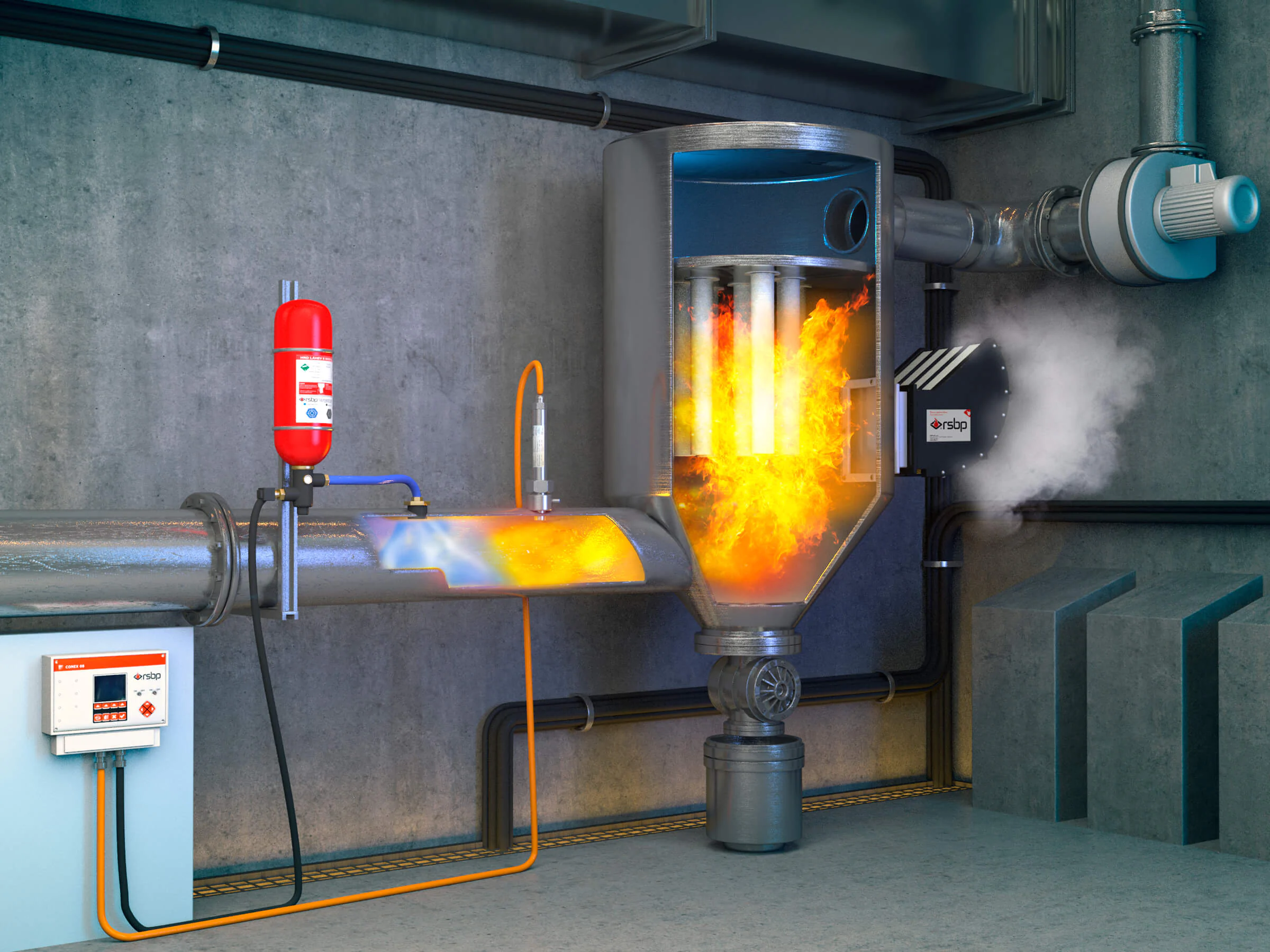

A primary explosion in a pneumatic conveying system usually results in a series of secondary destructive explosions. In branched pipelines and storage tanks, there is an almost ideal environment for an accident: a confined space, airflow for the rapid spread of combustion and enough explosive dust/air mixtures.

The problem is not even that pneumatic conveying systems burn and explode. An accident in them quickly spreads to adjacent pieces of process equipment, leading to their destruction as well as to possible loss of life.

Sources of explosion initiation

According to EN 1127-1-2014 there are 13 active ignition sources which, in contact with a combustible dust/air mixture, may cause an accident.

In pneumatic conveying systems, ignition may be caused by:

- mechanical sparks from friction of particles of the transported material, including metal objects;

- heating of certain sections of the pipeline;

- hot particles in the transported material;

- self-heating in dust deposits;

- discharge of static electricity;

- sparks when the electric motor is switched on, etc.

The list of hazards in pneumatic conveying systems is long. The list of hazards in pneumatic conveying systems is long, and explosion risks cannot be completely ruled out - the risk is linked to the very process of moving bulk solids within the confined space of the material pipelines.

Safety standards for the owner of a hazardous industrial facility

Pneumatic conveying systems with an explosive dust/air environment are classified as Hazardous Industrial Facilities (HIFs). According to European Directive 99/92/EC, their operation must:

- Assess the risks taking into account the likelihood of explosive atmospheres;

- Classify and mark hazardous areas;

- Installation of explosion protection devices on the equipment.

The general requirements of Directive 99/92/EC are specified in national legislation.

The specific requirements for the classification and protection of hazardous areas and the technical equipment used in them are laid down in the ATEX standards. These are EN 1127-1, IEC 60079-10-2-2011 with general requirements and the special EN 15089, EN 16447, EN 14373, EN 16009.

Technical solutions

Explosion protection systems are selected on the basis of the operating conditions and the nature of the material to be conveyed. We therefore first determine the Ex zone class and the required protection level according to IEC 60079-10-2-2011.

For this purpose, we take combustible dusts for laboratory tests under "controlled explosion conditions". As a result, we determine the explosion hazard parameters of the production facility:

- Low Explosion Level / LEL

- Maximum rate of explosion pressure rise / (dp/dt)max

- explosion class / Kst

- Minimum explosion temperature / MIT

- Minimum ignition temperature / GT

- Minimum explosion energy / MIE

- Oxygen concentration limit / LOC

Based on this data, we select specific explosion protection equipment.

For pneumatic conveying systems, the best solution is to contain and isolate the explosion to prevent it spreading to adjacent pipeline sections and neighbouring equipment.