Danger of tanks explosion

Every year, 400-500 explosions occur at plant storage and processing facilities worldwide, including food processing plants. And about half of the explosions involve various containers: silos, bunkers, containers.

The danger is due to the characteristics of the technological process:

- The presence of a combustible dust/air mixture;

- An explosion source in the tank due to self-heating and self-ignition of product mounds;

- Release of flammable gases during fermentation of raw materials due to high humidity.

Prolonged storage of self-heating products in containers leads to self-ignition. In this case, combustible gaseous products of the thermo-oxidative reaction in dangerous concentrations such as hydrogen, methane and carbon monoxide enter the overhead and underfloor spaces as well as the overhead and underfloor spaces.

Also in the process of transporting loose raw materials fine organic dust is generated: grain dust, flour dust, sugar dust, coal dust, etc. It is flammable and in contact with air forms an explosive dust/air mixture. Visually, it may not be noticeable. On contact with an ignition source, however, the dust ignites with detonation.

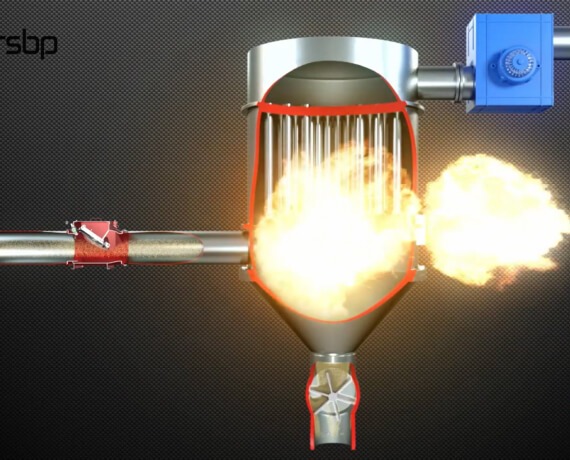

A primary explosion initiates the flame propagation to the unburned part of the dust/air/dust mixture in an enclosed space and a series of secondary explosions follow. The entire accident process is rapid and, without the use of special explosion protection systems, virtually impossible to contain. Explosive combustion of the gas-dust-air mixture in an enclosed space raises the pressure to 700-900 kPa, which exceeds the values safe for the equipment.

Sources of ignition initiation

EN 1127-1-2014 classifies 13 active ignition sources which, in contact with a combustible dust/air mixture, may lead to an accident.

What hazards may be present in the tanks

- spontaneous combustion (burning, smouldering) of bulk products;

- heated surfaces due to lack of insulation;

- unloading of burning product from silos and hoppers leading to a fire in the underlying floor;

- mechanical and electrical sparks;

- static electricity;

Silo and silo regulations stipulate that accumulations of dust, prolonged storage of plant material and temperature and humidity must be avoided. Preventive measures reduce the risk of explosion, but do not eliminate it completely. If the operating rules are not observed, the risk of explosion multiply.

Safety standards for the owner of a hazardous industrial facility

Silos and hoppers are classified as hazardous objects due to the presence of hazards. The minimum requirements for their explosion protection are specified in Directive 99/92/EC.

When operating hazardous facilities, it is necessary to:

- Assess the risks taking into account the likelihood of explosive atmospheres;

- Classify and mark hazardous areas with combustible dusts;

- Install explosion protection devices for the equipment.

Technical solutions

The safety of the tank is ensured in three ways:

- Observance of silos and hoppers operation rules, rules for storage of plant material.

- The use of modern aspiration systems.

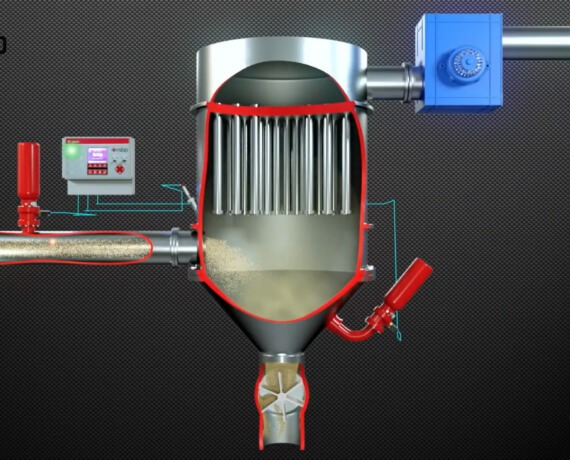

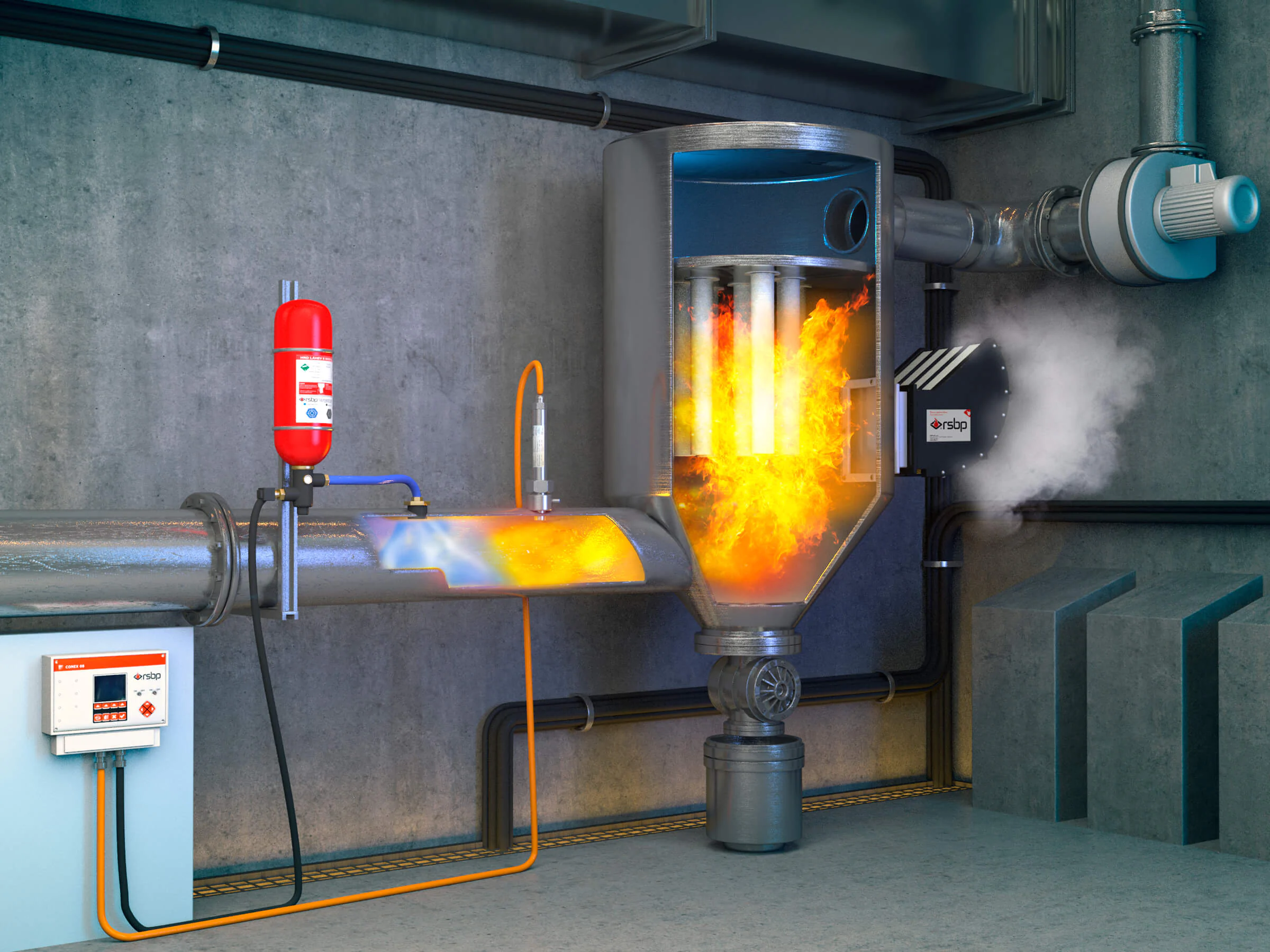

- Installation of systems for containment, cutting off an explosion and (or) safe release of an explosion — explosion dischargers..

Explosion protection systems are selected on the basis of the operating conditions and the nature of the raw materials stored in the tank. We therefore first carry out a risk analysis to determine the hazardous area classification and the level of protection in accordance with IEC 60079-10-2-2011.

For this purpose, we take combustible dusts for laboratory tests under "controlled explosion conditions". As a result, we determine the explosion hazard parameters of the production facility:

- Low Explosion Level / LEL

- Maximum rate of explosion pressure rise / (dp/dt)max

- explosion class / Kst

- Minimum explosion temperature / MIT

- Minimum ignition temperature / GT

- Minimum explosion energy / MIE

- Oxygen concentration limit / LOC

Based on this data, we select specific explosion protection equipment.

In cooperation with RSBP, we offer standard technical solutions for tank protection: explosion suppression, overpressure relief and flameless explosion release. We adapt them individually to the customer's site.