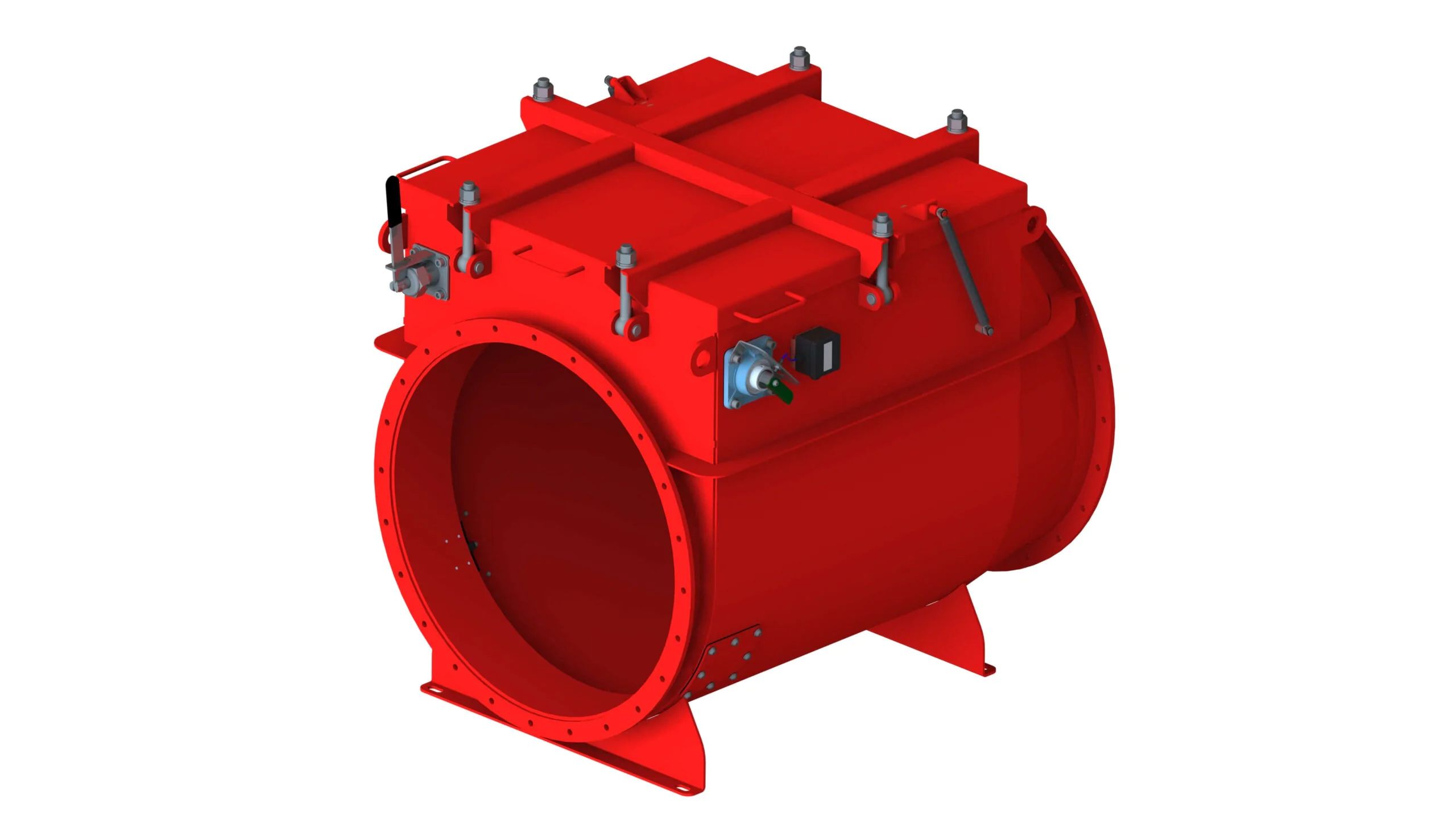

The EX DOOR explosion-proof panel is a galvanised steel magnetic construction, designed for repeated use. It can be equipped with a seal to ensure dust-tightness and an open/close indicator.

The blast panel is suitable for process equipment with a low operating pressure, up to 0.7 bar, and which is not resistant to pressure rises. It opens at 0.1 bar as standard, but can be adjusted to the customer’s process conditions. The blast door is not used where pressure surges can occur.

- The panel activates on pressure rises up to 0.1 bar, so it can be used on pressure-sensitive equipment. The explosion plate can be adapted to the specific process equipment.

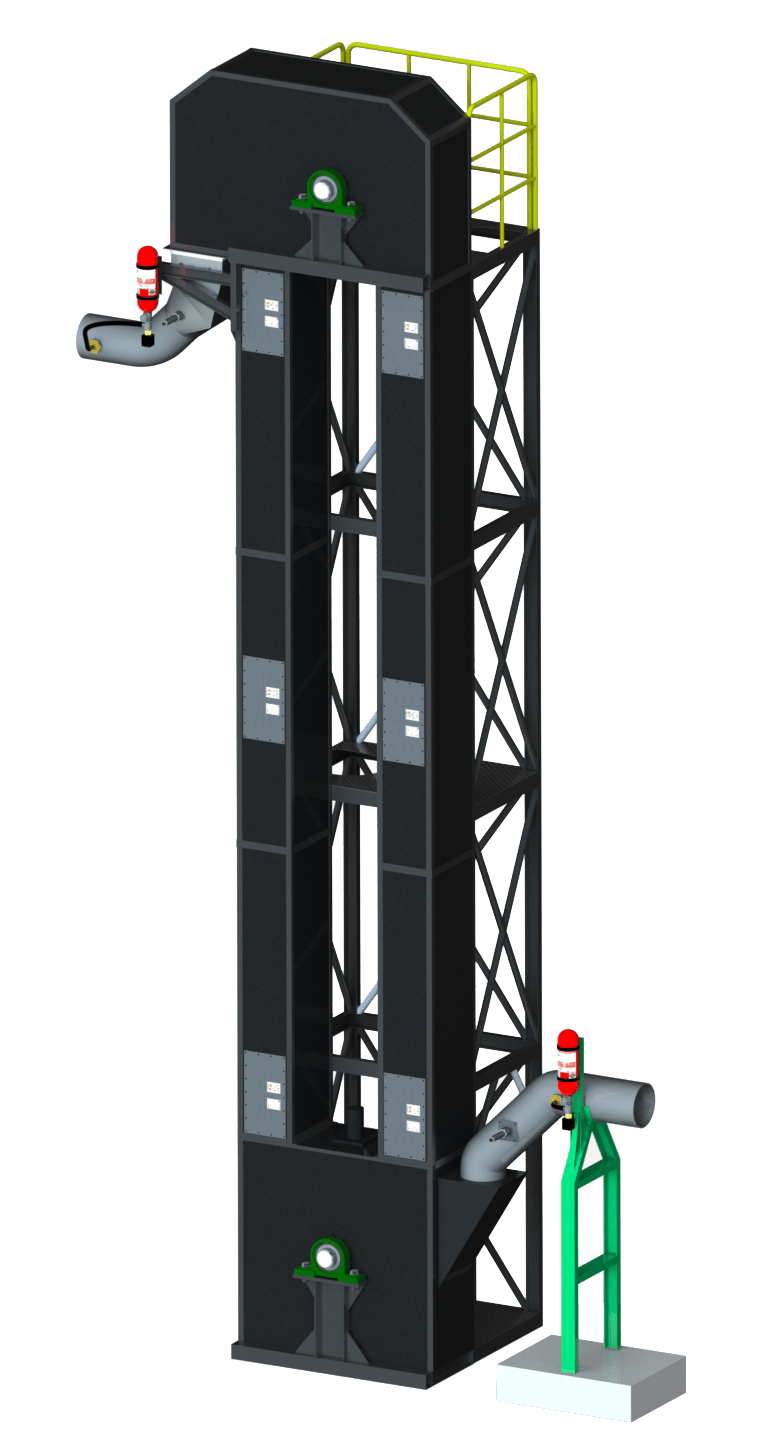

- Easy to assemble – assembly in only two steps, according to ready-made drawing kits and assembly instructions.

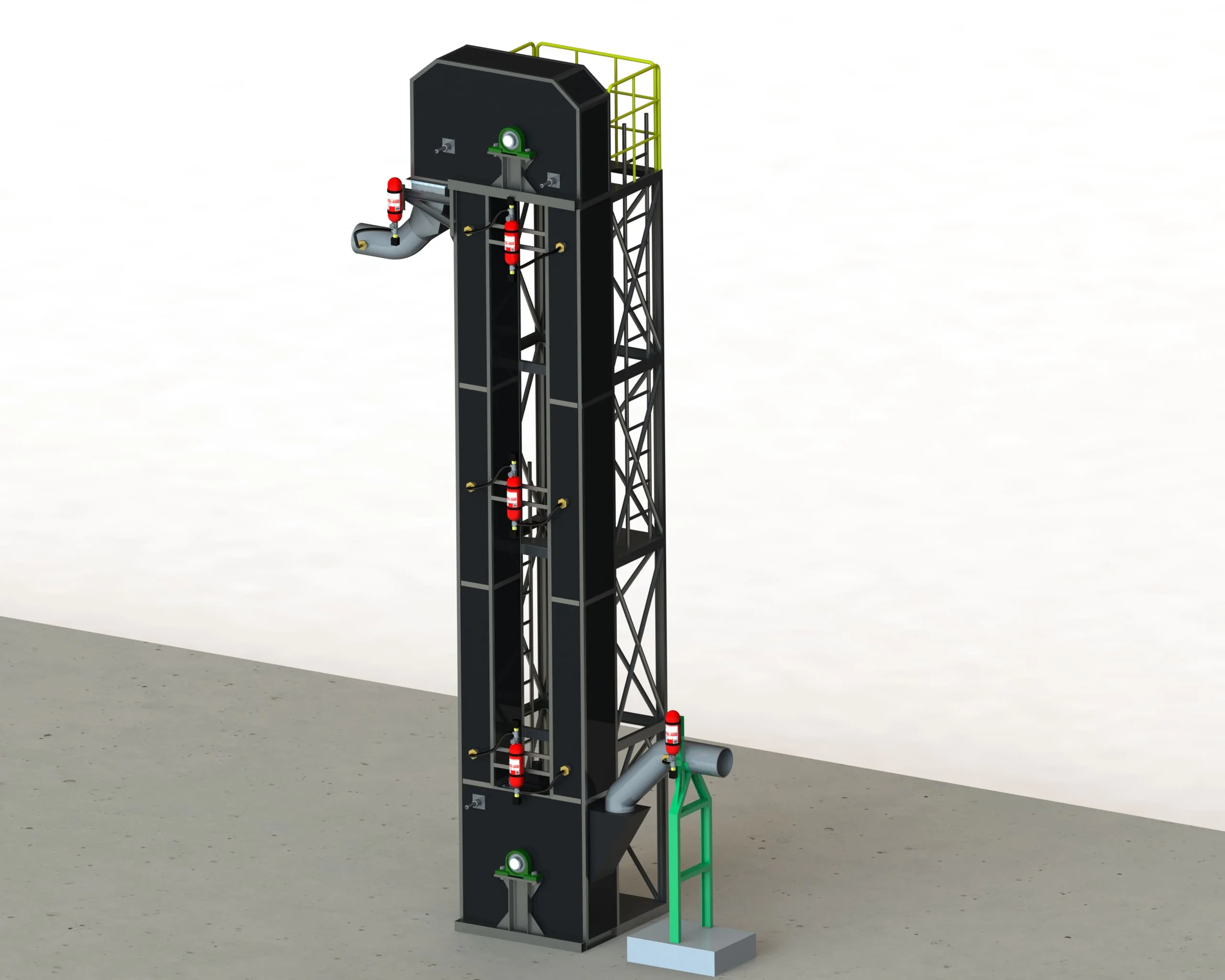

- Easy to maintain – we will provide a detailed operating manual, which describes the frequency of all operations. The customer’s employees are only required to visually inspect the cleanliness and integrity of the blast panel.

- Installed without altering the design of the existing process equipment.

- Reusable, so there is no cost for consumables and accessories.

- Service is only required once a year, which also reduces operating costs.