WHAT ARE THE BENEFITS OF EXPLOSION PROTECTION?

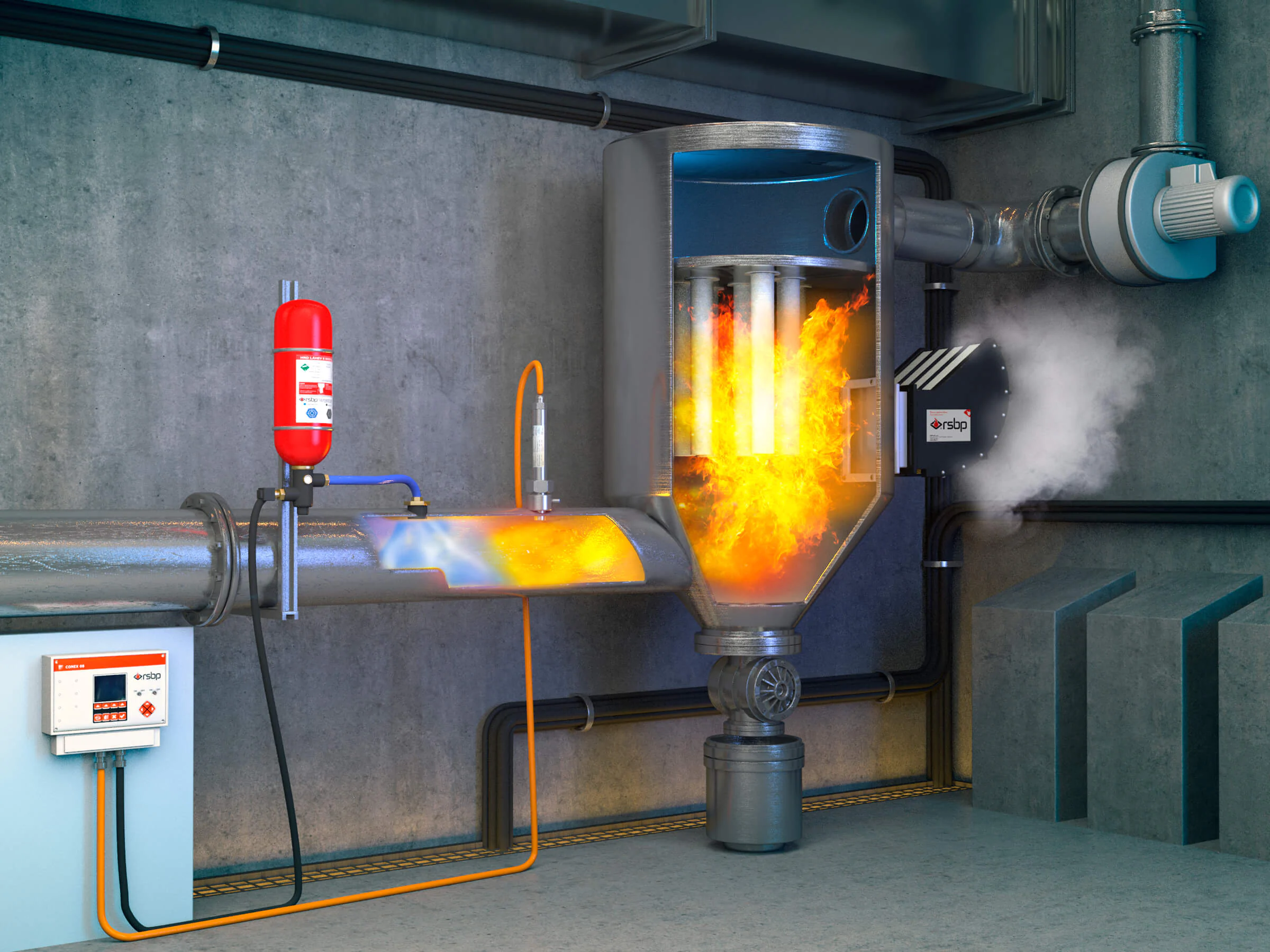

Combustible dust is a by-product of the production and transport of certain products. It is generated in places where there are wood and metal working, working with raw materials, bulk products.

Combined with oxygen, combustible dust forms an explosive and flammable mixture which causes an explosion when it comes into contact with an ignition source. One of the tasks of the operating organization is to minimise the impact of this hazard.

The formation of combustible dusts cannot be completely eliminated. Neither can all possible sources of explosion initiation - e.g. sparks, heated surfaces - be eliminated from production.

Ensuring explosion protection is one of the industrial safety responsibilities of the owner of a hazardous industrial facility.

The customer will get a fire protection and explosion protection system at the plant, adapted to the specific production conditions. He will be assured that the equipment supplier will not disappear after payment, the installation and commissioning will ensure safe operation, and the design solutions comply with regulatory requirements:

- ATEX 153 (directive 99/92/EC) - establishes the employer's obligations for explosion and fire protection in the workplace for the safety of persons;

- ATEX 114 (2014/34/EU) - contains requirements for equipment for use in potentially explosive atmospheres;

- EN 1127-1:2007 - requires the use of explosion protection systems in production facilities;

- ТР ТС 012 / 2011 - establishes safety requirements for equipment in explosive atmospheres in the countries of the Eurasian Economic Union.

The customer will not have to spend time researching legislation and looking for contractors on their own. He will get European explosion protection solutions for his company all in one place.