Facilities that produce substantial amounts of dust rely on industrial dust collectors to ensure a healthy environment and meet regulatory standards. However, it’s essential to recognize that dust collectors can pose a risk of explosion. We will reveal when filtration systems become dangerous and how to protect your company from accidents.

Understanding the Risk of Dust Collector Explosions

What is a Dust Collector?

A dust collector is a device designed to remove particulate matter from the air. Its primary function is to improve air quality by capturing and separating dust and other solid particles from the air stream, leading to a cleaner working environment. Dust collectors play a crucial role in minimising explosion risks, maintaining equipment efficiency, and ensuring compliance with OSHA and NFPA safety standards.

What Causes Dust Collector Explosions?

Dust collector explosions are caused by a combination of factors that together create a dangerous situation.

- Combustible dust. Easily ignitable fine material.

- Dispersion. Air, carrying particles, contains enough suspended dust to form a combustible cloud.

- Oxygen. The presence of oxidizer.

- Confinement space. The closed, limited area inside the collector promotes a rise in pressure.

- Ignition Source.

When these five factors coincide within a filtration system, a rapid deflagration can occur, quickly escalating into a destructive detonation due to the confined space.

Common Ignition Sources

An ignition source provides the energy needed to start the combustion process. There are some common ignition sources:

- Mechanical Sparks. Generated by friction, impact (e.g., metal striking metal), or malfunctioning equipment.

- Electrical Sparks. Caused by faulty wiring, short circuits, static electricity, or improper grounding.

- Hot Surfaces. Overheated parts of equipment can provide enough heat for ignition.

- Flames: Welding, cutting, or other open flames.

- Electrostatic Discharge (ESD): The presence of static electricity can create sparks, particularly with non-conductive materials.

Real Incidents:

India, 2024. The blast at the auto parts factory in Rewari, which killed at least 11 people, occurred in the dust collector because it hadn't been cleaned in years.

Japan, 2025. One person was killed and two others slightly injured due to a dust collector explosion at a Toyota contractor's factory.

The USA, 2022. Employees were cleaning up tools after repairing the baghouse dust collector at Buchanan Lumber Company. When they turned the equipment on for a test run, it exploded.

Types of Industrial Dust Collectors and Their Hazards

Types of Industrial Dust Collectors

There is a wide range of dust collection systems:

|

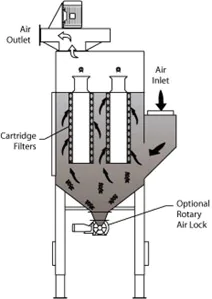

Cartridge collectors  These systems utilize pleated filter cartridges, often cleaned by pulse-jet technology, to effectively capture fine dusts. Cartridge collectors are known for their compact design and relatively simple maintenance. |

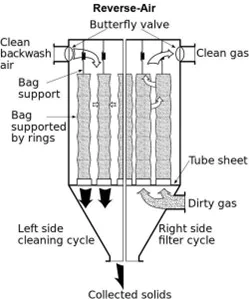

Baghouse collectors  These rely on fabric filter bags to trap particulate matter. |

|

Cyclone collectors  Employing centrifugal force, cyclone collectors separate dust from the air, making them particularly effective for removing larger particles. |

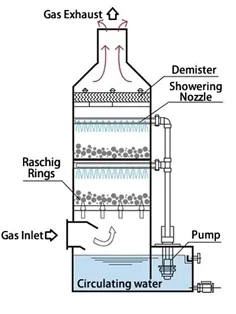

Wet scrubbers

Using liquid to capture dust, wet scrubbers excel at controlling sticky, corrosive, or explosive particles. |

Which Dusts Are Combustible?

Many types of shredded materials, when dispersed in the air, can become explosive. Here are some common categories and examples of combustible dusts:

- Metals: aluminum, magnesium, titanium, iron, zinc.

- Organic materials: wood, grain, flour, sugar, soybeans, powdered milk, coal.

- Plastics: acrylic, phenolic resins, polyester, polyethylene.

- Chemicals: dyes, sulfur, pharmaceutical ingredients.

Materials That Pose Higher Risks

Although all combustible dusts pose a risk, certain materials are significantly more hazardous than others due to their increased ease of ignition, explosiveness, and potential for rapid flame propagation. This is especially true for metals. The following are some of the most dangerous materials.

- Aluminum and magnesium. It has a minor lower explosive limit (LEL) and a high explosion severity (Kst), leading to powerful and destructive explosions.

- Titanium. It is easily ignited and burns with a very high flame temperature.

- Zirconium. It is highly reactive and pyrophoric, meaning it can spontaneously ignite in air.

Understanding which dusts are combustible is critical for selecting the right dust collection system, applying proper explosion protection measures, and complying with OSHA/NFPA standards to ensure workplace safety.

Importance of Dust Collection System Risk Assessments

What is a Dust Collection System Risk Assessment?

A Dust Collector System Risk Assessment is a thorough process of identifying potential dangers within a dust collection system, such as fires or explosions. By analyzing the probability and potential impact of these hazards, it allows for the development and implementation of control measures designed to minimize risk and create a safer working environment.

Who Should Perform It?

A Dust Collection System Risk Assessment should be conducted by a qualified and experienced team. Qualified personnel specialized knowledge. Consultants provide objective assessments, expertise on best practices, and help ensure regulatory compliance.

How to Conduct a Proper Risk Assessment

On your own at your facility, you can reveal areas where excessive dust accumulates; identify potential sources of fire and provide training to employees.

Dust Collectors for Combustible Dust

Key Design Features

There are the features specific to combustible dust collectors, emphasizing safety and explosion prevention:

- Non-Sparking construction. All internal parts contacting dust are non-sparking materials (aluminum, brass, stainless steel).

- Grounding & bonding. Thorough grounding and bonding to prevent static electricity buildup.

- Explosion protection. Protection of equipment against dust explosion.

- Deflagration-resistant construction. Heavy-duty construction to withstand potential deflagrations.

- Appropriate filtration. Filter media compatible with dust and electrostatic dissipation.

- Airtight discharge. Sealed dust discharge mechanisms (rotary airlocks, etc.) to prevent dust cloud release.

- Temperature monitoring. Internal temperature sensors to detect overheating.

- Compliance with safety standards. Safety regulations are mandatory for each facility.

- Regular inspection. Easy access points for inspections and maintenance to ensure ongoing safety and efficiency.

Certification and Safety Ratings

The dust collector for combustible materials should be designed, manufactured, and installed in compliance with relevant standards, particularly: National Fire Protection Association (NFPA), Occupational Safety and Health Administration (OSHA), ATEX Certification (for Europe ATEX Directive 2014/34/EU).

Explosion Protection Devices for Dust Collectors

The accumulation of potentially explosive dust within dust collectors requires the utilization of explosion-protected equipment to prevent dangerous incidents. Therefore, protective devices are installed on ductwork, pipelines and dust collectors to mitigate these risks.

|

Explosion relief panels |

Valves |

|

In the event of an accident, the pressure rises and the explosion vent panel opens. The products of the explosion – flames, burning particles, blast wave – are released and discharged into the environment. |

B-FLAP EXPLOSION ISOLATION VALVE In normal operation B-FLAP is open by the RPD mechanism. In the event of an explosion, due to the air shock wave, the explosion isolation valve closes and locks in the closed position. |

|

Flameless venting devices |

Suppression systems |

|

When an explosion occurs, pressure increases in the equipment, resulting in the opening of the VMP vent panel. Flames and burning dust are discharged into the FLEX device. |

HRD detects an explosion in equipment at an early stage by means of highly sensitive sensors and suppresses it effectively by applying an explosive suppressant. |

Learn more about solutions for protecting aspiration systems

Prevention Measures for Dust Collectors

Prevention measures are crucial for minimizing the risk of fires and dust collector explosions. A multi-layered approach is essential, encompassing:

- Engineering controls: regular inspections, filter changes and explosion systems service.

- Administrative procedures: emergency plans for fires, explosions, and evacuations. Housekeeping and cleaning. Safety procedures.

- Personnel training: employee education on hazards.

Conclusion

Properly designed and maintained dust collection systems with appropriate explosion protection are essential for preventing catastrophic incidents. It’s important to work with qualified professionals to assess your specific dust hazards and design the most effective explosion protection system for your dust collection equipment. Don’t gamble with safety – protect your people, property, and business by prioritizing dust collector explosion protection.