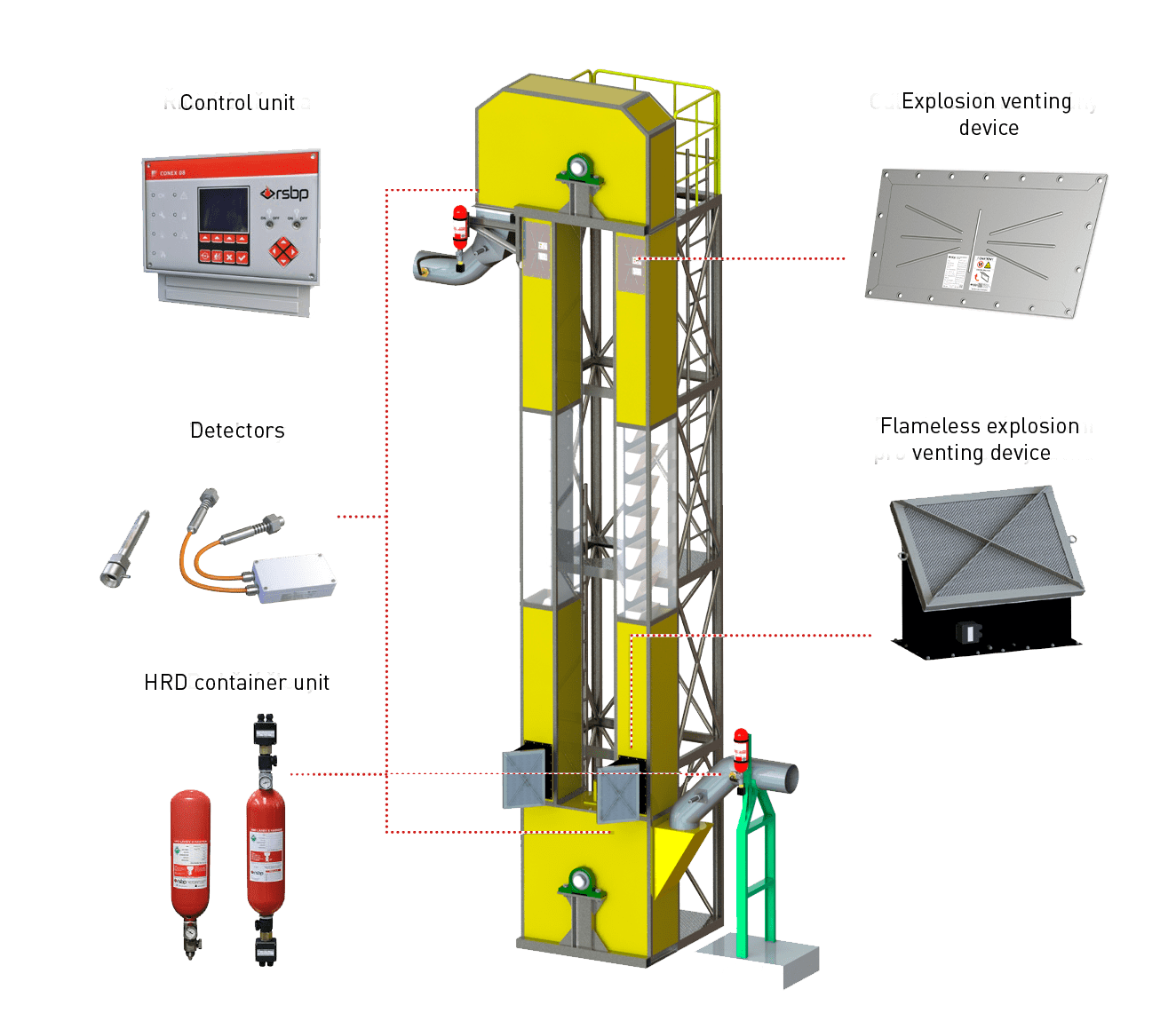

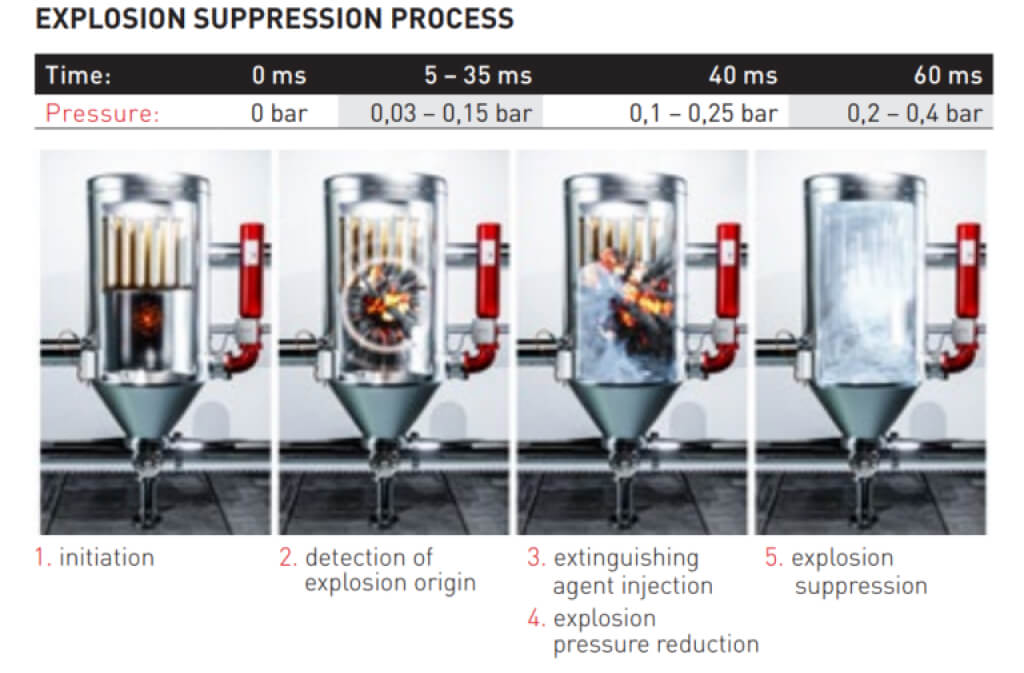

The ELEVEX explosion suppression system detects the source of danger and uses the controller to trigger the explosion suppressant containers. As a result, the primary explosion is extinguished at the nucleation stage and no secondary explosion takes place. The entire process takes no more than 60 ms.

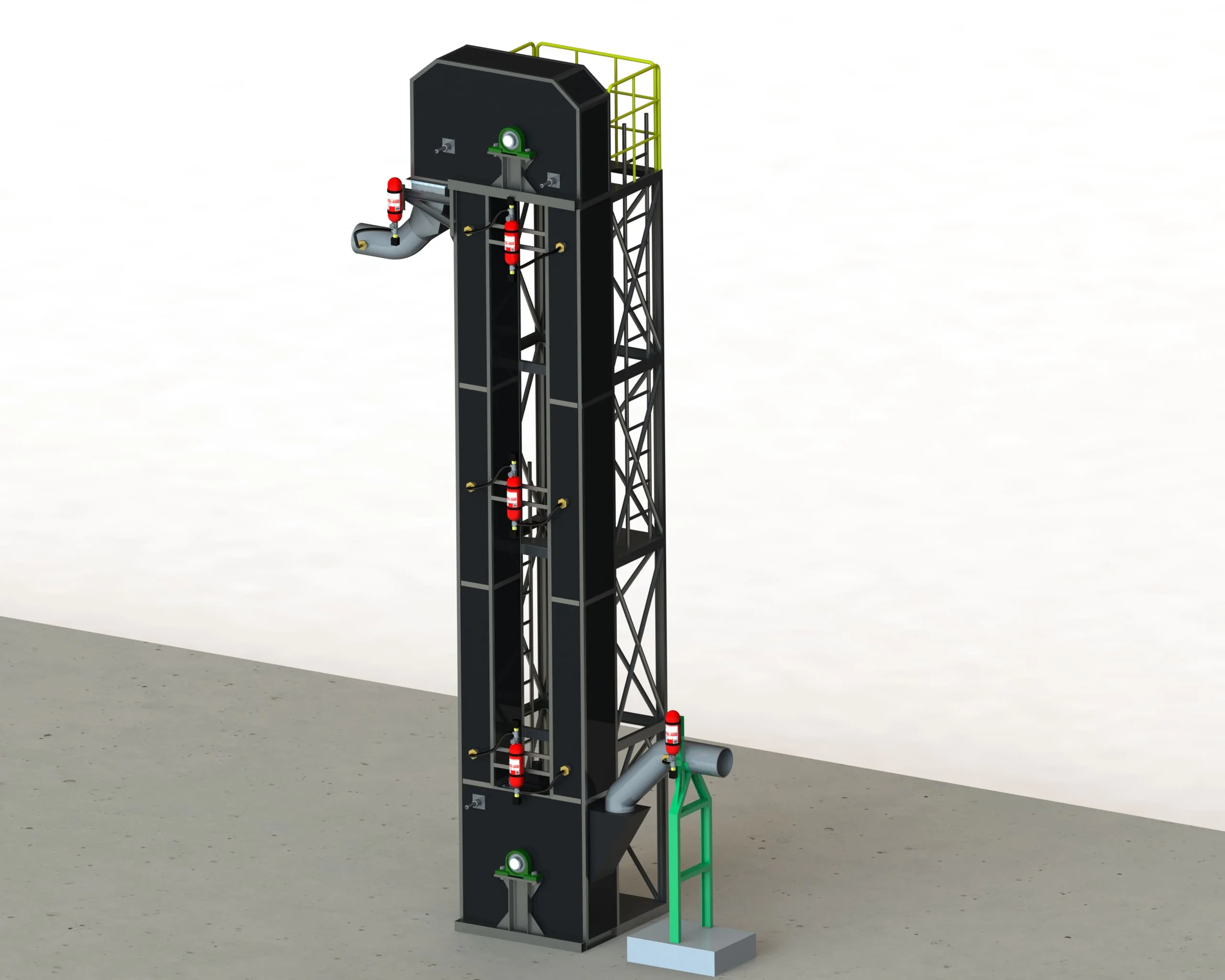

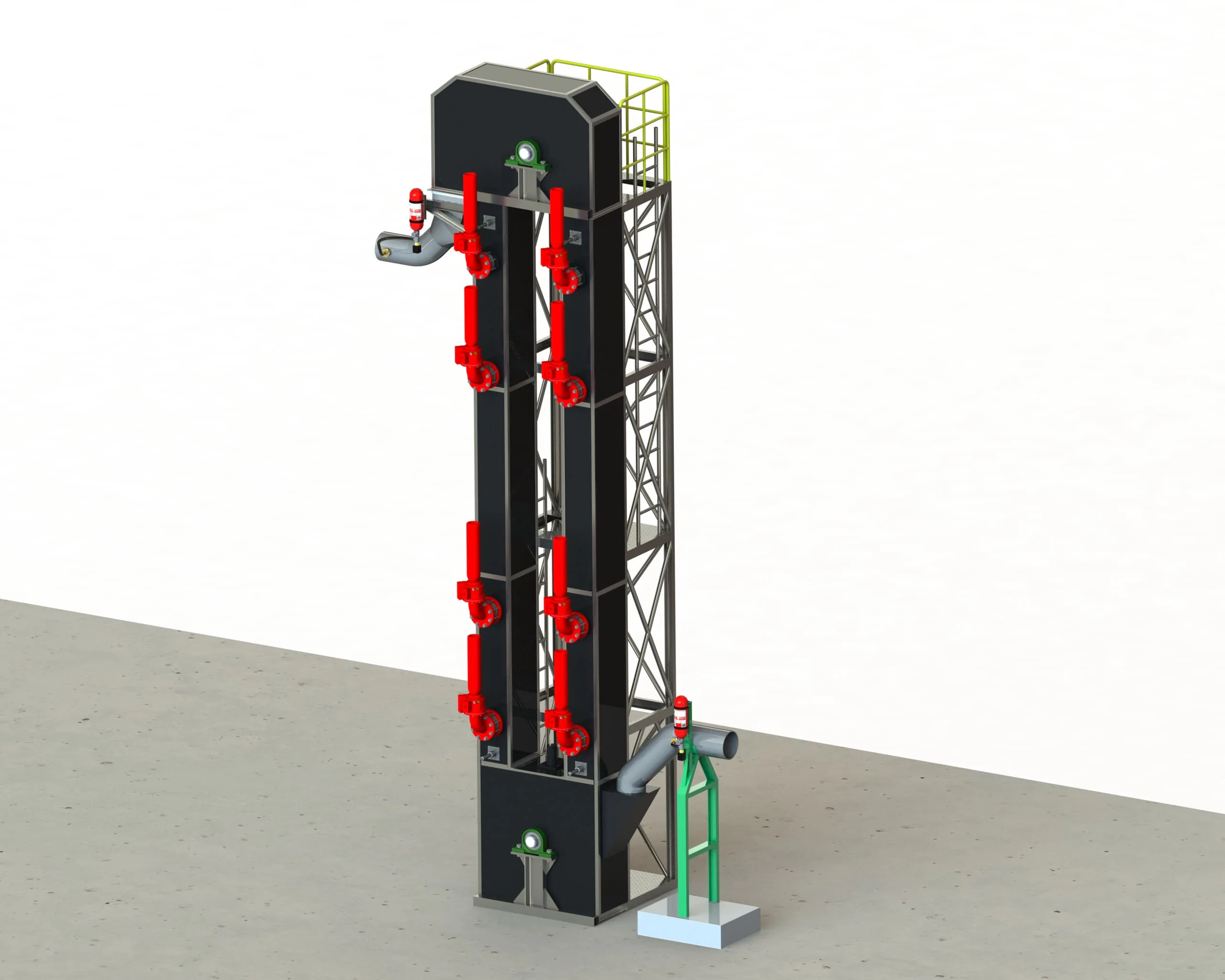

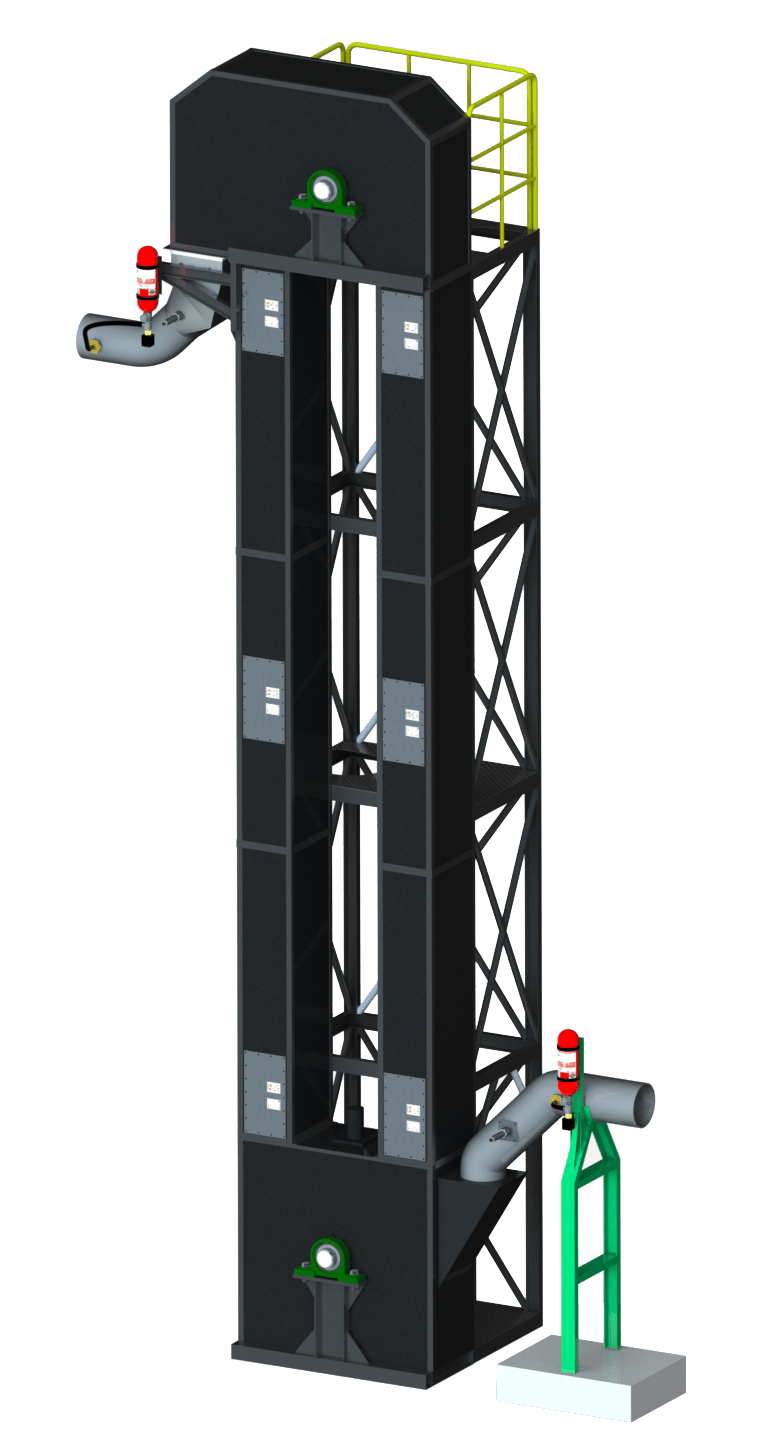

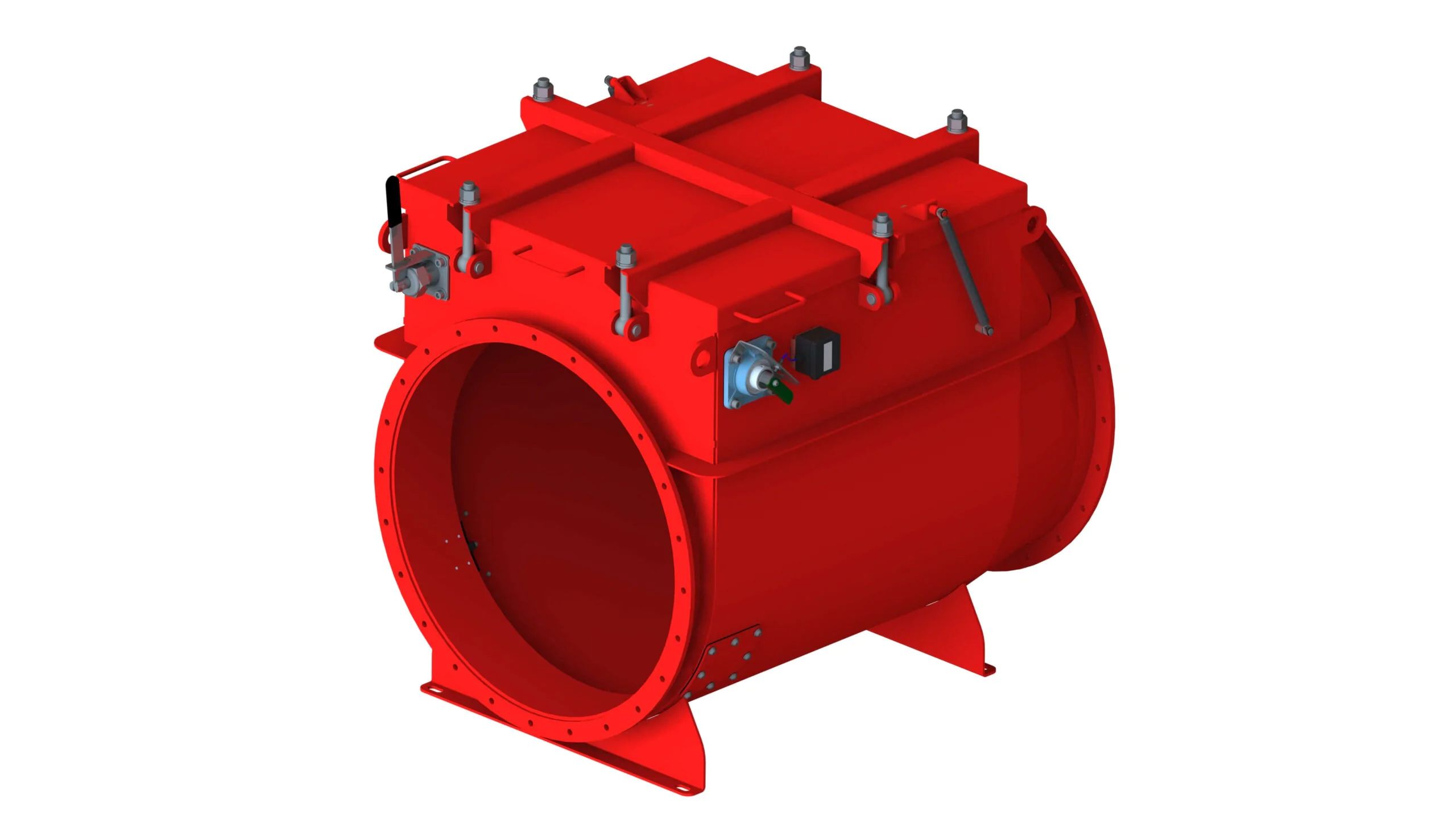

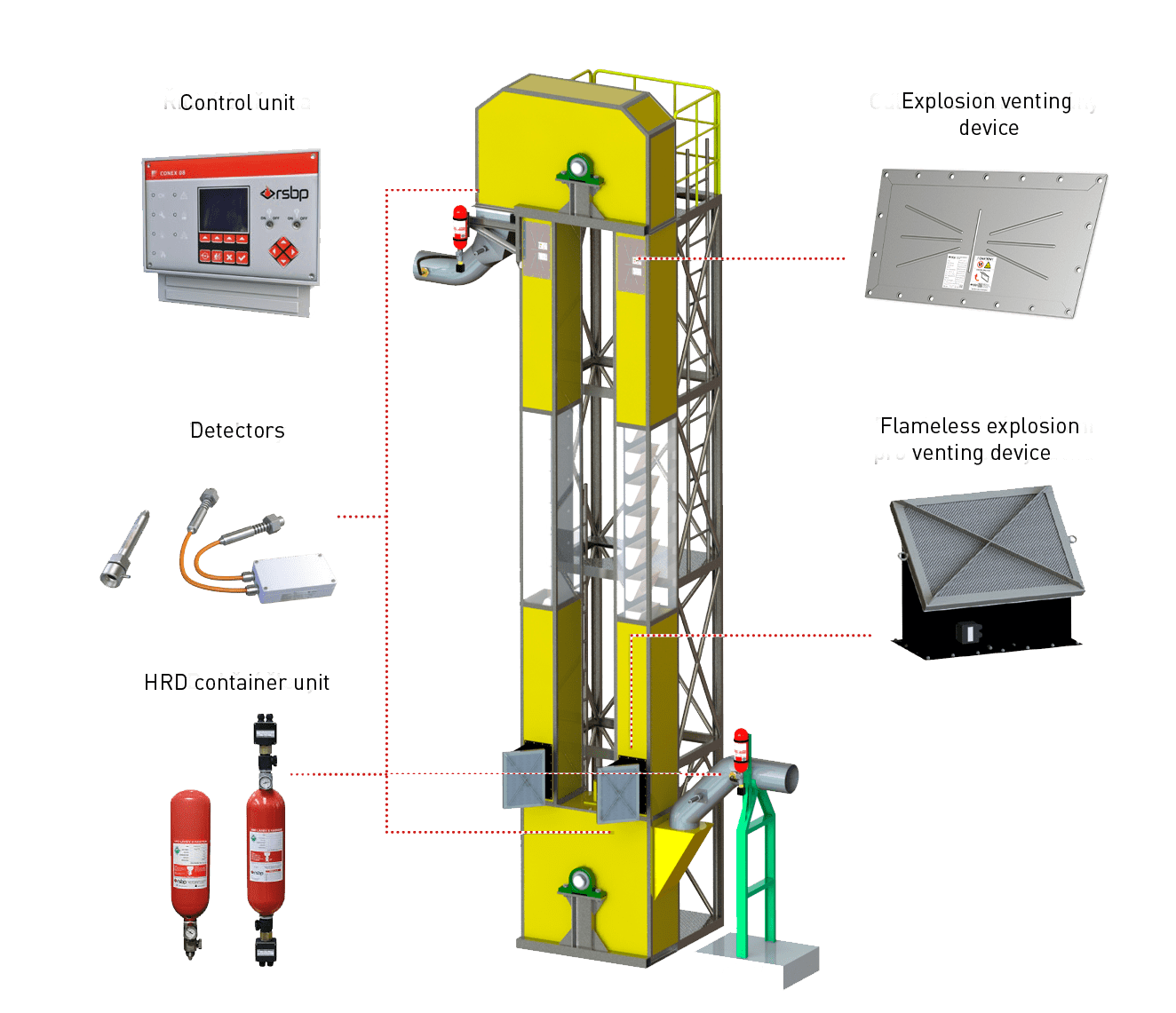

The ELEVEX system consists of explosion detectors, HRD barriers on the inlet and outlet piping, HRD system on the elevator head and elevator boot.

The principle of its elements is the same: to detect and suppress an explosion. These devices also include similar components:

- Detectors consisting of a sensor, a sensor and a contactor;

- CONEX controller;

- HRD cylinder with extinguishing agent.

The difference is that HRD barrier dampers use specially shaped nozzles which distribute the explosive powder in a fan. This captures a larger area to contain the explosion.

WATER SHOT cylinders are the same as HRD cylinders but with water. They are used where there are strict hygiene requirements and the extinguishing powder affects the quality of the final product that passes through the transport system.

- Quickly detects and suppresses an explosion – the whole process takes no longer than 60 ms.

- Dampers are easy to replace once triggered.

- No explosion products leave the elevator.

- The ELEVEX explosion suppression system is easily adaptable to the conditions of the existing process. There is no need to carry out equipment upgrades. Installation is carried out with minimal interference to the elevator devices.

- Maintenance is carried out without special tools or experts. We can provide you with clear and detailed instructions for use.

- The ELEVEX system can be used in open areas and in confined spaces.