WHY PRODUCTION DUST TESTING SHOULD BE DONE

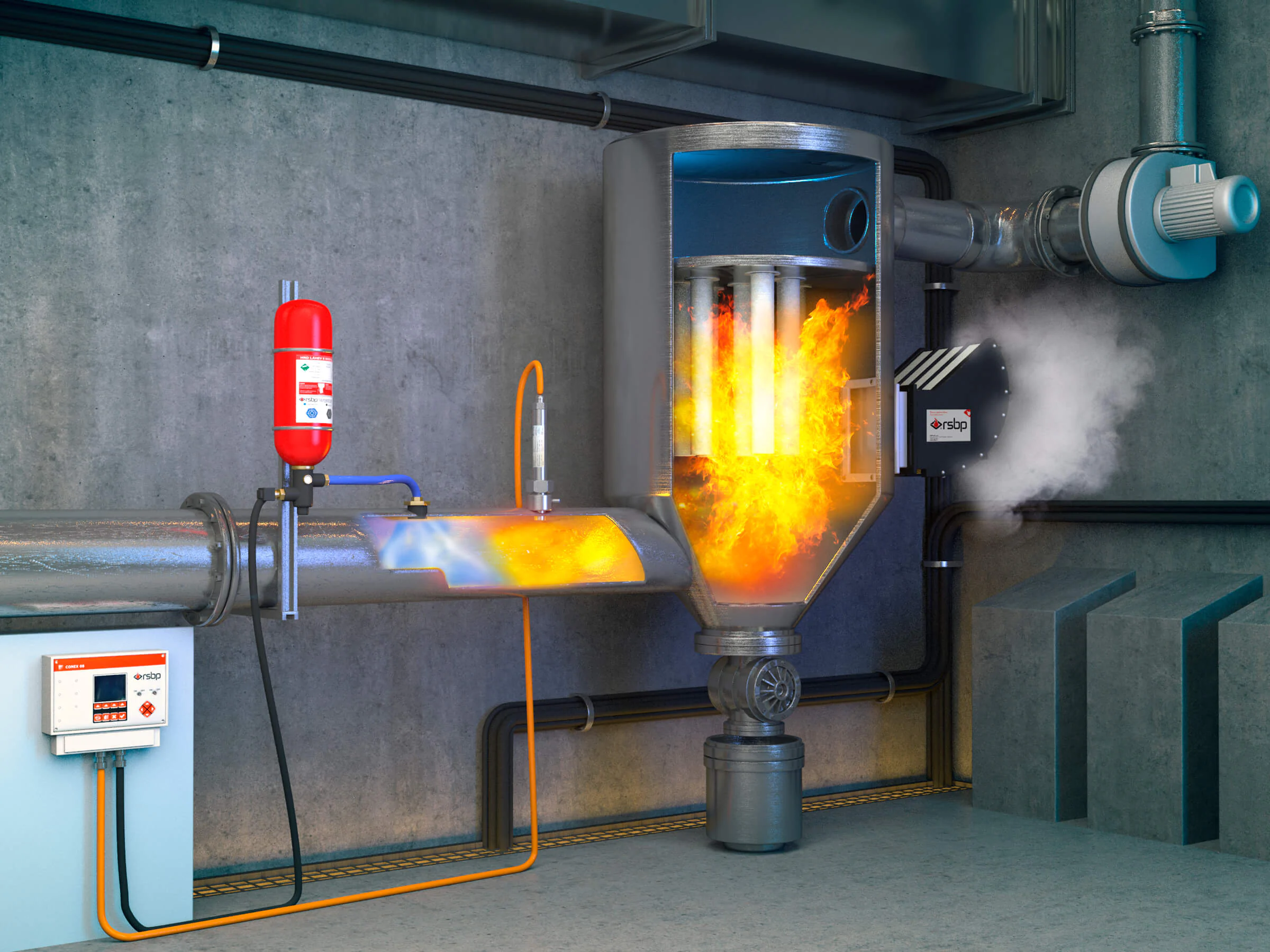

Combustible dust is a hazard in metallurgy, woodworking, food processing and pharmaceutical production. Combined with air, it forms an explosive aerosol suspension which, on contact with an ignition source, leads to an explosion. First localised and then secondary, with widespread destruction.

Dust, air and ignition sources are present in every production facility. Therefore there is always a risk of explosion. Dust testing helps to accurately assess the risk because its explosion and fire hazard properties depend on the presence of specific substances in it.

Operating companies are not always able to carry out the studies themselves. A 'controlled explosion' is needed to determine several dust parameters, which can only be safely arranged at a test site.

Explosion protection in production facilities has its own requirements:

- ATEX 114 (2014/34/EU) — establishes the employer's obligation to protect people against explosion;

- IEC 60079-10-2:2015 - gives definitions of combustible dust and explosive dust environments and sets out the classification of explosive zones;

- EN 1127-1-2014 - describes ignition sources;

- ATEX 114 (2014/34/EU) - contains requirements for equipment for use in potentially explosive environments.

National legislation also establishes its own specificities in technical regulation.

Regulations require that the owner of a hazardous facility must carry out a risk analysis of the workplace and take measures for explosion prevention and explosion protection. Dust testing is the first step to fulfil this obligation.

Dust testing will allow planning of explosion prevention and explosion protection measures, resulting in:

- significant reduction of accident risk for the owner of the hazardous facility and protection of personnel and equipment against explosion;

- the owner prevents losses from destruction of capital facilities, payments to victims;

- the owner complies with industrial safety rules and avoids administrative sanctions.

Dust testing traditionally includes:

- laboratory analysis of dust to determine dispersity, humidity, smouldering and ignition temperatures, and other parameters;

- a series of experimental explosions in an explosion chamber.

Each laboratory is accredited for its own test area, so it is not always possible to carry out all tests in one place. We cooperate with leading institutes in the field of explosion protection from various countries and can arrange dust analysis even for rare substances. We can accurately determine the parameters of airborne dusts in your plant and their flame propagation limits.

ATEX.CENTER is an official partner of RSBP spol. s r.o., a Czech company with 30 years' experience in explosion protection. RSBP has its own research and development facility, where we organise "controlled explosions".

Why do you need a dust test?

In the fast-paced world of industrial production, ensuring workplace safety is paramount. One crucial aspect often overlooked is the potential hazards posed by combustible dust. To address this concern, our comprehensive dust testing services are designed to evaluate and mitigate the risks associated with dust accumulation in various production environments.

Equipments

State-of-the-art equipment is specifically tailored for thorough dust explosion testing, offering unparalleled precision and reliability. By conducting rigorous dust tests, we help you identify and assess the combustibility of particulate matter in your facility, ensuring compliance with industry standards and regulations. From manufacturing plants to processing units, our services cater to a diverse range of industries.

Key Features:

- Cutting-edge Technology: Our advanced testing methods utilize cutting-edge technology to analyze dust samples with precision, providing you with accurate insights into potential risks.

- Customized Solutions: We understand that different industries have unique needs. Tailored dust testing services cater to your specific production environment, ensuring a comprehensive assessment.

- Regulatory Compliance: Stay ahead of regulatory requirements by conducting dust tests. Our services assist you in meeting and exceeding safety standards, thereby safeguarding your workforce and assets.

The dust test is not just a compliance measure; it's a strategic investment in the longevity and safety of your operations. Testing not only helps prevent catastrophic dust explosions but also contributes to a more resilient and efficient production process.

Don't wait for risks to materialize – be proactive with our combustible dust testing solutions. Elevate your workplace safety standards, enhance operational efficiency, and ensure the long-term success of your enterprise. Contact us today for a consultation and take the first step towards a safer, more secure future!