the most inexpensive flameless explosion venting device.

- It is economical in operation. Flameless explosion venting devices are designed for multiple use. After an explosion, it is sufficient to replace the cover, if used.

- Resistant to dust and mechanical damage as well as process pressure fluctuations.

- Integrates into existing equipment and automatic control system.