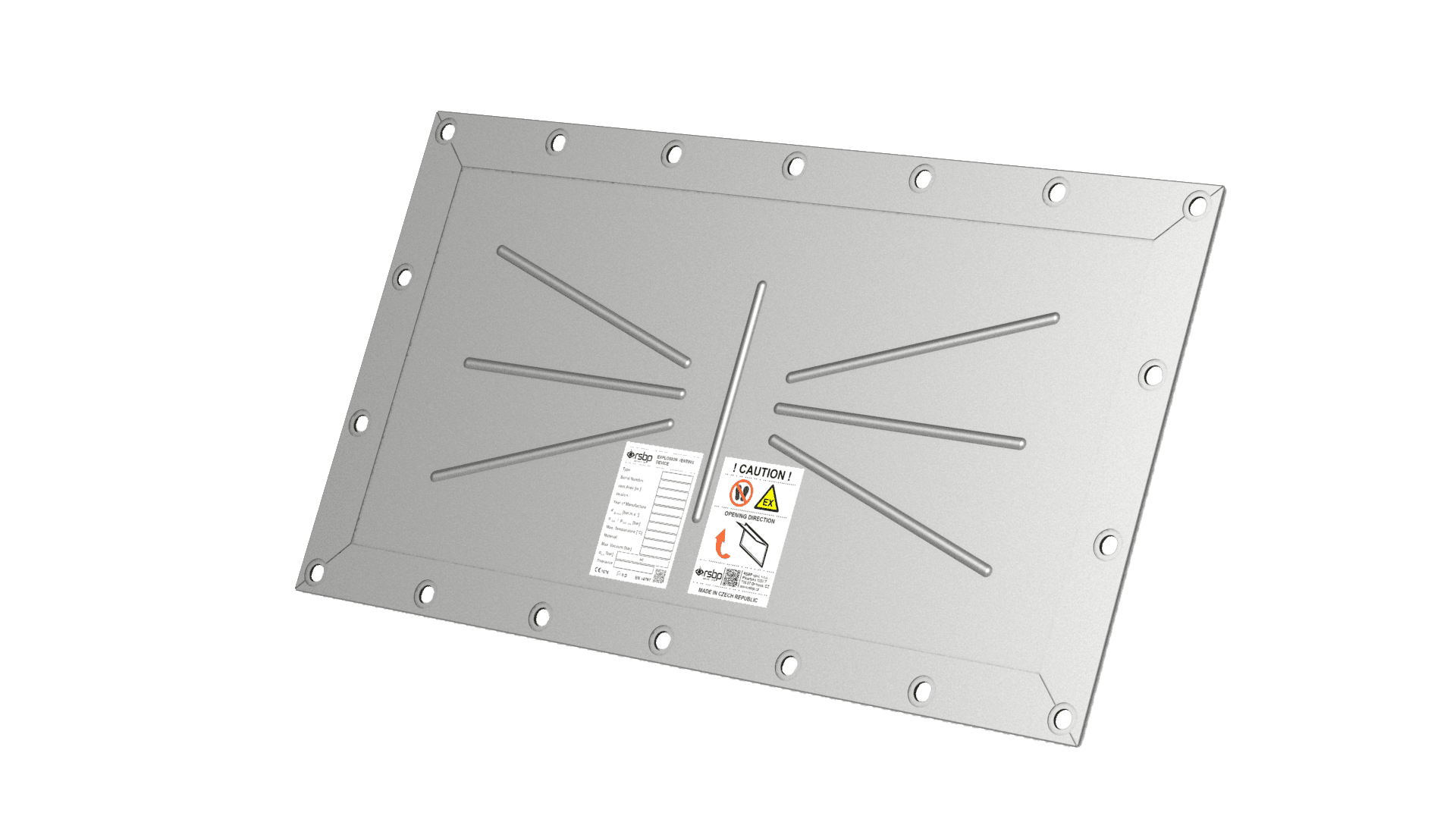

After the cards: European explosion protection standard EN 1127-1 provides for the use of bursting disks, venting hatches or opening panels (doors) to release explosion pressure. Valves are not used in such a protection system.

The required total area of the explosion release holes depends, among other things, on:

- On the strength of the enclosure of the equipment to be protected;

- The intensity of an explosion in a specific dust/air environment;

- The operating pressure of the explosion detectors;

- The volume and geometry of the enclosure of the equipment to be protected.

Explosion dischargers are used where the discharge of shock wave and flame does not threaten the safety of people, other devices. These are, above all, outdoor areas. When used in enclosed areas, explosion dischargers are installed together with flame arresters.

The experts at ATEX.CENTER will carry out an explosion analysis at the customer’s plant and design a passive explosion protection system.

ATEX.CENTER Dust explosion protection solutions across various industries, ensuring safety and continuity. From Explosion protection for energy production facilities and chemical/pharmaceutical production to foodstuffs, metalworking, wood processing, and agricultural sectors, our expertise secures your operations against potential hazards, guaranteeing peace of mind and uninterrupted productivity.