Some types of pharmaceutical dust are harmful to human health and extremely explosive. Special attention is therefore given to ventilation and aspiration systems in chemical and pharmaceutical production facilities. These systems must fully comply with good manufacturing practices and be equipped with devices to prevent explosions and fires.

Also a significant factor in deciding whether or not to implement an explosion protection system (in addition to the safety of employees and equipment) is the safety of raw materials, which can have a very high value in this industry.

Our ATEX expertise, together with the many years of experience of our European partners, enables us to offer you explosion protection products and solutions that comply with best practice in ensuring occupational health and safety, taking into account all the particularities of the chemical and pharmaceutical industries.

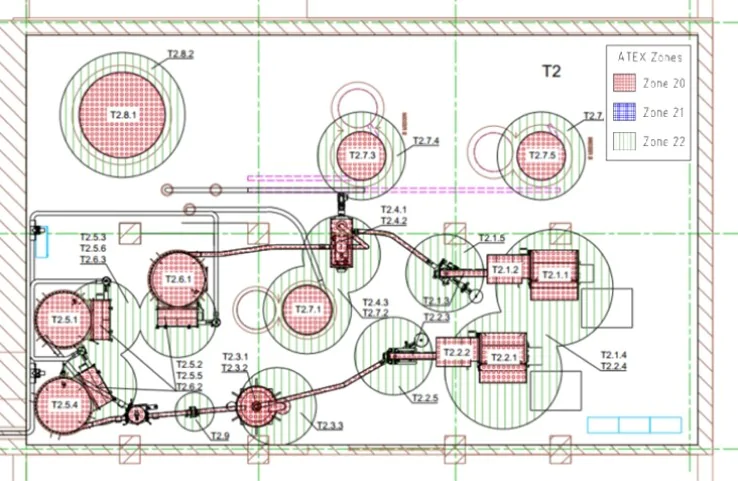

Our team has successful experience of explosion protection for tanks, aspiration and pneumatic conveying systems in production facilities. You can find out more about our projects in the PROJECTS section.

Ensure the safety of your enterprise with ATEX.CENTER, your trusted partner in explosion protection solutions. From explosion isolation valves to Flameless explosion venting devices flex, we offer a comprehensive range of products designed to safeguard your operations.

Our lineup includes top-of-the-line explosion venting panels, HRD explosion suppression systems, and the innovative System HRD. With our cutting-edge technology and expertise, you can mitigate the risk of explosions effectively.

Don't compromise on safety. Choose ATEX.CENTER for reliable explosion protection solutions that prioritize the well-being of your facility and personnel. Contact us today to learn more.