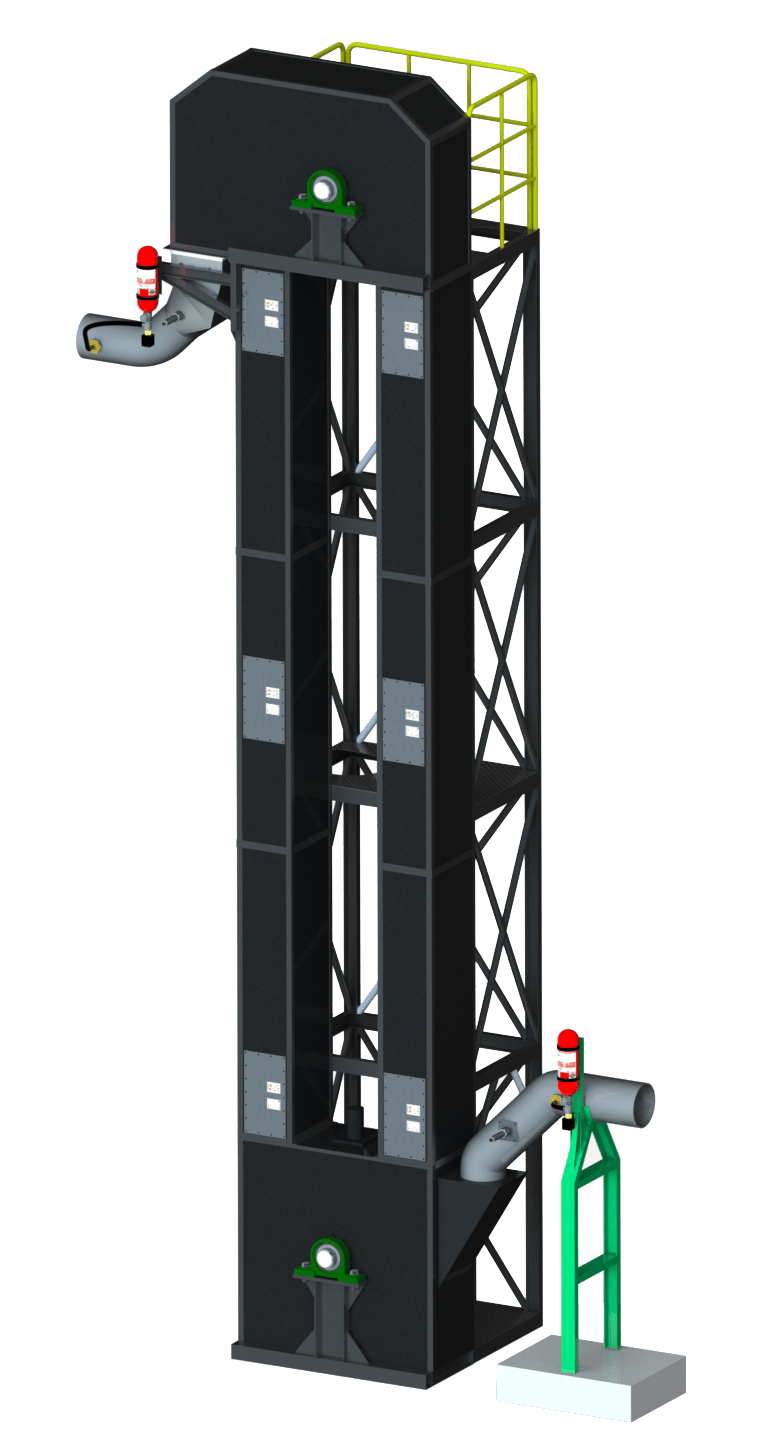

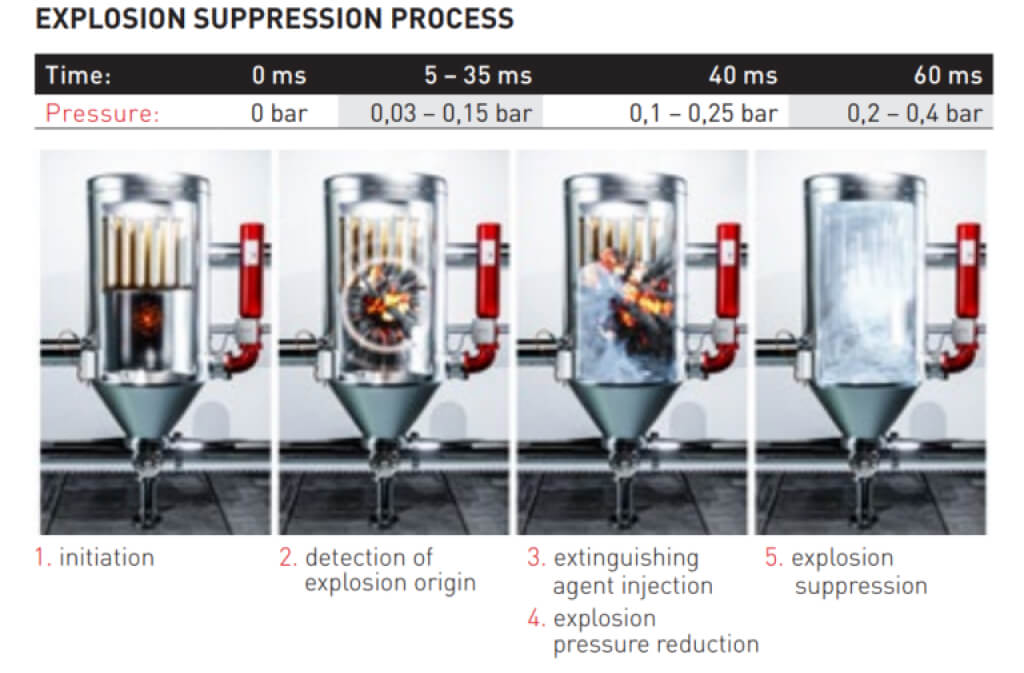

HRD (High Rate Discharge) detects an explosion in equipment at an early stage by means of highly sensitive sensors and suppresses it effectively by applying an explosive suppressant.

The parameters of the dust/air mixture will change as soon as an explosion occurs. Highly sensitive sensors react to changes in pressure and temperature and transmit an alarm signal to the controller. This triggers the activation of the HRD cylinders in the potentially explosive area. This prevents the development of a secondary explosion, which usually leads to devastating consequences.

The main elements of the hrd system:

- Detectors consisting of a sensor, a sensor and a contactor. They continuously monitor and register the occurrence of an explosion in the process equipment and transmit a signal to the control centre (controller). Depending on the operating conditions the hrd system is equipped with optical sensors reacting to infrared radiation or pressure sensors.

- CONEX controller. This is the control centre that processes the signals from the detectors and transmits the commands for activating the HRD containers with the explosive liquid.

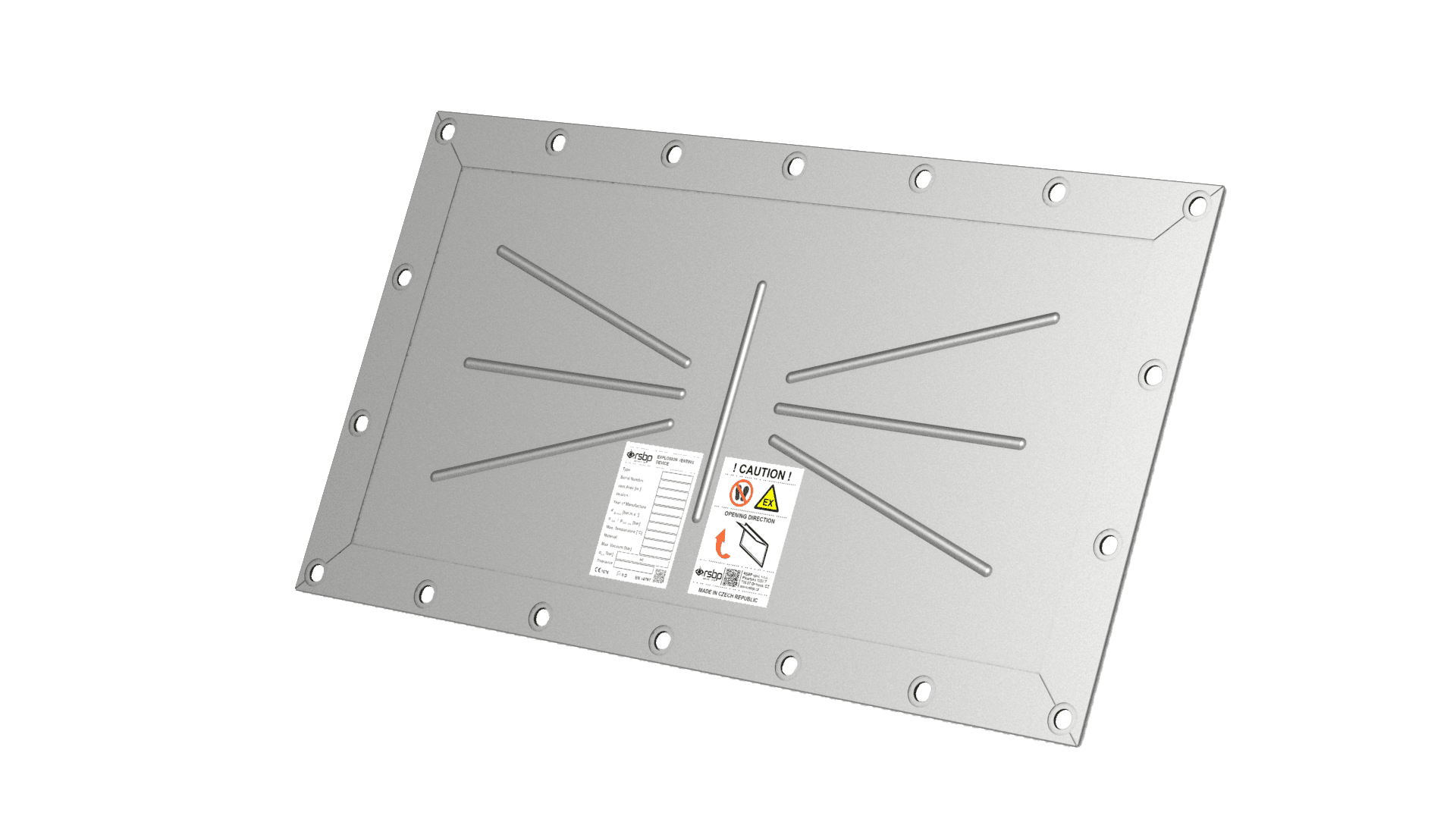

- HRD cylinder (tank) with extinguishing agent. When an explosion occurs and is detected, a pressure generator is actuated, which releases the safety device and opens the opening in the valve mouth. Compressed gas is used to release an extinguishing agent into the process equipment in order to prevent or suppress an explosion. As a result, the pressure is reduced to a safe level and an accident does not occur. The process takes no more than 60 ms. The HRD tank nozzle is telescopic and covered with a rupture disk. Depending on the operating conditions the diaphragms can be made of stainless steel or Teflon. When an HRD cylinder is activated, the flow of explosive suppressant pushes the nozzle inside the equipment. This design eliminates impact on the process during normal operation and protects against contamination.

- Suppresses explosions quickly – no more than 60 ms elapses between detection and application of the suppressant. Explosion products do not escape from the equipment.

- Easy to assemble – installation consists of only two steps, according to ready-made drawing sets and assembly instructions.

- Easy to maintain – we will provide a detailed instruction manual, describing the frequency of all operations. The customer’s employees are only required to visually check the cleanliness and integrity of the components and check the pressure on the HRD cylinders monthly.

- Can be applied to most technological processes at storage and processing facilities of vegetable raw materials.

- Can be installed without changing the design of existing technological equipment.

- Can be used in open areas and enclosed spaces.

- Active components (HRD cylinders) are easy to replace after use.