Statistically, elevator explosions account for almost a third (27%) of all accidents occurring each year at crop processing and storage facilities. They are the most destructive of these accidents. Elevators account for 45% of the worst accidents.

This is because a flour dust explosion in an elevator, as a rule, does not occur alone. It is caused by a dangerous concentration of combustible dust/air mixtures in a confined space of the equipment. The initial ignition of the dust/air mixture leads to a series of explosions, killing people and destroying the facility.

Vertical bulk material handling systems, due to their design features, create the ideal environment for an explosion. They contain an enclosed volume, a combustible dust/air mixture and an initiation source:

- Sparks from a collision between the ladle and the housing;

- Heated surfaces;

- Sparks from the electric motor;

- Overheated bearings;

- Smouldering particles from the transport system.

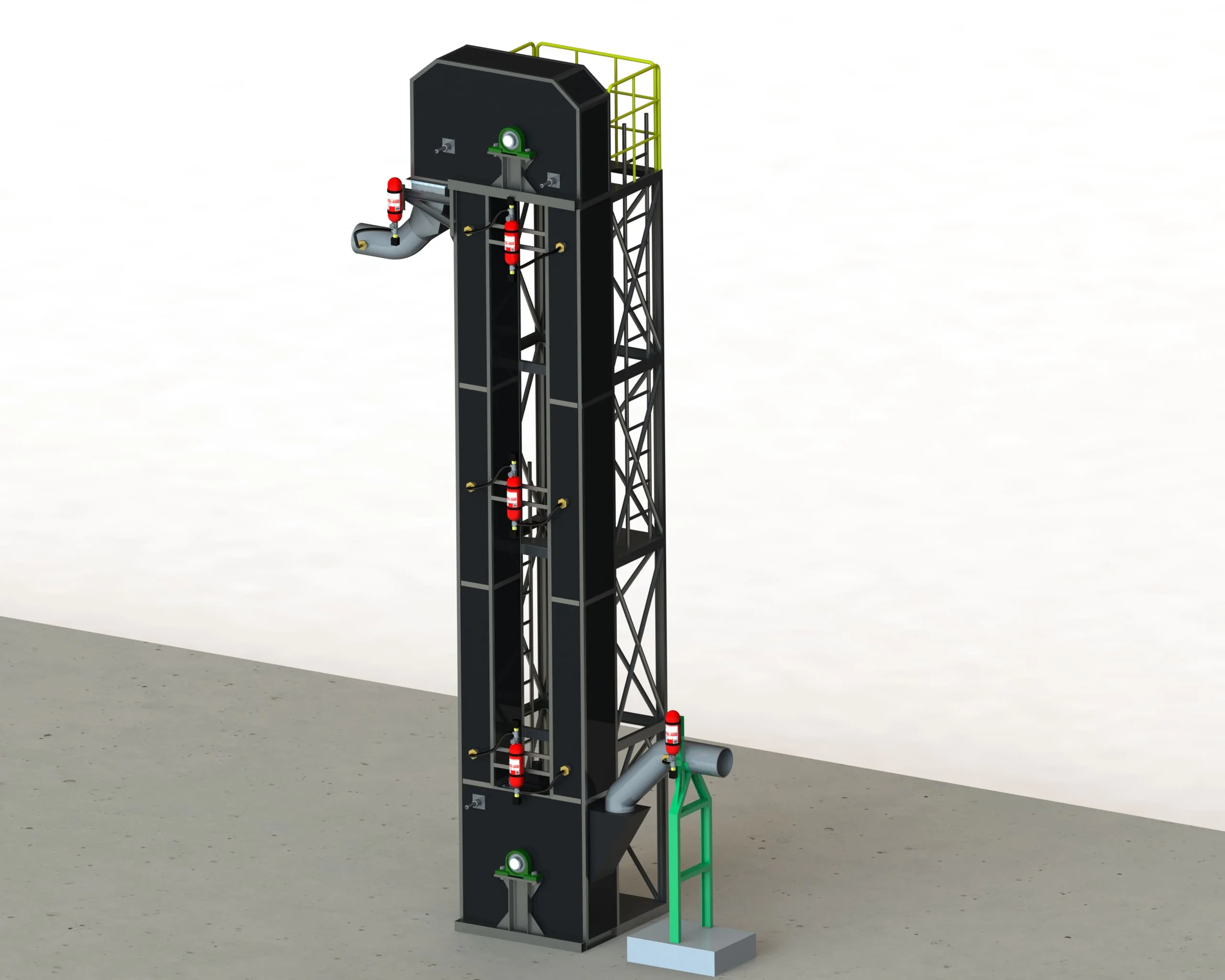

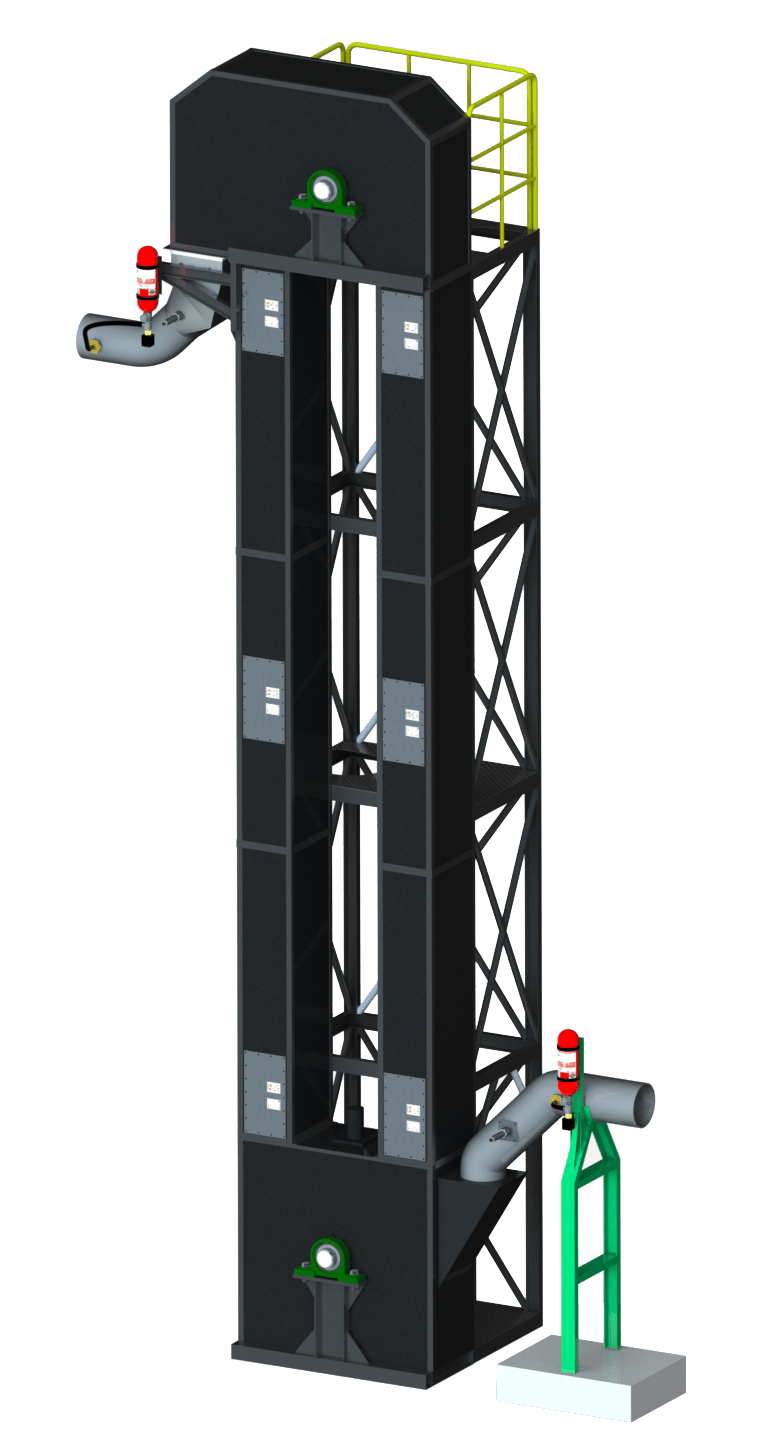

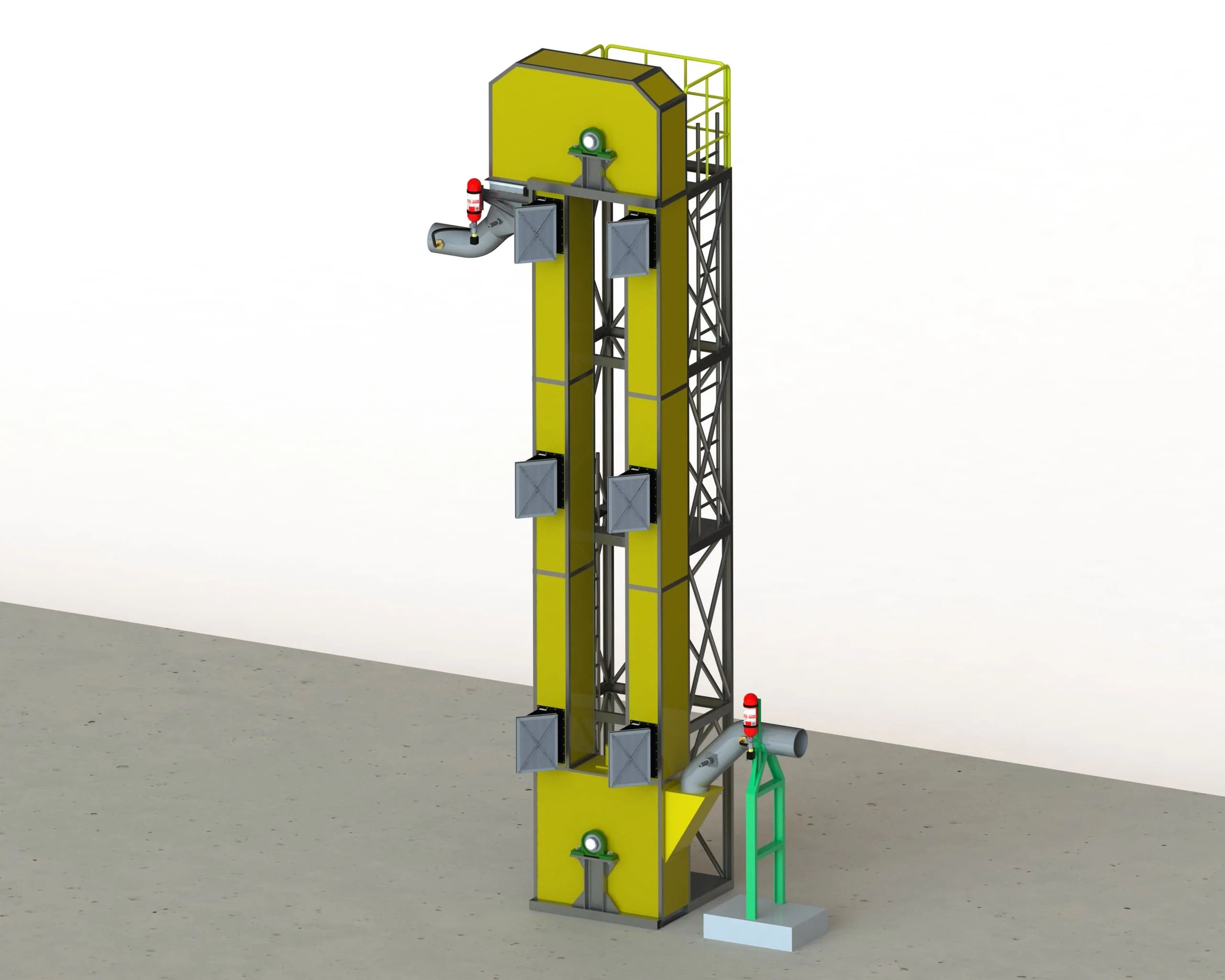

It is not possible to completely rule out the possibility of an accident at bucket elevators. This is why devices are used that minimise the destructive effects of an explosion. ELEVEX systems, for example, are used.

The principle of the operation is to reduce the overpressure of the blast wave and to protect people and equipment from open flames. This ensures the safety of personnel and the safety of the production facility.

ATEX explosion protection standards stipulate that explosion suppression or exemption systems must be installed on storage and processing equipment. Where people are working and the fire safety of the elevator must be ensured, flame arresters are used.

ATEX.CENTER explosion protection solutions across various industries, ensuring safety and continuity. From Explosion protection for energy production facilities and Explosion protection for chemical and pharmaceutical production, for Explosion protection for foodstuffs, Explosion protection for metalworking industries, wood processing, and agricultural sectors, our expertise secures your operations against potential hazards, guaranteeing peace of mind and uninterrupted productivity.