Introduction

Preventing explosions in hazardous environments requires a carefully considered protection strategy. A key element of this strategy is the proper selection of explosion protection technologies, which must be tailored to the specific operating conditions and characteristics of the hazardous environment. This article discusses the main types of industrial explosion protection devices, the main criteria for selecting the appropriate equipment, and the steps involved in implementing explosion prevention systems in a facility.

What is an Explosion Protection System?

“Ex-protection”, or explosion protection systems, refers to a collection of engineering solutions and proactive steps undertaken to avoid or reduce the severity of incidents. These measures are essential in areas where the potential for an explosive atmosphere exists due to the presence of flammable gases, vapors, mists, or dusts in sufficient quantities.

However, it’s crucial to understand that not every type of industrial dust presents a hazard. The “explosion pentagon” visually represents the five essential elements needed for a dust burst to occur. Eliminating one or more elements from the "pentagon" prevents a blast. Protection systems are designed to do just that.

Industries where explosion protection technologies should be installed:

- Chemical industry

- Pharmaceutical industry

- Food industry (flour, sugar, grain production)

- Wood processing industry

- Energy industry (production and storage of solid fuels)

- Metallurgy (production of aluminum, magnesium and other explosive metals)

The primary purposes of Ex-protection are to:

- Explosion Prevention: Stopping explosions at the source through ignition control.

- Damage Limitation: Reducing the impact of explosions by containing their spread.

- Personnel Safety: Ensuring the well-being of workers in hazardous environments.

- Asset Protection: Minimizing damage to equipment and infrastructure, reducing financial losses.

- Regulatory Compliance: Meeting all required safety regulations and standards.

Write to us and we will advise you free of charge on all aspects of explosion protection.

Types of Explosion Protection Systems

Passive protection

Passive protection comprises structural measures that permanently and automatically provide protection against explosion without requiring activation or intervention at the time of the hazard. It is based on the properties of materials, structures and the layout of the facility.

Let's look at some examples of systems that belong to passive explosion protection:

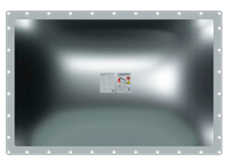

| Explosion vent panels | Explosion isolation valves |

|---|---|

| VENT PRO S | B-FLAP |

|

|

| In the event of an accident, the pressure rises and the explosion vent panel opens. The products of the explosion – flames, burning particles, blast wave – are released and discharged into the environment. | In normal operation B-FLAP is open by the RPD mechanism. In the event of an explosion, due to the air shock wave, the explosion isolation valve closes and locks in the closed position. |

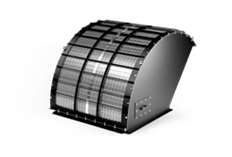

| Flameless explosion venting devices | |

| FLEX R | |

|

|

| When an explosion occurs, pressure increases in the equipment, resulting in the opening of the VMP vent panel. Flames and burning dust are discharged into the FLEX device. | |

Active protection

Active protection includes systems and devices that require activation or intervention to prevent or suppress an explosion. It is based on detecting signs of an explosion at an early stage and automatically taking measures to neutralize it.

| Explosion suppression systems | Chemical explosion isolation systems |

|---|---|

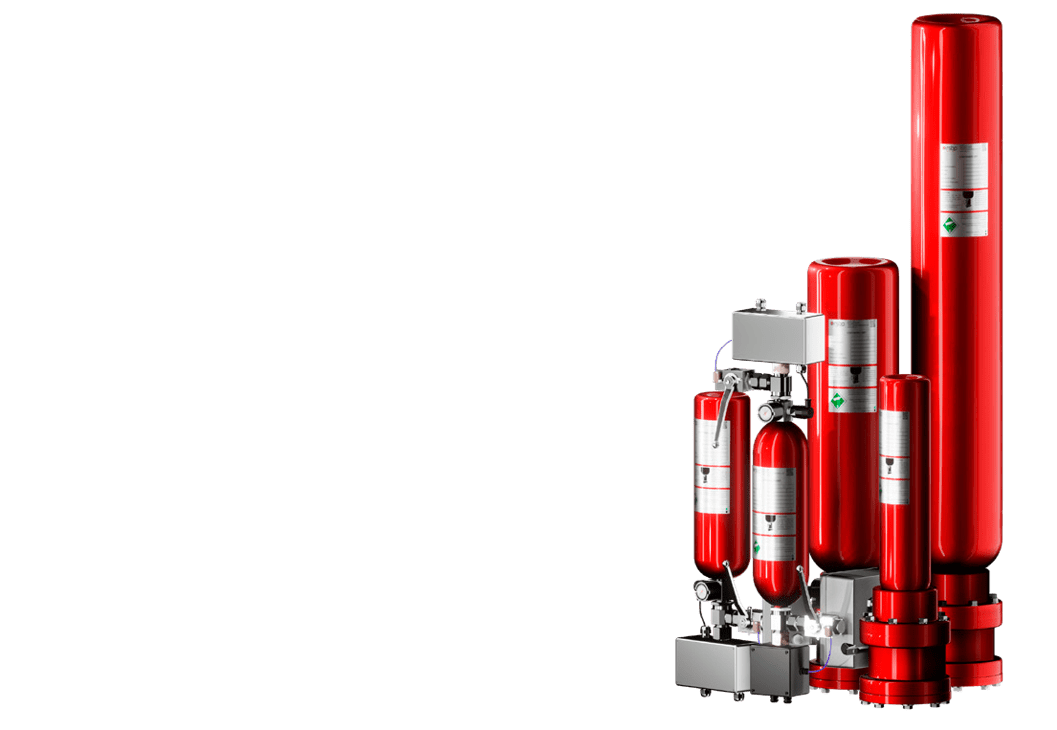

| HRD system | HRD barrier |

|

|

| HRD detects an explosion in equipment at an early stage by means of highly sensitive sensors and suppresses it effectively by applying an explosive suppressant. | HRD barrier detects the onset of an explosion and introduces an explosive suppressant into the equipment to limit the spread of the flame front to other items of process equipment. |

Passive and active explosion protection complement each other and can be used in combination to ensure the highest level of safety.

| Characterization | Passive protection | Active protection |

|---|---|---|

| Principle of action | Providing protection at all times, without activation. | Requires activation or intervention. |

| Dependence on external factors | Independent of external factors. | Depends on the performance of sensors, control systems. |

| Complexity of maintenance | Easy to maintain, mostly visual inspection. | Requires regular maintenance and inspections. |

| Cost | Usually lower than active systems. | Usually higher than passive systems. |

| Applicability | Wide range of applications. | Limited to certain types of objects and processes. |

Preventive measures

The essence of preventive measures is to actively reduce the probability of an explosion occurring. This is accomplished by eliminating or minimizing the factors necessary for a burst: combustible dust, oxidizer (oxygen) and ignition source.

- Spark Detection Systems

- Ventilation

- Dust extraction

These systems continuously monitor equipment and ductwork to detect sparks or smoldering particles before they can ignite a dust cloud. When a spark is detected, the extinguishing system is activated, quickly eliminating the potential ignition source.

Effective ventilation reduces the concentration of dust in the air, keeping it below the lower explosive limit (LEL).

Dust extraction systems collect and remove dust directly at the point of generation, preventing particles from accumulating on surfaces and in the air.

Important criteria for selecting an explosion protection system

Type of hazardous substance

Each industry sector is characterized by its own specific application of explosion protection systems. For example, rupture discs or vent panels can be installed to protect against blast of dust, gas, steam. FLEX, B-FLAP, GATEX are used for explosion protection of equipment in the presence of combustible dust in production.

Operating conditions

The selection of equipment depends on the operating conditions (temperature, pressure, humidity). For example, ventilation panels can withstand temperatures up to 240°C and are weatherproof.

Size and construction of the facility

If there is a probability of a burst in the room, it is advisable to install explosion localization and suppression devices, flameless explosion venting devices on the equipment. For equipment used outside the facility, discharge panels and flameless release devices are suitable.

Compliance with industry standards

Preventing bursts is not only an obligation, but also a key to sustainable plant operations. Compliance with ATEX, NFPA and IECEx standards is critical to protecting personnel, property and the environment. Ignoring these standards can result in financial loss, suspension of operations and, in the worst-case scenario, fatality.

Cost effectiveness and equipment costs

When selecting protection equipment, the available budget must be considered. Explosion protection panels are often seen as an economical option for protecting premises. It is important to remember that the choice between cost and effectiveness requires careful analysis.

Factors affecting the cost:

- Equipment cost.

- Installation and commissioning costs.

- Maintenance and repair costs.

- Personnel training costs.

Steps to Implement Explosion Protection

Data collection, identification of hazardous areas.

Risk assessment and classification of areas by hazard.

Preparation of a report with recommendations.

Selection of passive and/or active safety measures.

Selection of technical solutions (equipment, standards).

Consideration of budget and operating costs.

Preparation of terms of reference.

Development of project documentation.

Performing equipment installation.

Carrying out systems integration.

Performing commissioning and acceptance testing.

Conducting personnel training (briefings, examinations).

Conducting certification.

Ensuring regular professional development.

Carrying out maintenance in accordance with the schedule.

Carrying out monitoring of the system status.

Maintenance of documentation.

Analyzing emergency situations.

Conducting periodic reassessment of risks.

Conclusion

Explosion safety requires a professional approach. Selecting the optimal explosion protection system is a task that requires in-depth knowledge and experience. Wrong decisions can lead to financial losses and threat to life. To guarantee the safety of your company we recommend ordering an audit and consultation with ATEX.CENTER specialists. We will conduct a comprehensive risk assessment, select equipment that meets international standards, install and provide service.